Buried pipe ground temperature measuring device and measuring methods

A measurement method and technology for buried pipes, which are applied in directions such as thermometers that give average/integrated values, can solve the problems of large test point spacing, high test cost, rough initial temperature, etc., so as to improve test accuracy and reduce test cost. low effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

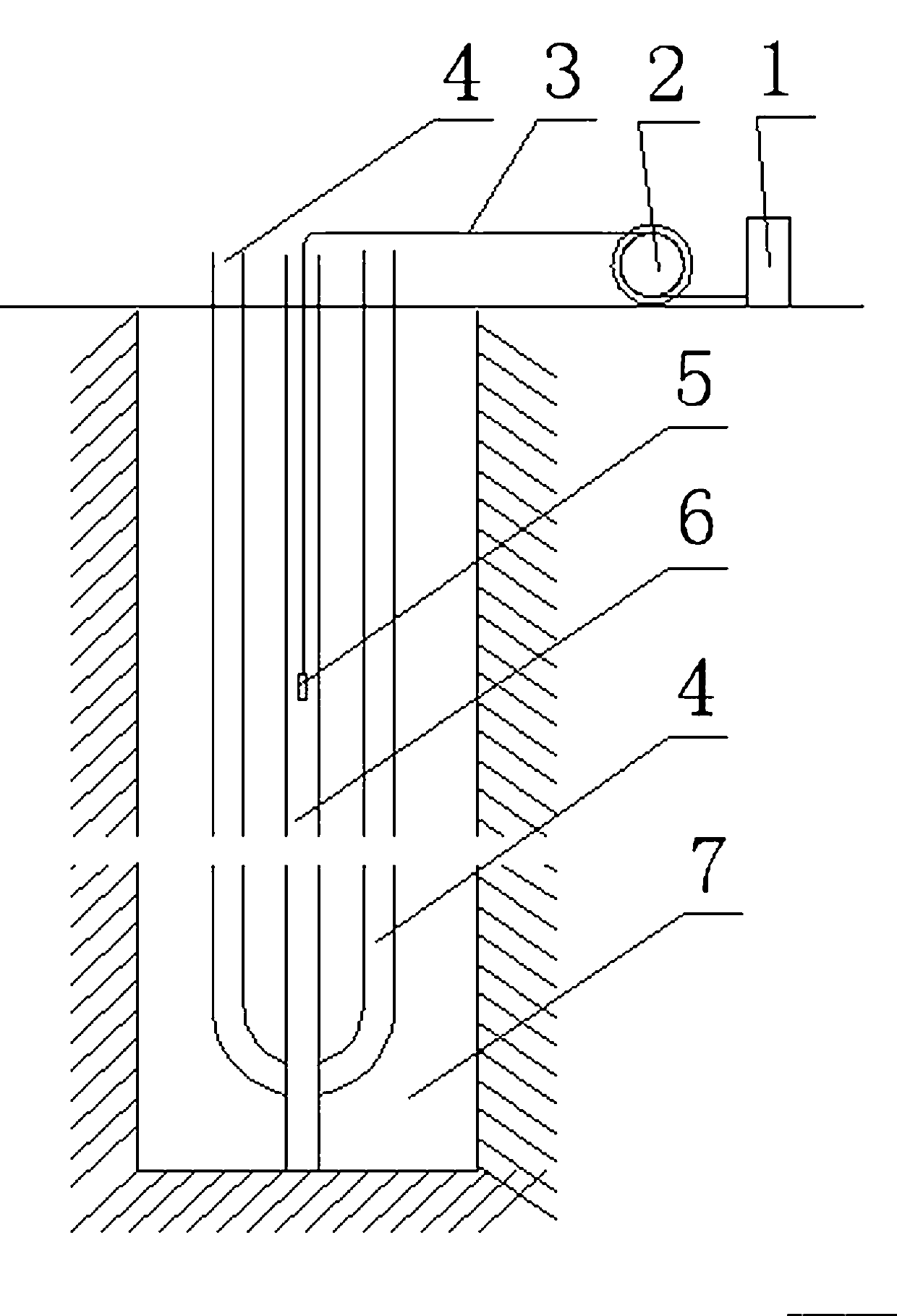

[0044] Embodiment one: if figure 1 As shown, the first method for measuring the ground temperature of the buried pipe is characterized in that it comprises the following steps:

[0045] a. Prepare a temperature measuring tube 6 equal in length to the heat exchange tube 4, and put the temperature sensor 5 and the cable 3 connected thereto into the temperature measuring tube 6 in advance;

[0046] b. After the drilling 7 is completed, put the temperature measuring tube 6 and the heat exchange tube 4 side by side into the test hole 7, the temperature sensor 5 is located at the lowermost end of the temperature measuring tube 6, backfill the tube, and let it stand for at least 48 hours;

[0047] c. Connect the cable 3 of the temperature sensor 5 and the data logger 1, and start the data logger 1;

[0048] d. Move the temperature sensor 5 upwards at a constant speed along the direction of the pipeline in the temperature measuring tube 6, and observe whether the data recorder 1 re...

