Nozzle-adaptive liquid quantitative pour-out device

An adaptable, bottle mouth technology, applied in the direction of dispensing devices, caps with auxiliary devices, sealing parts with auxiliary devices, etc., can solve problems such as environmental pollution, difficult industrial production, chicken ribs, etc., to reduce costs and avoid Waste of resources and environmental pollution, the effect of ease of use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

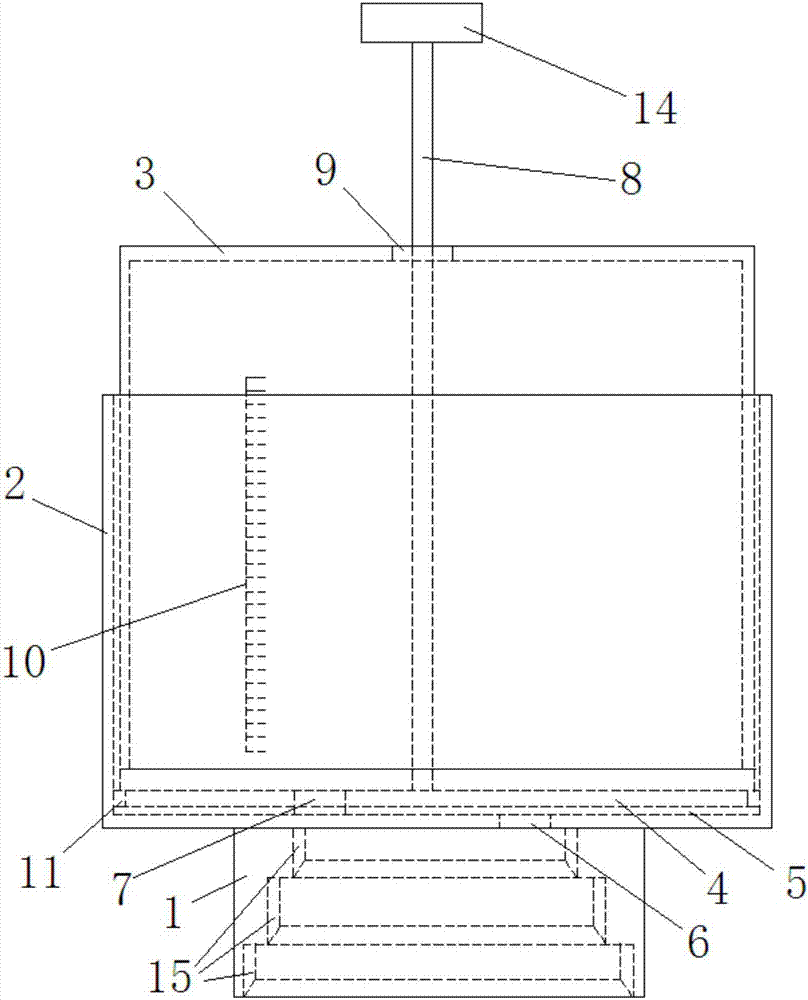

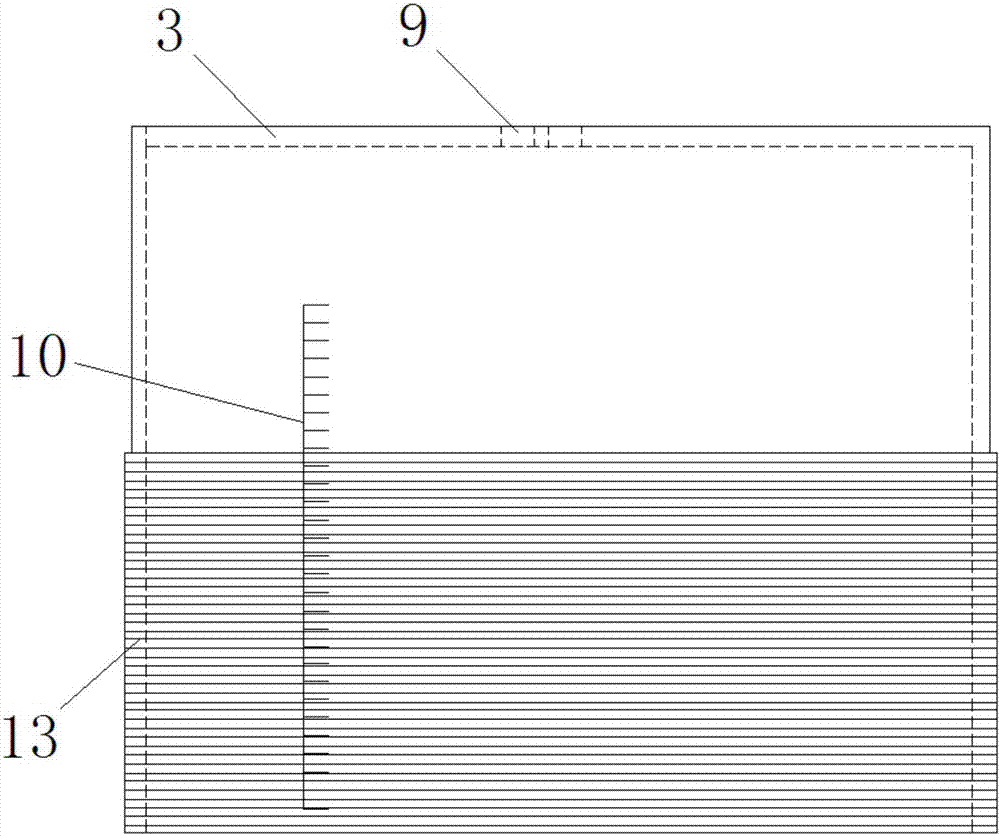

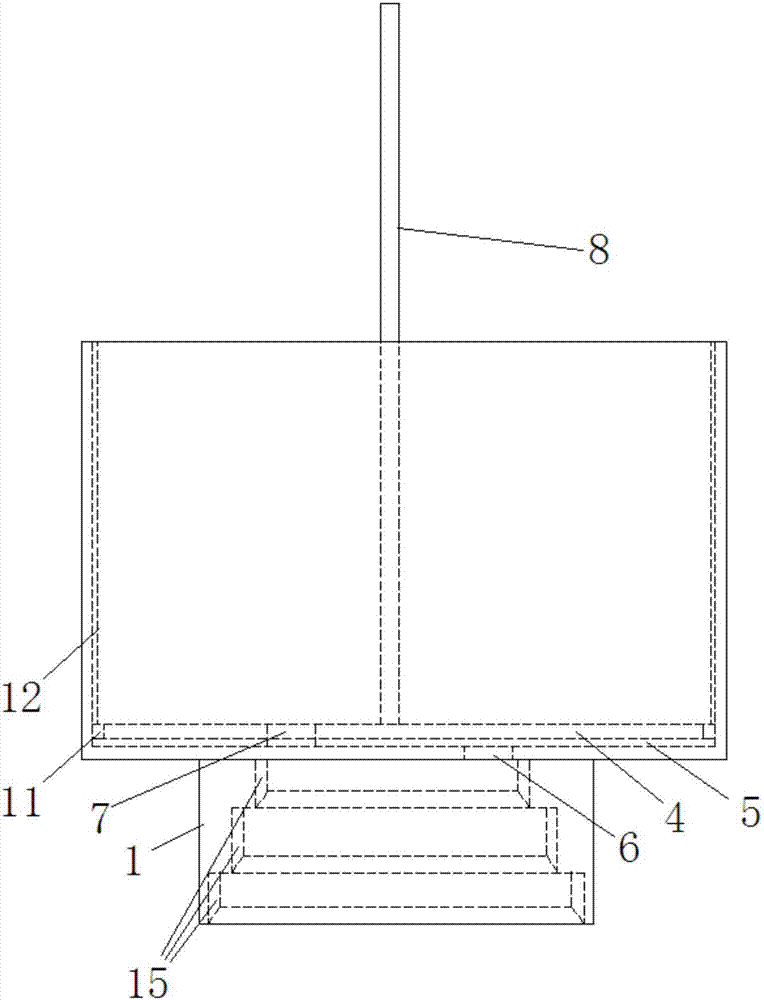

[0023] refer to Figure 1 to Figure 9 , the present embodiment provides a bottle mouth adaptable liquid quantitative pouring device, including a bottle mouth connection cap 1, a measuring cylinder 2 and an adjusting cylinder 3, the top opening of the measuring cylinder 2, the opening at the bottom of the adjusting cylinder 3, the measuring cylinder 2 and the adjusting cylinder 3 are cylindrical structures, the inner wall of the measuring cylinder 2 is provided with an internal thread 12, the outer wall of the adjusting cylinder 3 is provided with an external thread 13 matching the internal thread 12, and the lower end of the adjusting cylinder 3 is screwed into the measuring cylinder 2 , and the sealing between the measuring cylinder 2 and the adjusting cylinder 3 is arranged, the bottle mouth connecting cap 1 is a bottle cap-like structure, and the inner side of the bottle mouth connecting cap 1 is a stepped structure with the inner diameter gradually decreasing from bottom to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com