Square tube sealing connector

A connector and tube sealing technology, applied in the direction of electrical components, etc., can solve the problems of increasing safety hazards, increasing the difficulty of on-site construction, increasing investment, etc., and achieves the effect of excellent expansion and contraction performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

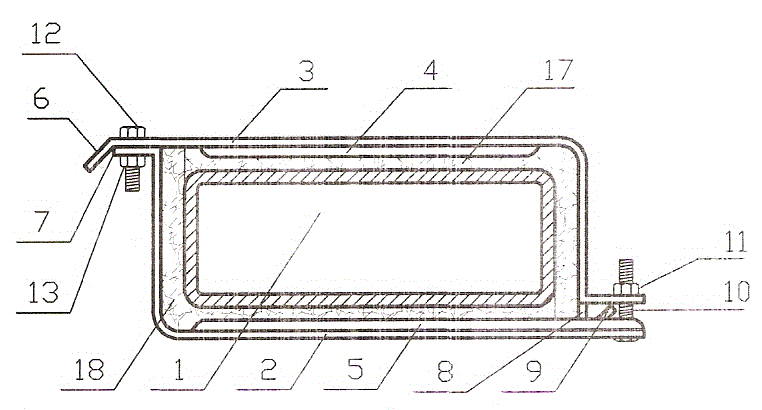

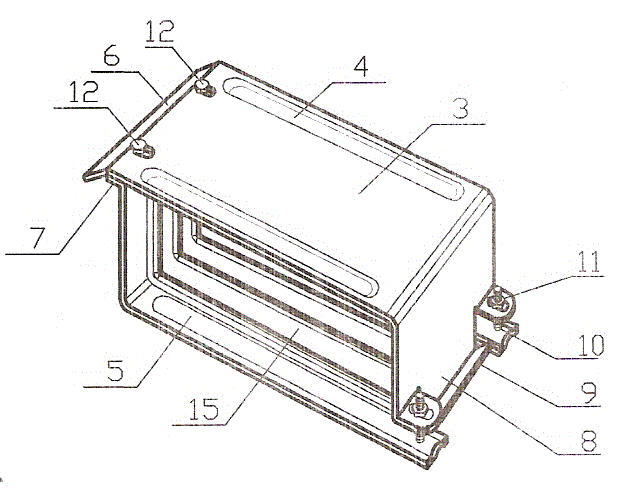

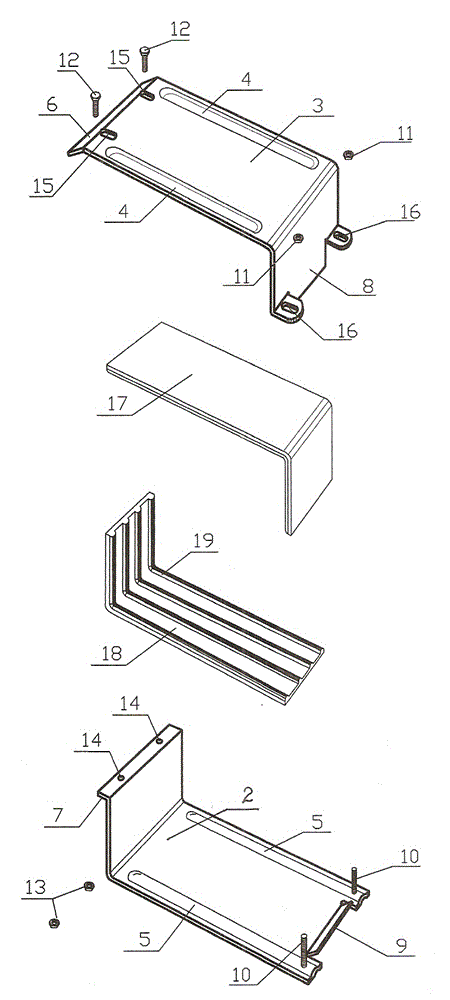

[0017] A square tube sealing connector, comprising an upper connecting piece 3 and a lower connecting piece 2. The upper connecting piece includes an upper piece and a side piece perpendicular to the upper piece. One end of the upper piece is in the form of a slope surface 6, and the slope surface is installed near the The waist-shaped hole 15 of the upper tightening bolt 12, the lower end of the side piece perpendicular to the upper piece is in the form of a sliding plate 8. The sliding plate 8 is provided with a waist-shaped hole 16 for installing the lower tightening bolt 10 on the proximal side; the lower connecting piece includes the lower piece and The vertical side piece of the lower piece, one end of the lower piece is in the form of a slope surface 9, a lower tightening bolt (or stud) 10 is arranged near the slope surface, and the upper end of the side piece perpendicular to the lower piece is in the form of a slide plate 7, which is close to the slide plate 7. A hole 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com