Spring-loaded pressure relief device

A technology of releasing device and pressure, applied in the field of pressure releasing device, which can solve the problems of secondary damage in the discharge area, uneven distribution of discharge materials, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

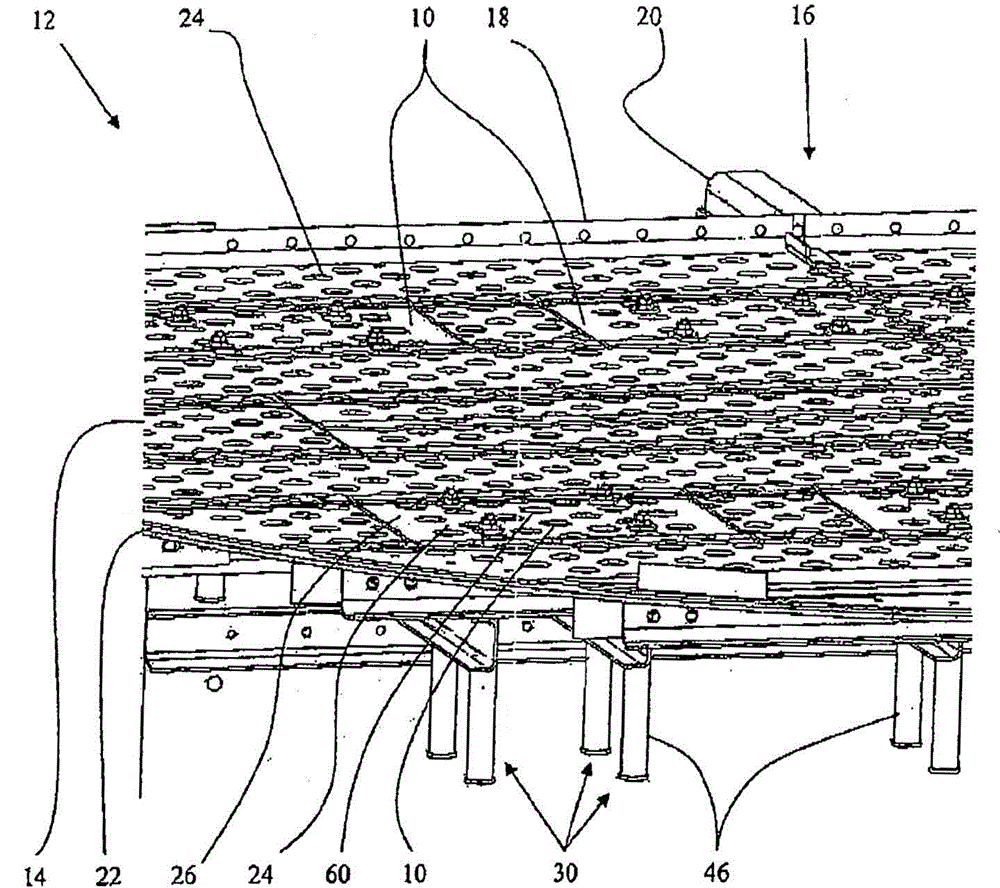

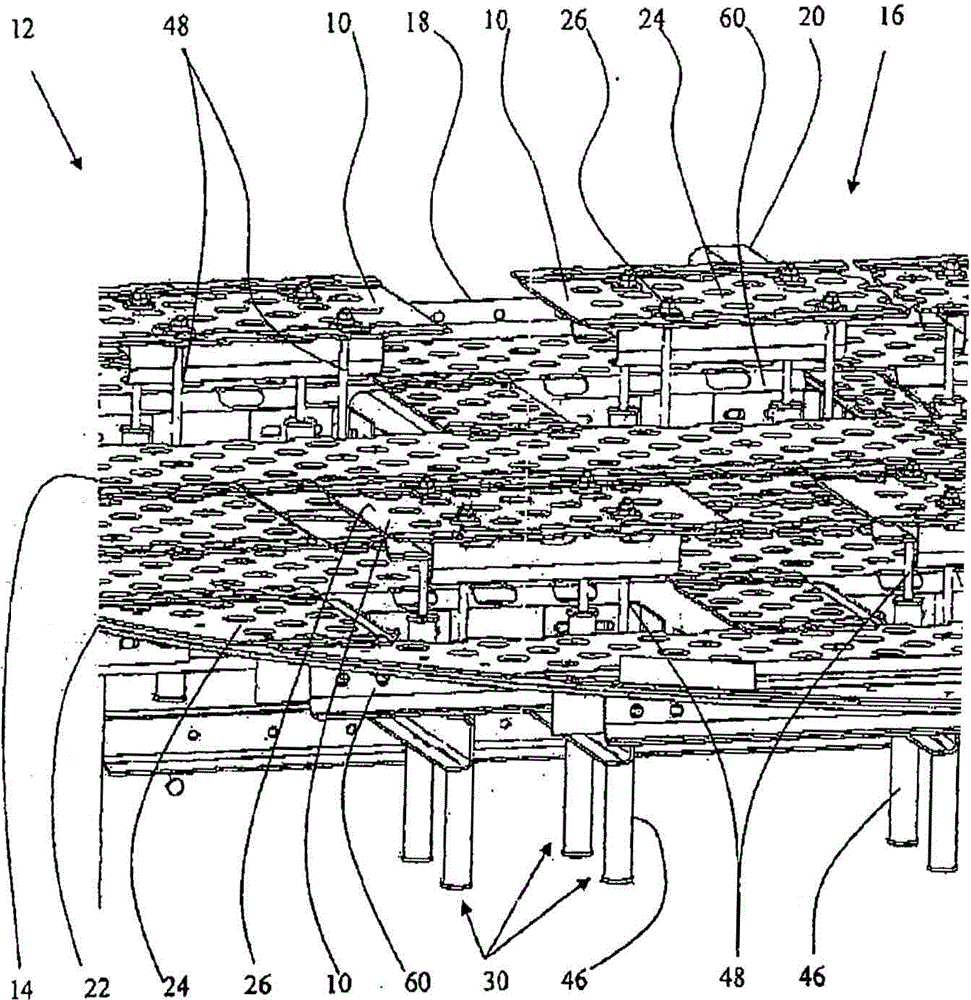

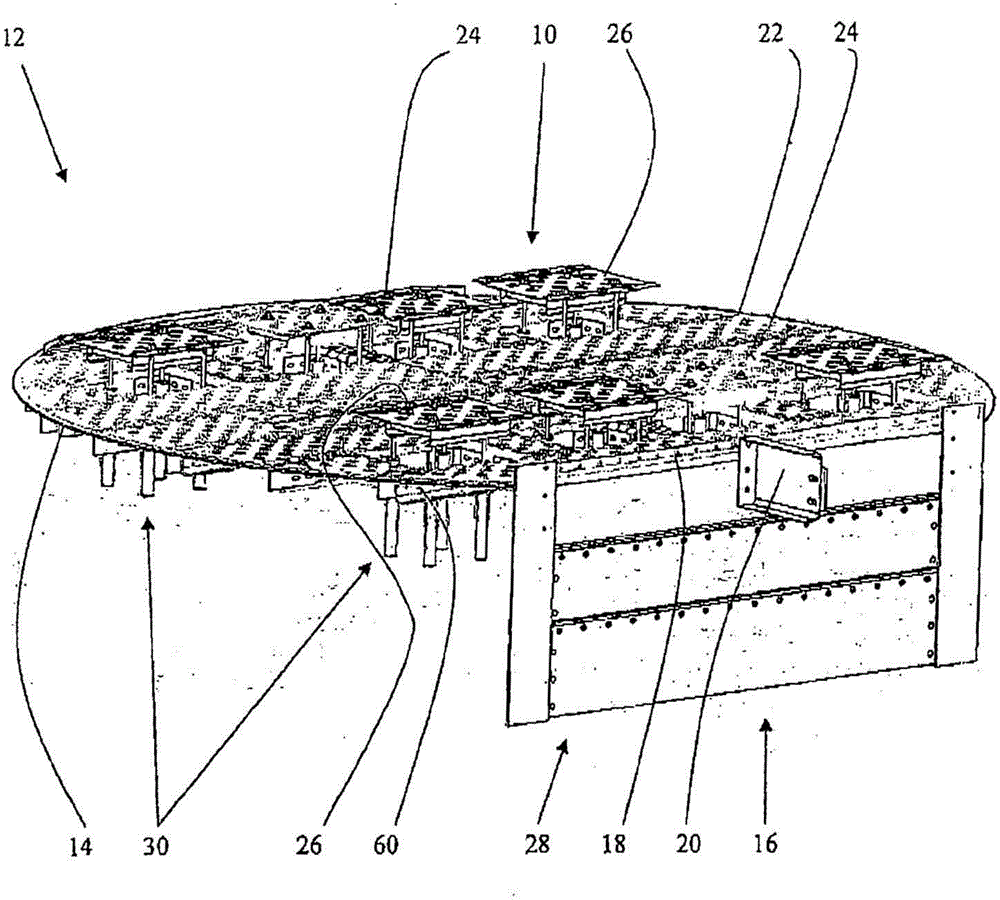

[0022] refer to Figure 1-3 , a tray assembly 12 for vapor / liquid contact is installed in a distillation column with side walls (not shown). The outer edges of the tray assembly 12 are attached to the side walls. Tray 12 has a deck 14 which may comprise one or more sections and at least one downcomer 16 . The deck 14 has perforations 24 through which vapors can rise. Those skilled in the art will appreciate that the perforations 24 may be simple holes or include valves, blisters or other devices to control and distribute the vapor rising through the perforations 24 . Typically, tray 12 has an outlet weir 18 to maintain liquid and froth depth above deck 14 . Additional structural components may also be included to maintain the integrity and position of the trays 12 within the distillation column, for example, structural components 20 ( Figure 1-Figure 3 ) extends through the downcomer 16, from the tray 12 above the downcomer wall 28 to the inner surface of the column wall....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com