Embodiment 2

[0053] Embodiment two: if figure 1 As shown, the first method for measuring the ground temperature of the buried pipe is characterized in that it comprises the following steps:

[0054] a. Prepare a temperature measuring tube 6 equal in length to the heat exchange tube 4;

[0055] b. After the drilling 7 is completed, put the temperature measuring tube 6 and the heat exchange tube 4 side by side into the test hole 7, backfill the tube, and let it stand for at least 48 hours;

[0056] c. Put the temperature sensor 5 into the top inlet of the temperature measuring tube 6, and start the data recorder 1;

[0057] d. Move the temperature sensor 5 downward at a constant speed along the direction of the pipeline in the temperature measuring tube 6, and observe whether the data recorder 1 records and stores the temperature data normally;

[0058] e. When the temperature sensor 5 reaches the bottom of the temperature measuring tube 6, stop recording and storing the temperature data;...

Embodiment 3

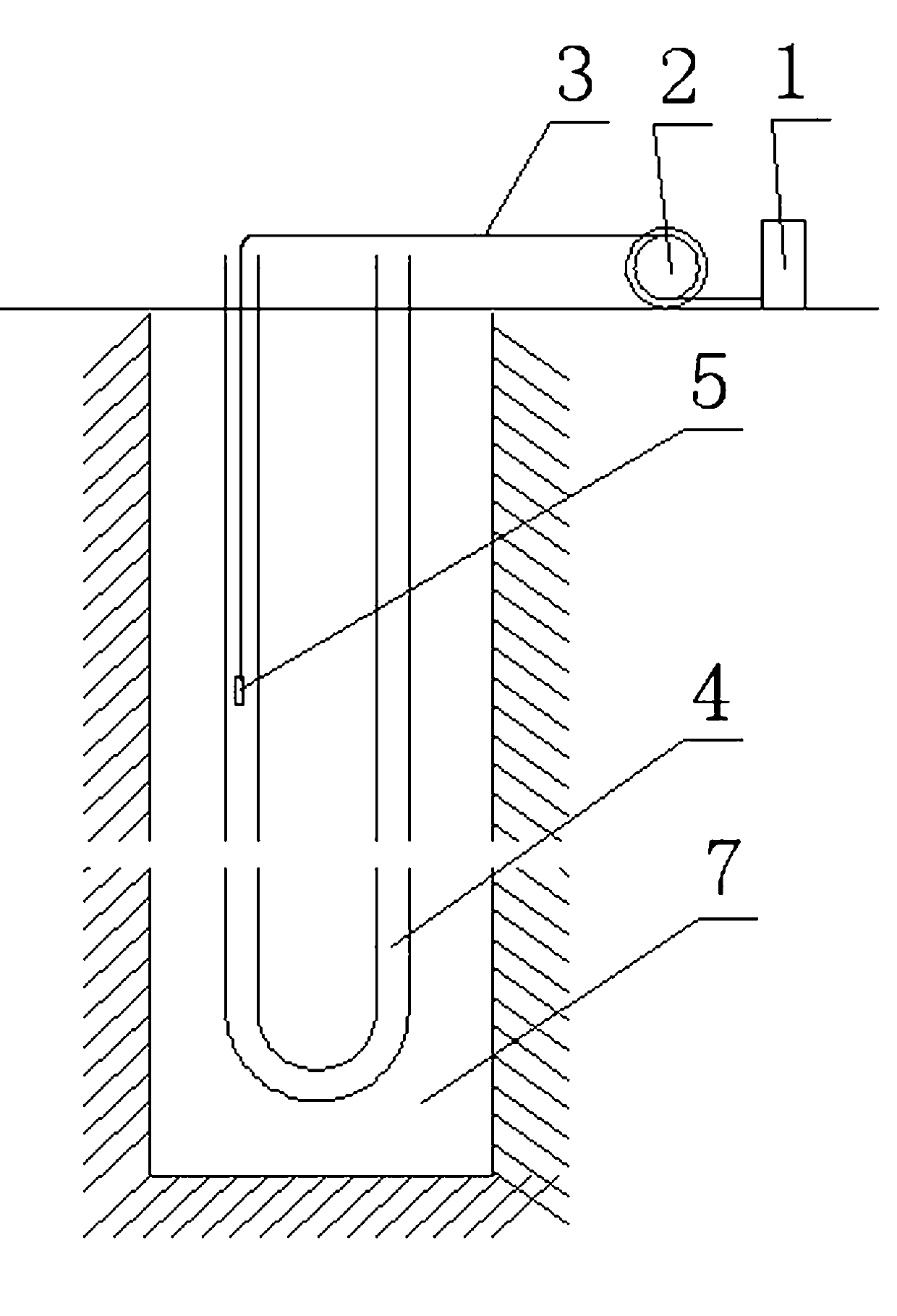

[0062] Embodiment three: as figure 2 As shown, the second method for measuring the ground temperature of the buried pipe is characterized in that it includes the following steps:

[0063] a. Thread the temperature sensor 5 and the cable 3 connected thereto into the heat exchange tube 4 in advance;

[0064] b. After the drilling 7 is completed, put the heat exchange tube 4 together with the temperature sensor 5 and the cable 3 into the test hole 7. The temperature sensor 5 is located at the bottom guide of the buried tube heat exchanger 4, and backfill Bury the pipe and let it stand for at least 48 hours;

[0065] c. Connect the cable 3 of the temperature sensor 5 and the data logger 1, and start the data logger 1;

[0066] d. Move the temperature sensor 5 upward at a constant speed along the direction of the pipe in the heat exchange pipe 4, and observe whether the data recorder 1 records and stores the temperature data normally;

[0067] e. When the temperature sensor 5 r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com