Two-way control low-friction cylinder

A low-friction, cylinder technology, used in fluid pressure actuation devices and other directions, can solve the problems of inability to reduce energy consumption, shortened cylinder life, and unstable cylinder output force, and achieve increased service life, good sealing performance, and high accuracy. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

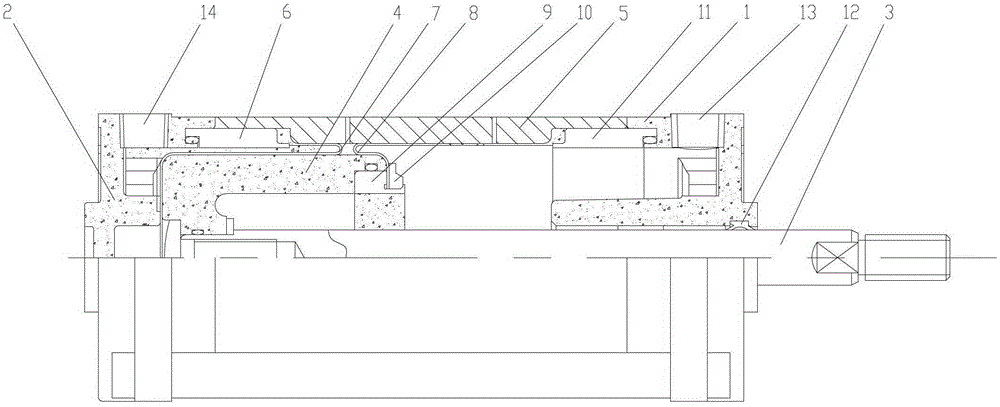

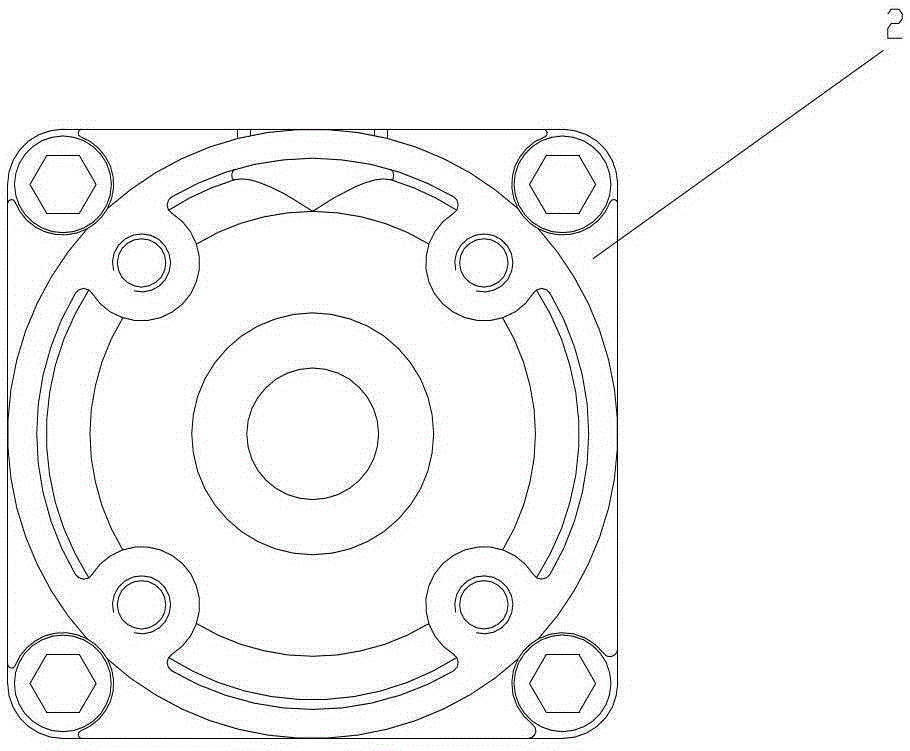

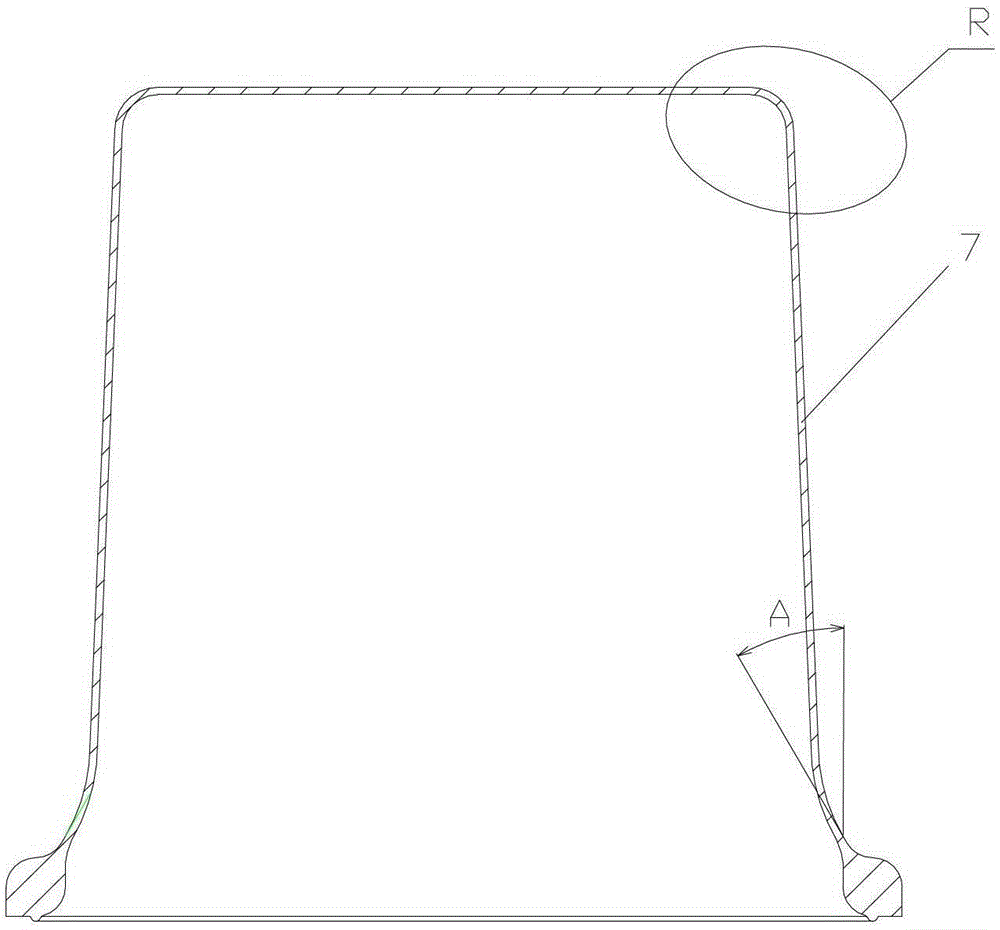

[0039] like figure 1 and figure 2 As shown, in the dual-way control low-friction cylinder of the present invention, the left and right end covers of the cylinder body 5 are the hood F1 and the hood R2; The upper end diaphragm 8; the opening direction of the lower end diaphragm 7 is fixed on the inner side of one end of the cylinder block 5 through the lower cylinder liner 6, forming a lower diaphragm air cavity with the piston 4; both ends of the upper end diaphragm 8 are open, and one end is opened through the upper The cylinder liner 11 is also fixed on the inner side of the other end of the cylinder block 5, and the opening of the other end is riveted and fixed by the pinch plate A9 and the pinch plate B10, and then pressed into the piston 4 and the piston 4 to form an upper film air cavity; Air cavity exhaust holes F13 and R14 are set co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com