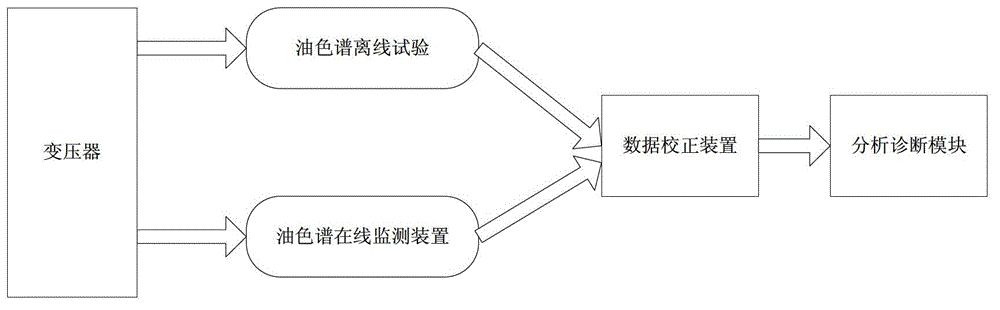

Correction method for on-line monitoring noisy data of oil chromatography

A noise data and correction method technology, applied in the direction of measuring devices, instruments, scientific instruments, etc., can solve the problems of long training time, poor correction effect, over-learning, etc., and achieve stable and accurate results, good real-time performance, and short time effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

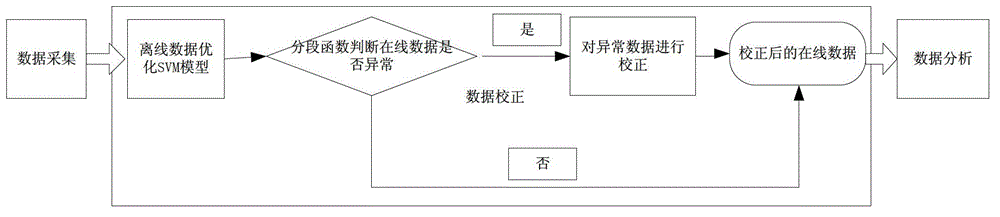

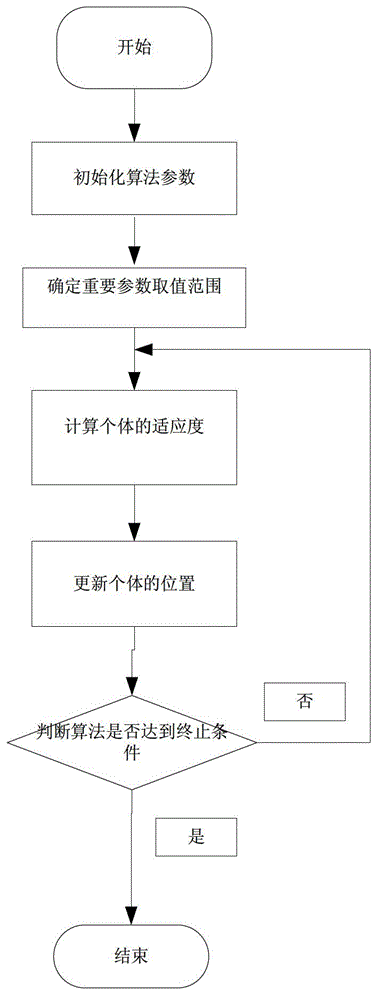

[0031] image 3 It is a flow chart of the firefly algorithm optimization of the important parameters of the support vector machine in the embodiment of the present invention; Figure 4 It is a flow chart of correcting online noise data by a support vector machine regression model according to an embodiment of the present invention. like image 3 , Figure 4 , a kind of oil chromatography on-line monitoring noise data correction method, its method comprises the following steps:

[0032] Step 1), collecting oil chromatography offline test and online monitoring data;

[0033] Step 2) Obtain the optimal combination of important parameters in the support vector machine regression model through the firefly algorithm;

[0034] Step 3), using the small number of accurate off-line test data of oil chromatography obtained in step 1) to train the sup...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com