Stirring and filtering system for capsule reagent preparation

A filtration system and reagent technology, applied in filtration and separation, mixer accessories, fixed filter element filters, etc., to achieve the effect of avoiding emission, ensuring health, and effectively sealing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

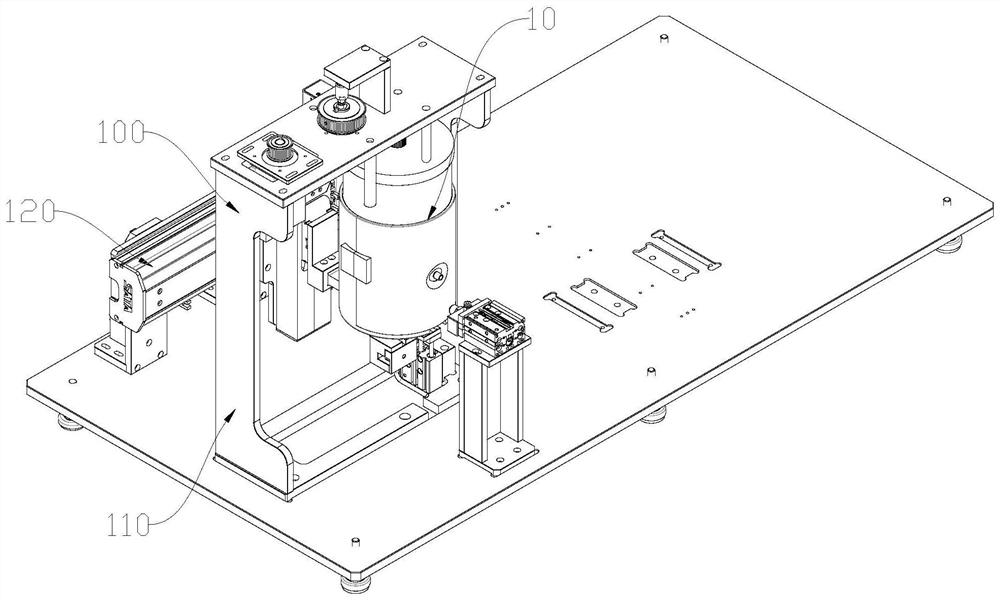

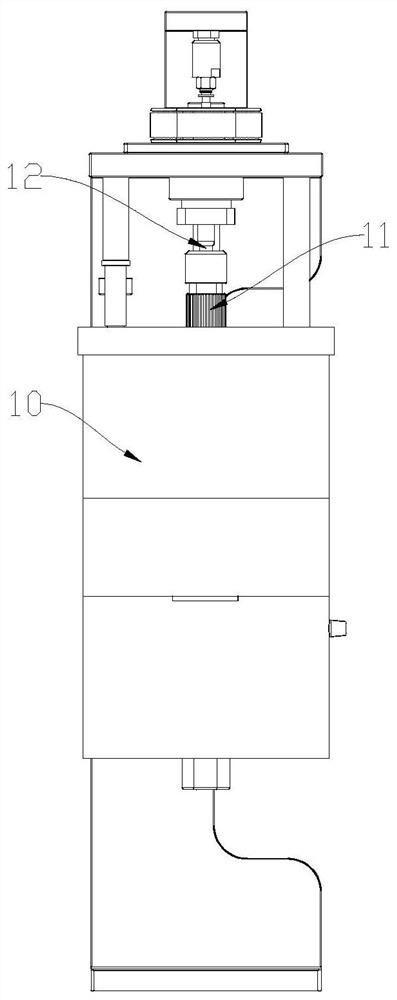

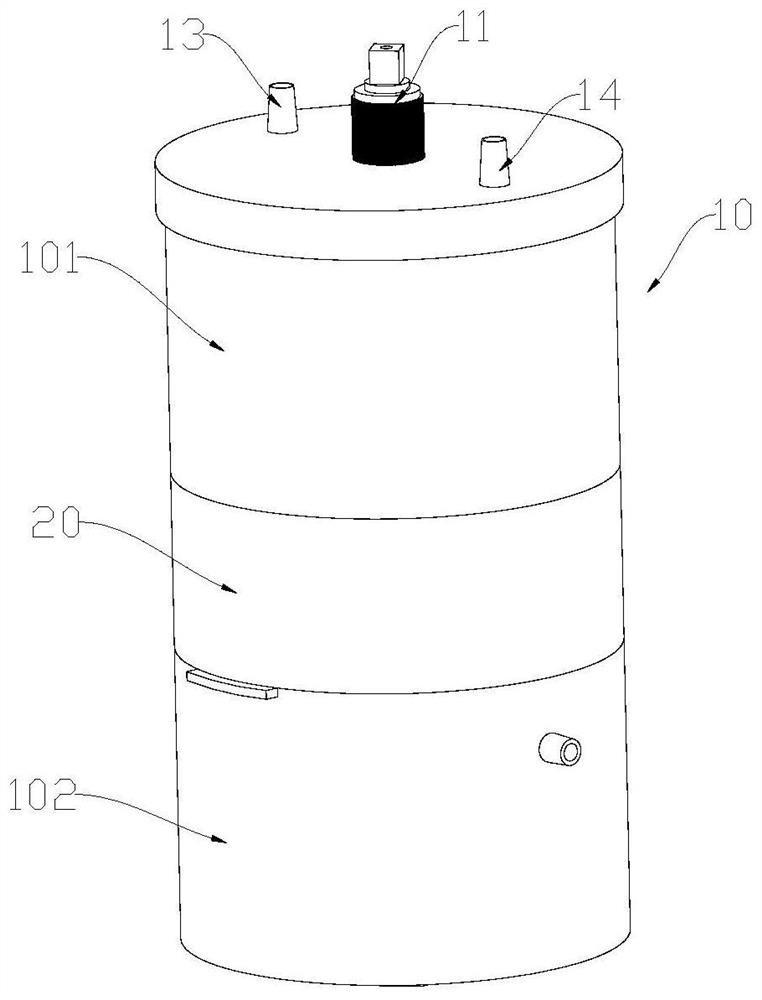

[0033] Such as figure 1 As shown, it is a schematic structural diagram of a stirring and filtering system made of a capsule reagent in a preferred embodiment of the present invention. The stirring system of this embodiment includes an installation assembly 100 and an agitation filter barrel 10 installed on the installation assembly 100; The filter barrel 10 is composed of a mixing barrel 101, a filter assembly 20, and a medicament barrel 102; the mixing barrel 101, the filter assembly 20, and the medicament barrel 102 are assembled together by threads, and the center of the bottom of the mixing barrel 101 is provided with a rubber pad 21;

[0034] In this embodiment, the installation assembly 100 includes a fixed frame 110 and a three-axis electric cylinder 120 arranged on the rear side of the fixed frame 110; the three-axis electric cylinder 120 is connected to the stirring filter barrel 10 and can drive the stirring filter barrel 10 moves up and down, and the stirring connec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com