Telescopic single column transport vehicle

A single-column, transport vehicle technology, applied in the direction of transportation and packaging, trolleys, motor vehicles, etc., can solve the problems of affecting the work progress, fixed size, inability to adjust, etc., to achieve the effect of convenient transportation and prevention of rolling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

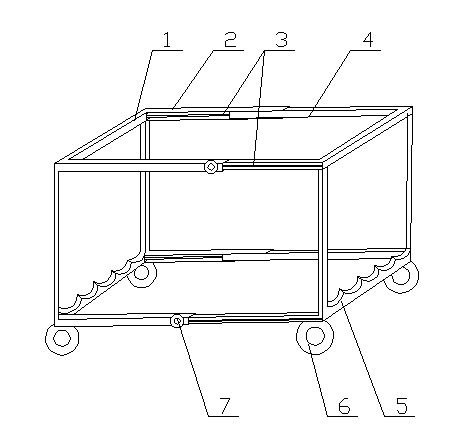

[0010] In the accompanying drawings, the telescopic monocolumn transport vehicle includes a car body 1, a fixed car body 2, a track 3, a movable car body 4, a limit beam 5, a universal wheel 6 and a fastening knob 7; There is a rectangular parallelepiped frame-type vehicle body 1; universal wheels 6 are fixedly installed at the four corners of the bottom of the vehicle body 1 to facilitate the movement of the transport vehicle; and the movable car body 4; the upper and lower beam inner sides on both sides of the fixed car body 2 and the outer sides of the upper and lower beams on both sides of the movable car body 4 are correspondingly provided with a track 3 for anastomosing sliding fit connection; the fixed The outer sides of the upper and lower beams on both sides of the car body 2 are also rotatably connected with fastening knobs 7, which can be twisted and tightened to make the movable car body 4 and the fixed car body 2 reliably connected; the front and rear ends of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com