Connecting pin appressed type miniature connector

A micro-connector, flat paste technology, applied in the direction of connection, connection parts installation, connection device components, etc., can solve the problems of inability to use plastic hard shell, frequent repeated insertion and removal of plugs, protection, etc., to achieve increased integration The effect of strength and convenience for wire welding operations

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

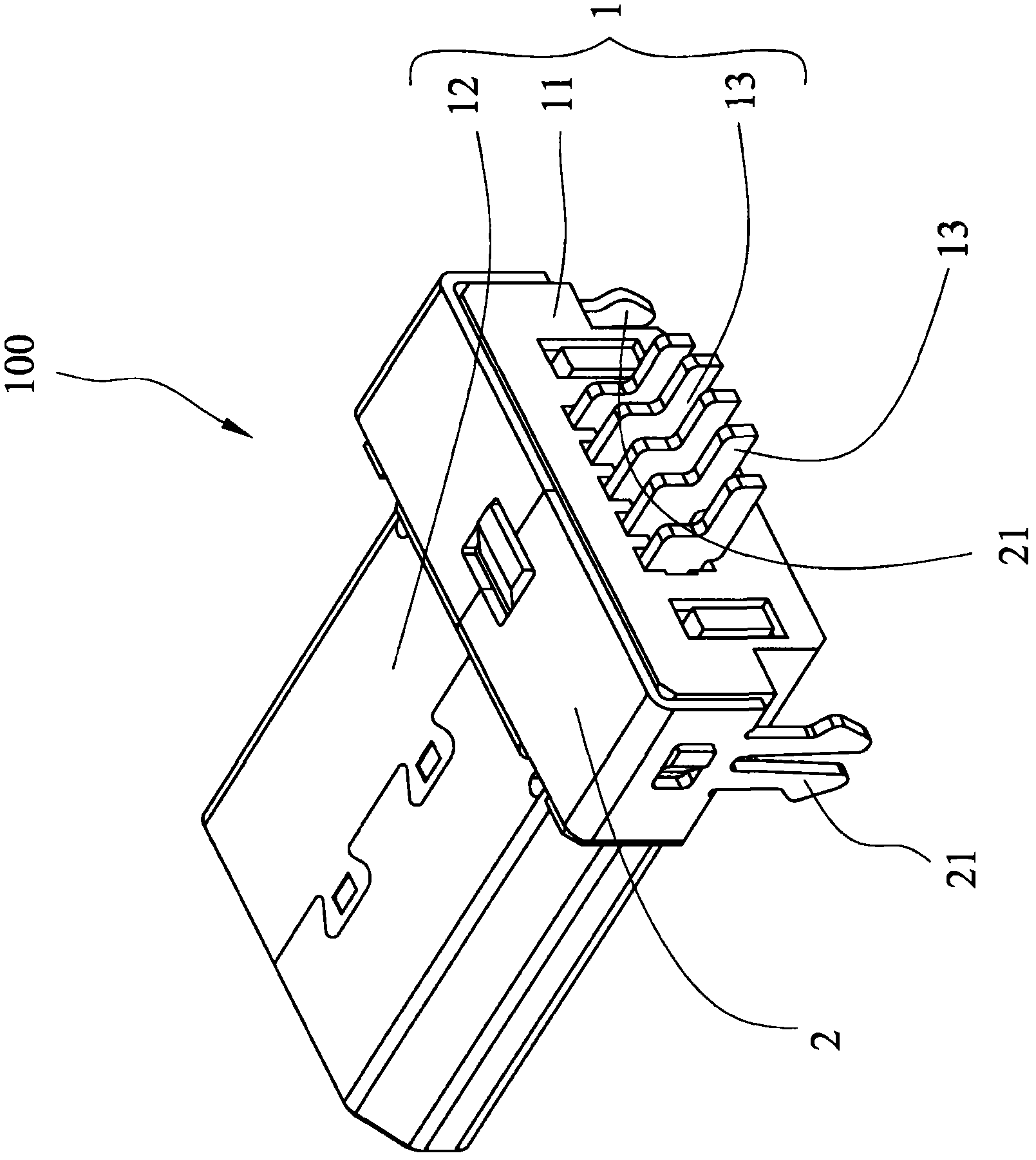

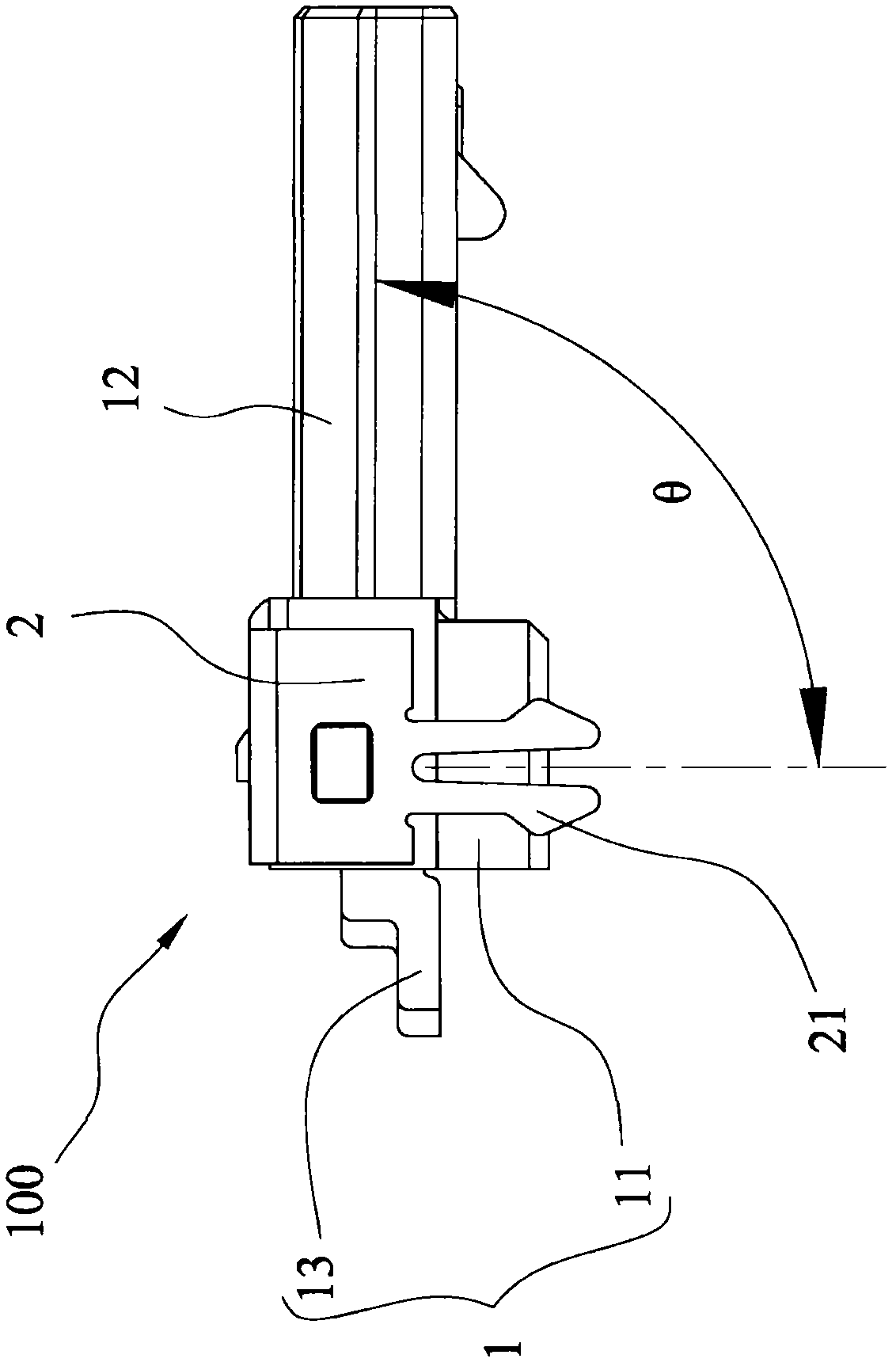

