Ink supply system of ink jet printer and control method of ink supply system

An inkjet printer and ink supply technology, applied in printing and other fields, can solve problems such as imperfect design, increased production cost of inkjet printers, unstable ink supply system, etc., achieve stable printing effect, reduce deposition clogging, reduce printing glitch effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] In order to make the object, technical solution and advantages of the present invention more clear and definite, the present invention will be further described in detail below with reference to the accompanying drawings and examples.

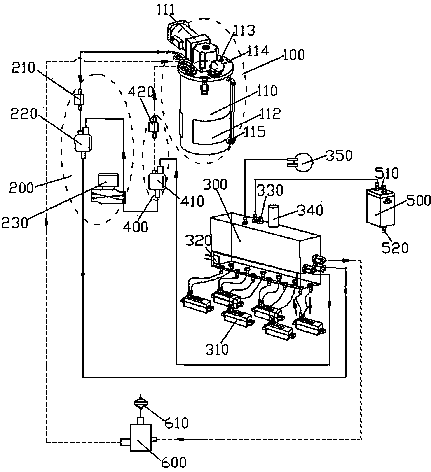

[0037] Such as figure 1 Shown is a structural schematic diagram of the ink supply system of the inkjet printer. The ink supply system of the inkjet printer includes an ink barrel device 100 for stirring and heating the ink, an ink filling and circulation device 200 for continuously circulating the supply circuit ink, an ink cartridge 300 for reducing ink deposition, and a defoaming device 400 for eliminating ink bubbles and control System; the ink barrel device 100 includes an ink barrel body 110, the ink barrel body 110 is provided with an ink supply port and an ink return port, and the ink barrel body is provided with a stirring device 111, a first heating device 112 and a first temperature detection device 113; the ink filling and ci...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com