Singeing cleaning roller

A cleaning roller and brush technology, applied in the field of fabric cleaning equipment, can solve the problems of poor cleaning effect, different fabric surface patterns and textures, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] Below in conjunction with accompanying drawing and embodiment the present invention is further described:

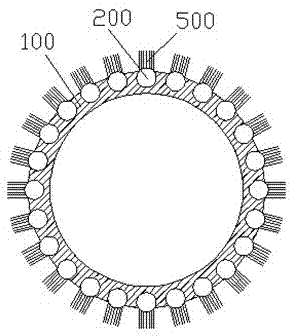

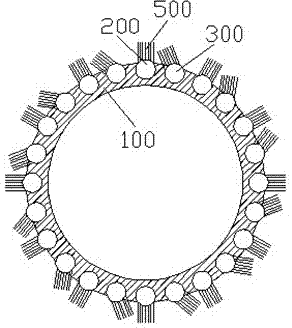

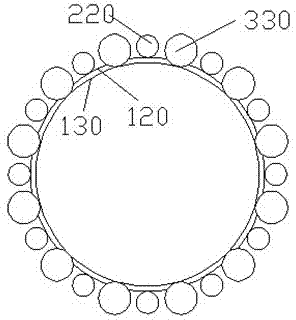

[0017] In this example, see figure 1 and figure 2 , the singeing cleaning roller includes a cleaning roller shaft 100 and a brush bundle 500, the brush bundle 500 is evenly distributed on the surface of the cleaning roller shaft 100 in a rectangular array, and the bottom of the brush bundle 500 is arranged by an eccentric angle adjustment structure On the cleaning roller shaft 100, the brush bundle 500 has two specifications with different eccentric angles.

[0018] refer to figure 2 , the brush bundles 500 of different specifications are arranged at intervals, and the interval arrangement can make the surface of the brush roller undulate regularly, making cleaning more efficient.

[0019] For the above-mentioned singeing cleaning roller, the eccentric angle adjustment structure is a first rotating shaft 200 and a second rotating shaft 300 uniformly distribut...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com