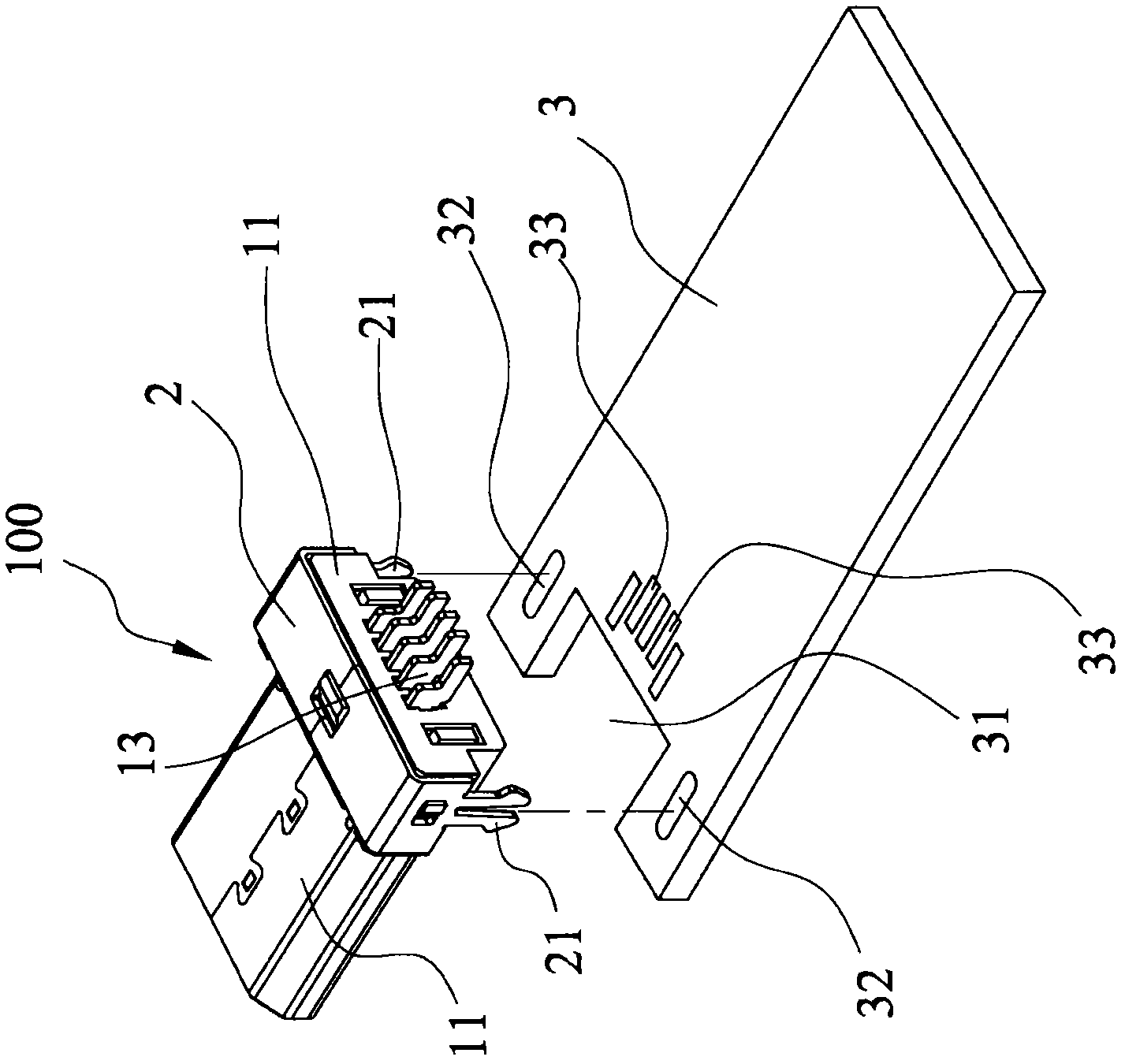

[0024] Such as figure 1 and figure 2 As shown in the perspective view and side view of the present invention, the pin flat-mounted micro connector 100 of the present invention is used to install a Micro USB plug-type connector on a circuit board, and includes: a plug unit 1 and a metal shell 2 , the metal shell is combined with the plug unit 1, so that the micro connector 100 can be easily assembled and a good fixing effect can be obtained.

[0025] Next, the structure of each member of the present invention will be described.

[0026] The plug unit 1 is the basic structure of a Micro USB plug-type connector, including an insulator 11, a plug 12 fixed on the side of the insulator, and a plurality of pins 13 extending from the inside of the insulator 11. The body conforms to the specifications of the current Micro USB plug. The metal terminal of the pin 13 inside the insulator 11 extends into the plug 12 for electrical connection. In this embodiment, the heights and positi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com