Ultraviolet and visible light double optical axis parallelism calibration device under external field environment

A calibration device and visible light technology, applied in the direction of optical devices, measuring devices, instruments, etc., can solve problems such as the influence of optical axis parallelism, achieve the effects of easy light weight, compact device structure, and improved calibration efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be described in detail below in conjunction with the accompanying drawings.

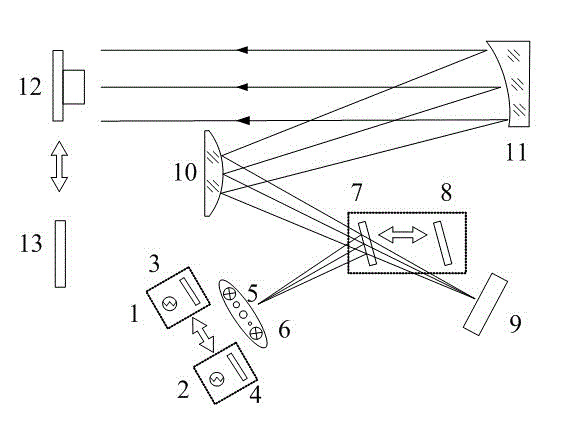

[0019] see figure 1 and figure 2 , a device for calibrating dual optical axes parallelism of ultraviolet and visible light in an external field environment provided by the present invention, including a depth of focus self-calibration component and a radial self-calibration component,

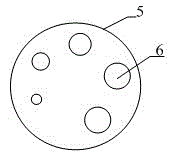

[0020] The depth of focus self-calibration assembly is composed of an ultraviolet light source assembly, a visible light source assembly, an aperture disc 5, a half mirror, a receiving part CCD9, a secondary reflector 10, a main reflector 11, and a reference CCD camera 12. The light source assembly is composed of an ultraviolet light source 1 and an ultraviolet light diffusion plate 3. The visible light source assembly is composed of a visible light source 2 and a visible light diffusion plate 4. The ultraviolet light source assembly and the visible light source assembly are arrange...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com