Knob

A knob and segment technology, applied in the field of knobs, can solve problems such as affecting the performance of electronic products, cracking or slipping of the clamping end, and eccentricity of the rotary switch, so as to prevent breakage or slippage, prevent slippage or failure, Uniform force effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

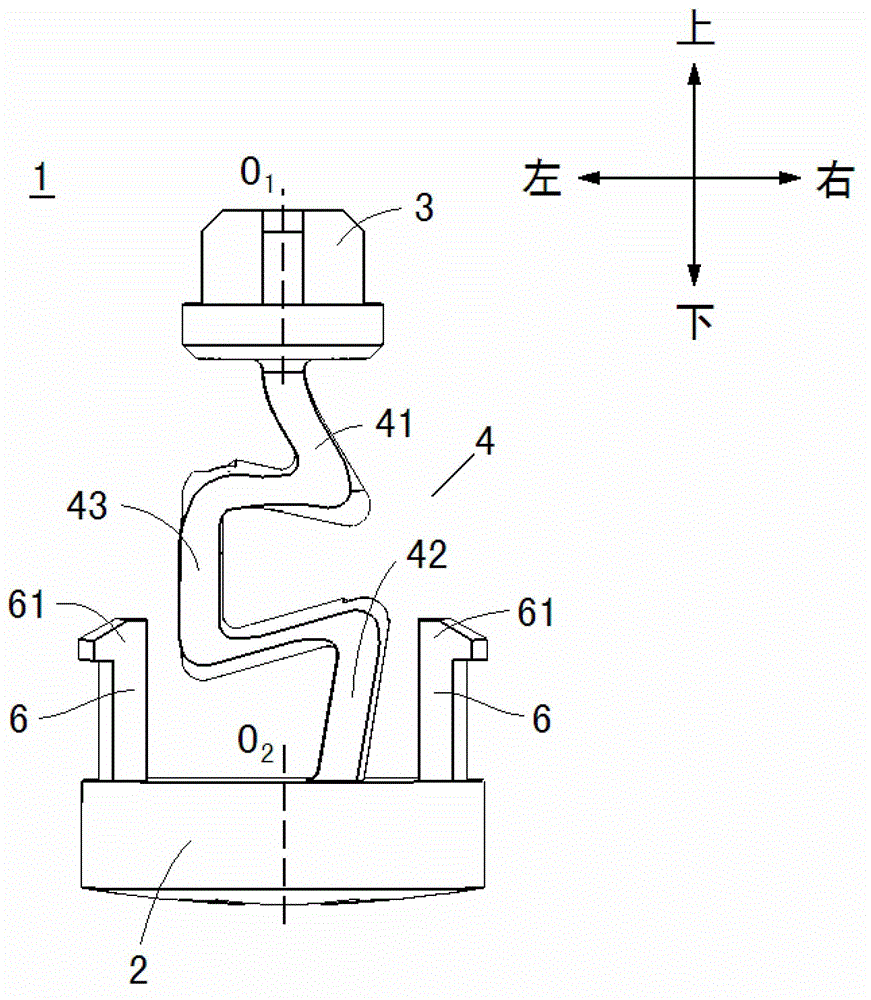

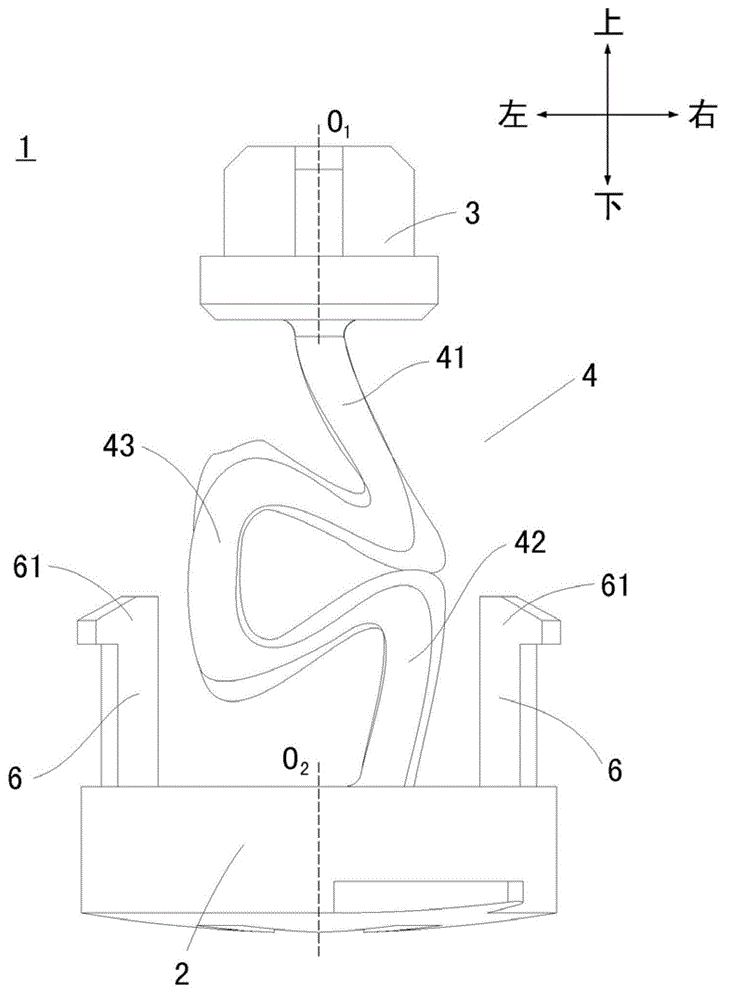

[0020] Below, refer to Figure 1-3 Embodiments of the present invention will be described.

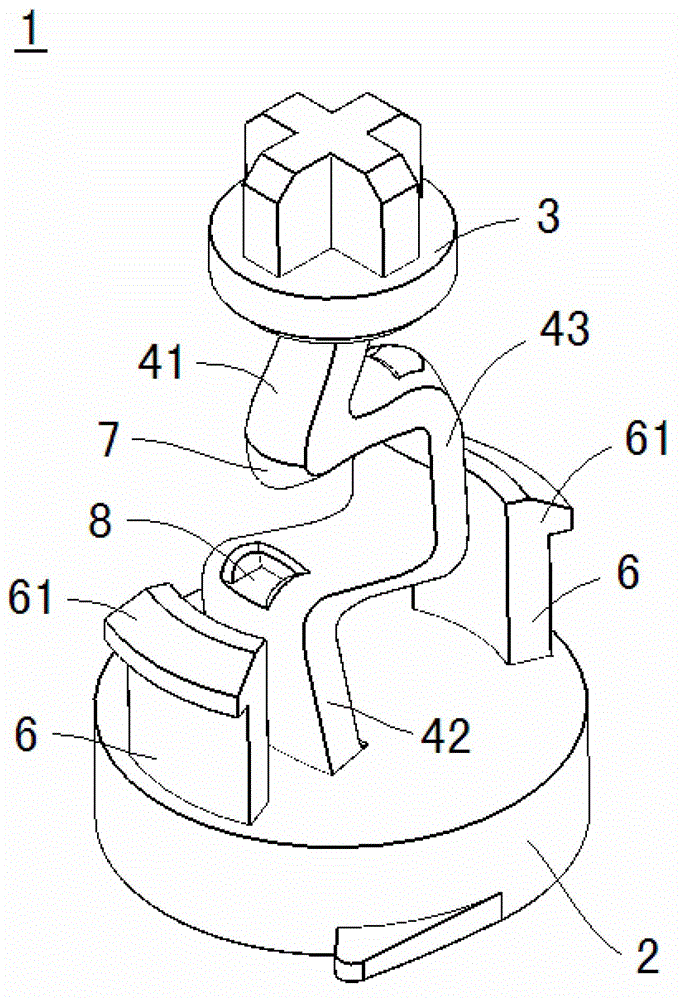

[0021] The knob of the present invention can be used to be installed on the panel of the electronic product. like figure 1 , figure 2 as well as image 3 As shown, the knob 1 has: an operating part 2 at the lower part, an engaging part 3 at the upper part, and a connecting part 4 between the operating part 2 and the engaging part 3 for connecting the operating part 2 and the engaging part 3 .

[0022] The operation member 2 is exposed to the outside of the panel when the knob 1 is attached to the panel. A cross-shaped groove is formed on the surface of the operation part 2 exposed to the outside of the panel, and an operator can insert a tool such as a screwdriver into the groove to rotate the knob 1 . Two locking portions 6 , 6 are formed on the peripheral portion of the upper side of the operation member 2 . The two buckle parts 6 , 6 are arranged opposite to the axis O2 of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com