A method of assembling a rotary compressor

A rotary compressor and assembly method technology, applied in the field of compressors, can solve problems such as inability to assemble, limit the freedom of motor size design, etc., achieve the effects of reducing size, improving starting performance, and reducing moment of inertia

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

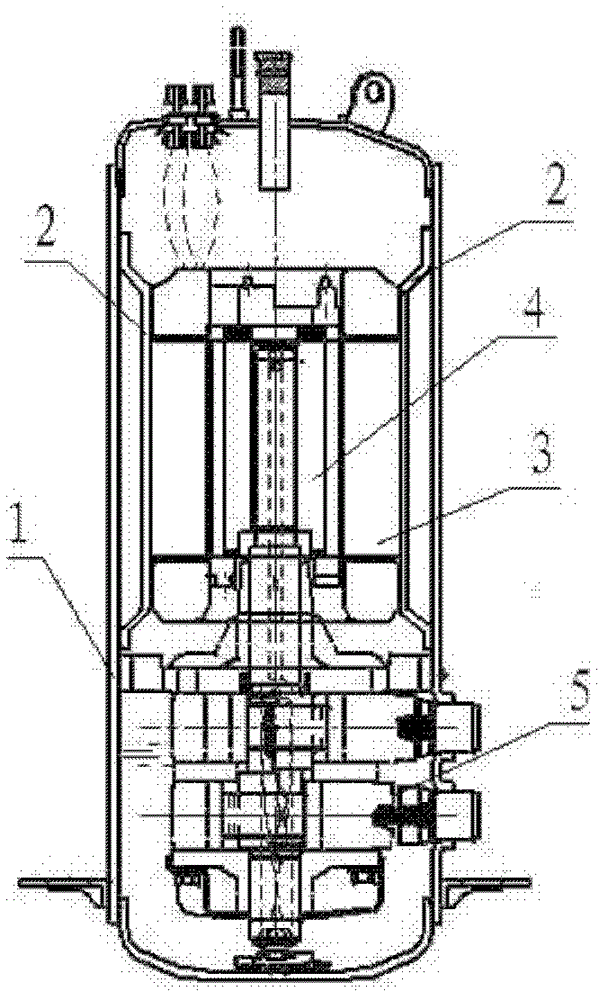

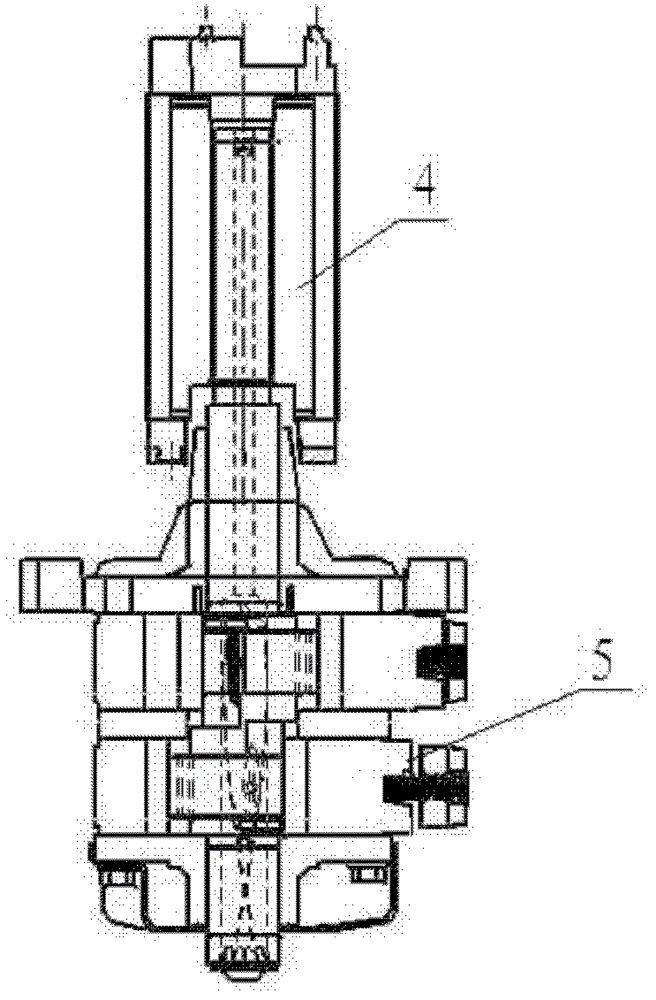

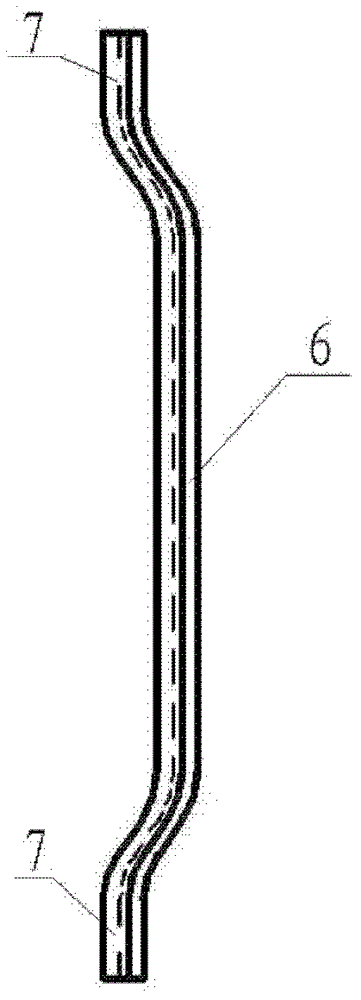

[0027] Such as Figure 1-3 As shown, a rotary compressor includes a housing 1, a motor stator 3, a motor rotor 4 and a pump body assembly 5, and also includes three support frames 2, which are dispersedly arranged on the inner wall of the housing 1, and are formed after being connected with the housing. The housing assembly, each supporting frame 2 is arcuate, including the middle boss 6 and the feet 7 integrally provided at both ends of the boss, the outer diameter of the motor stator 3 is smaller than the inner diameter of the housing 1, and the motor stator 3 is pressed into each supporting frame 2 In the middle, the boss 6 of the support frame 2 is in interference fit with the outer diameter of the motor stator 3, and the legs 7 at both ends are welded on the housing 1, so that the motor stator 3 is fixed in the housing 1 through the support frame 2. The motor rotor 4 is inserted into the inner hole of the motor stator 3, and the pump body assembly 5 is welded on the casin...

Embodiment 2

[0037] Six supporting frames are set according to the shape of the motor stator, and the rest are the same as in Embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com