Water and fertilizer treatment system of drip irrigation under plastic film on rice

An under-film drip irrigation and treatment system technology, applied in the field of agricultural irrigation, can solve the problems of difficult synchronization of water and fertilizer, fast water flow rate, and difficult sedimentation of suspended sediment, so as to facilitate growth and increase production, reduce labor intensity, and sediment sedimentation Good results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

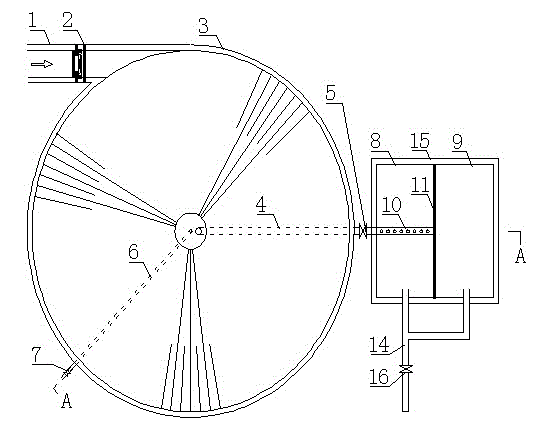

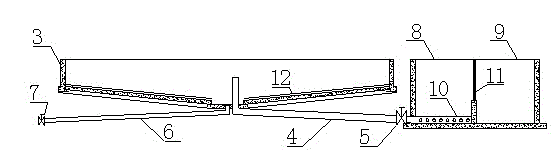

[0019] Such as figure 1 , figure 2 As shown, a kind of drip irrigation water and fertilizer treatment system for rice under mulch film described in Embodiment 1 of the present invention includes a sand removal and warming pool 3 and a water and fertilizer pool 15, and the sand removal and warming pool 3 is cylindrical, and the sand removal and warming pool The water inlet 1 of the pool 3 is connected with the side wall of the desand-increasing pool 3 and is tangent to the surface of the desand-intensifying pool 3. The bottom of the desanding and intensifying pool 3 is provided with a blowdown pipe 6, and the blowdown pipe 6 It is provided with a blowdown valve 7, which is characterized in that: the bottom of the desanding and warming pool 3 is provided with a water outlet pipe 4, and the water inlet end of the water outlet pipe 4 is set at the center of the desanding and warming pool 3, and the height of the water inlet end of the water outlet pipe 4 is high. At the height o...

Embodiment 2

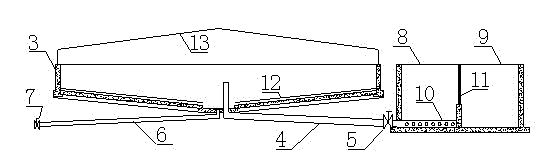

[0026] Such as image 3 As shown, the difference from Embodiment 1 is that a warming shed 13 is provided above the desanding and warming pool 3, and the warming shed 13 is a light-colored or dark-colored plastic film, which is heated and kept warm by absorbing solar energy. , covered on the desanding warming pool 3.

[0027] The water and fertilizer treatment system for rice under-film drip irrigation according to the invention can increase the irrigation water temperature of rice under-film drip irrigation by 2-5°C.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com