Brewing device for extracting a portion capsule, method for operating a brewing device and use of a brewing device

A dispensing box and brewing technology, which is applied in applications, beverage preparation devices, household appliances, etc., and can solve problems such as damage to the brewing device

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

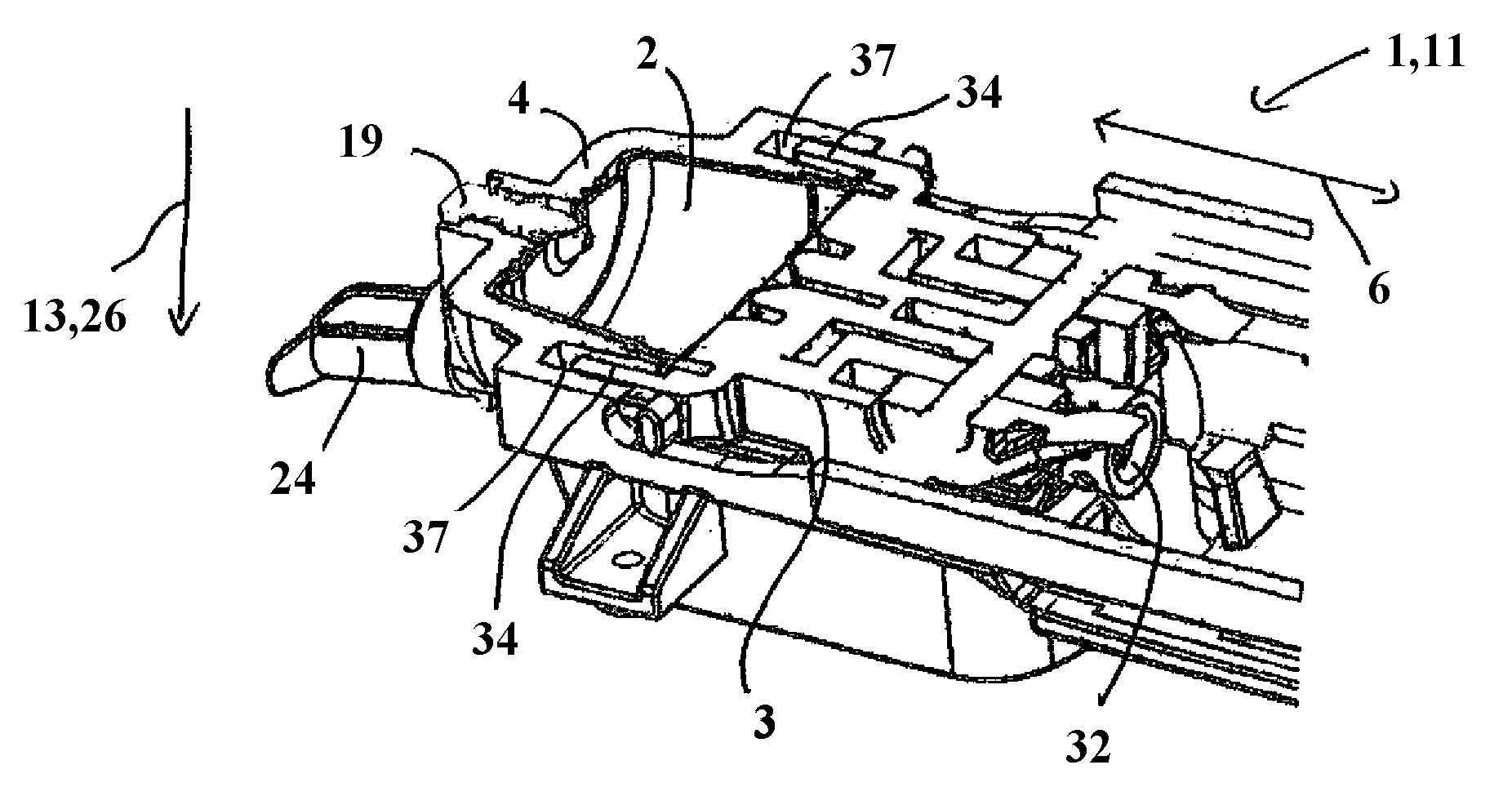

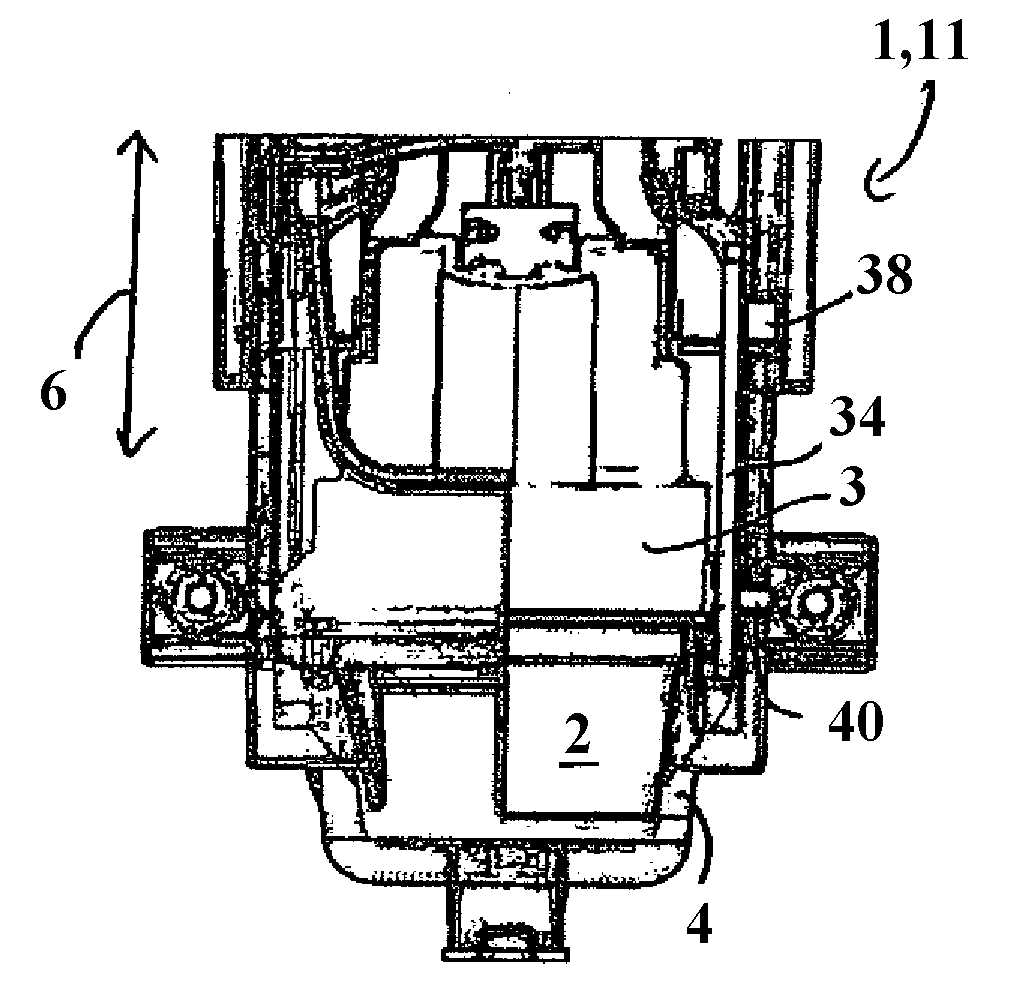

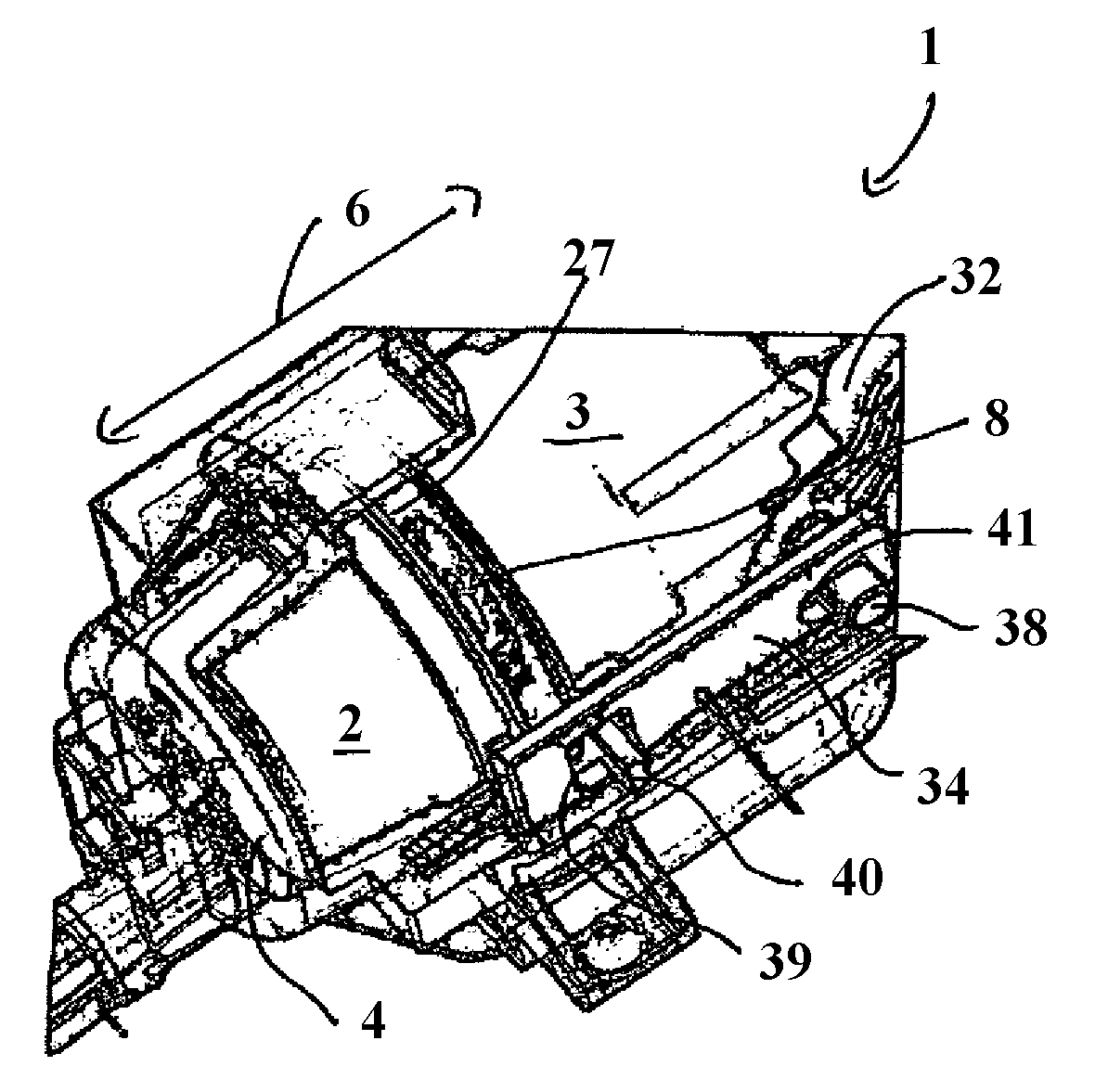

[0039] 1 a to 1 k show schematic sectional views of a brewing device 1 for extracting portion capsules 2 according to a first embodiment of the invention. The brewing device 1 here comprises a first brewing chamber element 3 configured as a receiving element or a partially hollow bell element 21 and a second brewing chamber element 4 configured as a closing element 30 or piston. The first brewing chamber element 3 is movable relative to the second brewing chamber element 4 along the axial direction 6 between a loading position 17 illustrated in FIGS. 1a to 1k and an extraction position 11 illustrated in FIG. 1f.

[0040] The dispensing box 2 includes a truncated cone 31 made of plastic and configured in the shape of a pot. The truncated cone 31 is closed gas-tight by means of a lid 25 made of plastic or aluminum film. The beverage substance, in particular roast coffee powder, which can be extracted by means of an extraction liquid, is present in the dispensing cartridge 2 . ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com