Cambered waist for female trousers and making method

An arc-shaped waist and waist lining technology, applied in the field of garment processing, can solve the problems of irregular texture of the arc-shaped waist fabric, inability to fit the human body, poor wearing comfort, etc. smooth effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

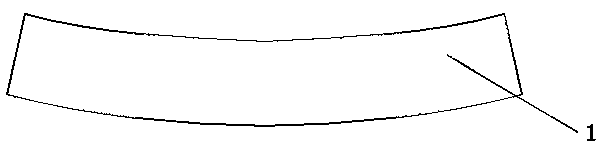

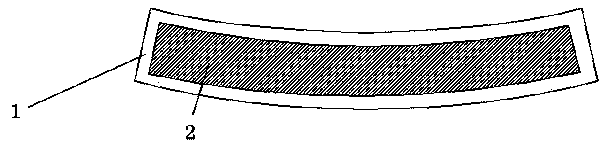

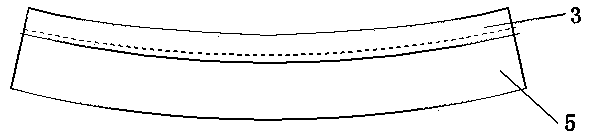

[0029] see Figure 1~Figure 5 , the invention relates to a curved waist for women's trousers, which includes a waist and a waist sewn together, and the waist includes a waist base fabric 1 and an elastic waist lining 2 bonded to the back of the waist base fabric 1 , the elastic waist lining 2 includes a base material, the base material is polyester or chemical fiber embedded with rubber threads, the rubber threads in the elastic waist lining 2 become thinner from the upper mouth to the lower mouth, and the upper and lower sides of the base material The surface is provided with a rubber surface, and the waist includes a waist-wrapping polyester-cotton cloth 3, a resin waist lining 4 and an edge-wrapping polyester-cotton cloth 5 sewn together, and the waist-wrapping polyester-cotton cloth 3 bypasses the lower edge of the resin waist lining 4 to The resin waist lining 4 is wrapped inside, and the waist-wrapping polyester-cotton cloth 3 and the edge-wrapping polyester-cotton cloth...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com