Assembled combined cab of three-wheeled motorcycle

A technology of three-wheeled motorcycles and cabs, applied to the upper structure of trucks, motor vehicles, bicycles, etc., can solve the problems of increased cost, increased number of tooling fixtures, and increased transportation costs, and reduce the cost of tooling fixtures The effect of demand, large quantity of containerized transportation, and simple structure and process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

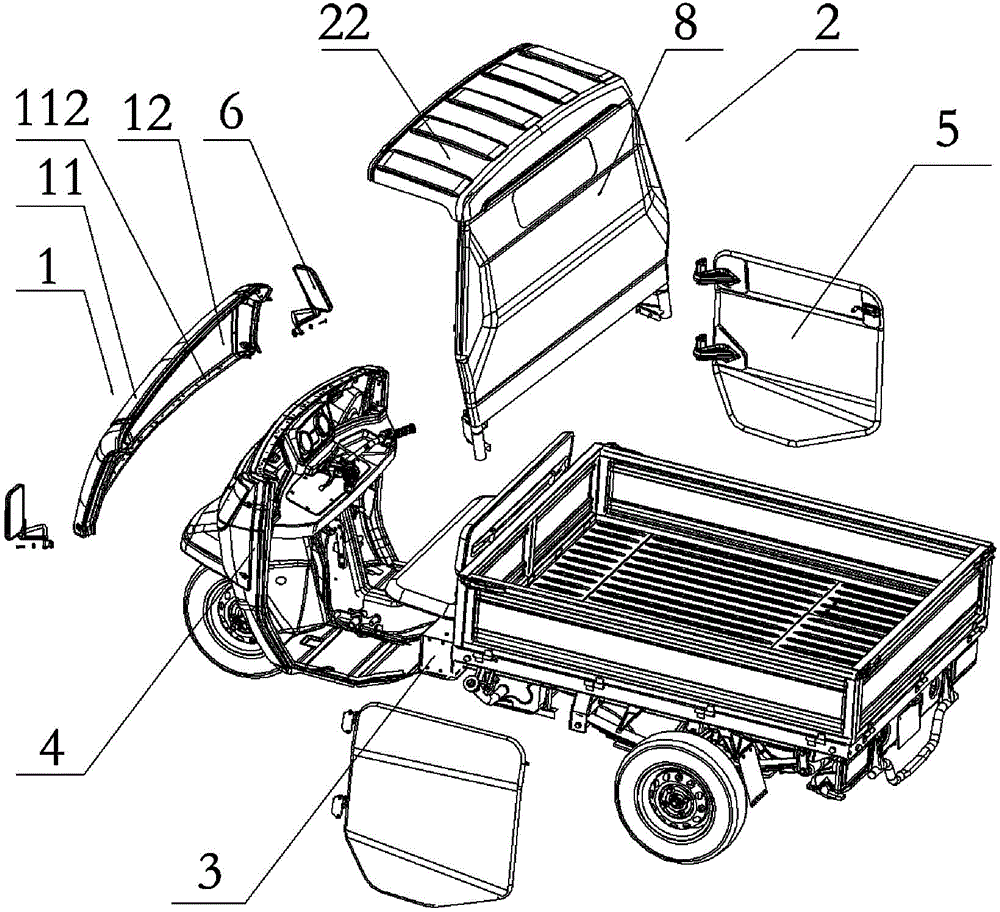

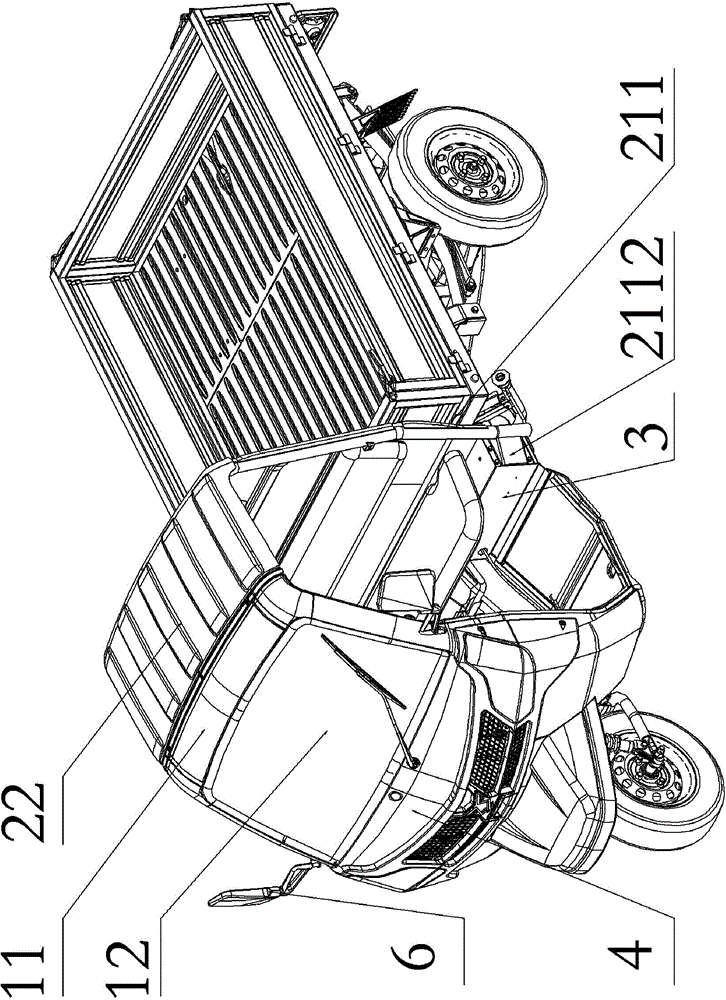

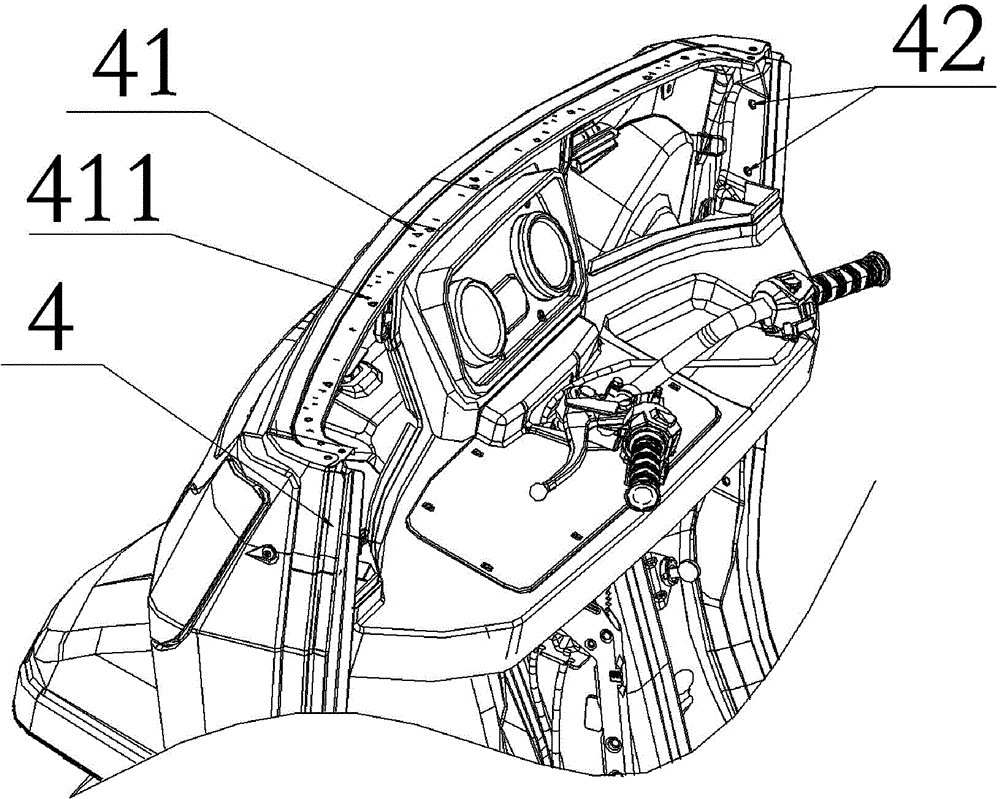

[0036] see Figure 1 to Figure 8 , is an embodiment of the assembled and combined cab of a three-wheeled motorcycle. This assembled and combined cab includes a front windshield assembly 1, a scaffolding combination 2, and a front cross member provided on the three-wheeled motorcycle frame. 3 and cab front panel 4. The front windshield assembly of the cab, the shed combination, and the front panel of the cab are all modules produced separately, and finally spliced and assembled, the structure and process are simpler, and each component occupies less space, which is convenient for assembly transportation. The upper end of the front panel 4 of the cab is formed with a mounting platform 41 for the front windshield device, and the mounting platform 41 is provided with a fixing hole 411 for the front windshield assembly. The bent and formed installation platform makes the installation platform stronger, and the front end of the front panel is equipped with a wiper.

[0037] The...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com