Intelligent robot automatic assembling device

A technology of automatic assembly devices and intelligent robots, which is applied in auxiliary devices, comprehensive factory control, auxiliary welding equipment, etc., to achieve the effects of improving stability, improving assembly efficiency, and improving assembly efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

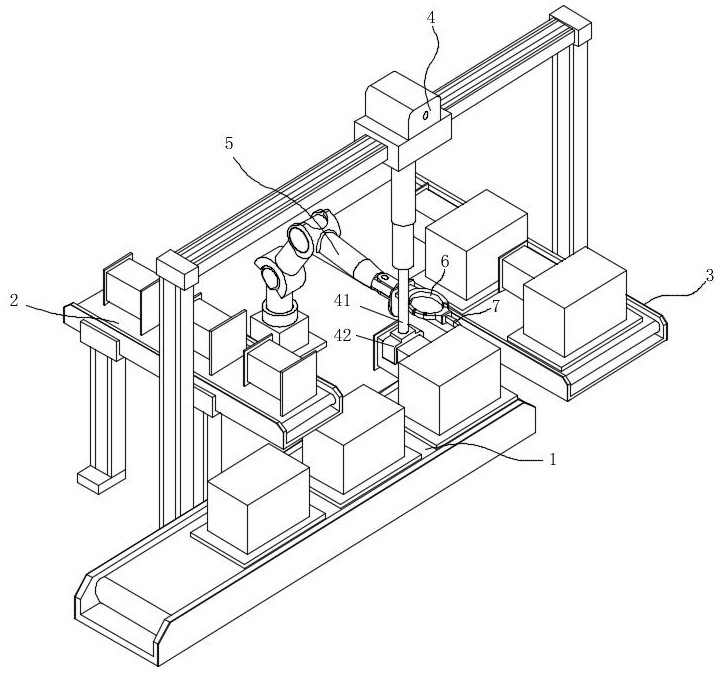

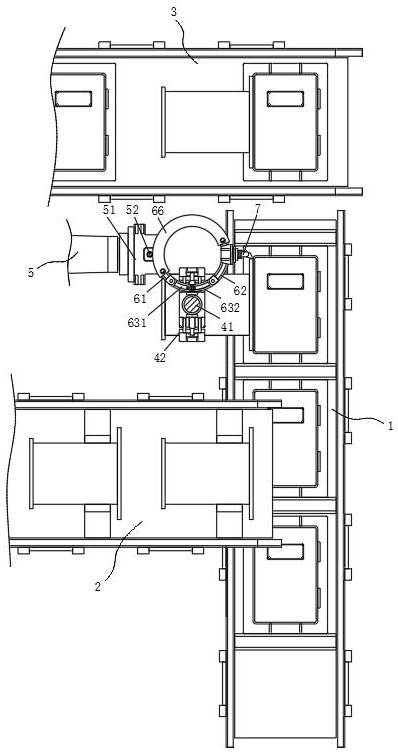

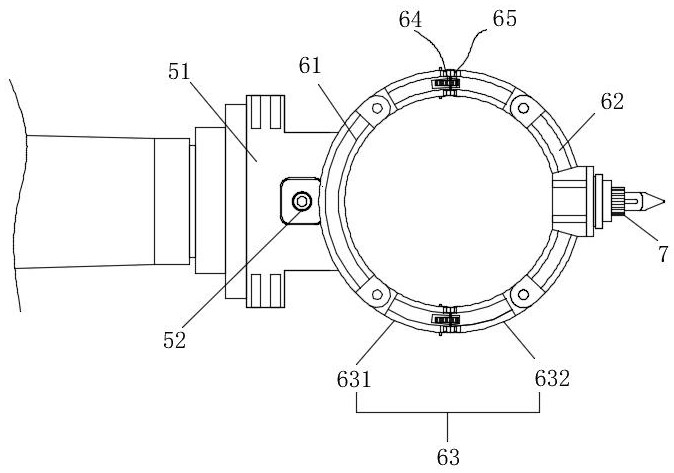

[0044] Refer to the manual attached figure 1 and attached figure 2 , an intelligent robot automatic assembly device, comprising a first conveying assembly 1, a second conveying assembly 2 and an output assembly 3, such as figure 1 As shown, the first conveying assembly 1, the second conveying assembly 2 and the output assembly 3 all adopt a belt conveying structure, which consists of a conveying frame, a conveying belt, a drive shaft roller and a drive motor, and the second conveying assembly 2 is provided with a pair of A positioning tool for positioning and supporting the two workpieces, so that the device can be better integrated into the production line. The first conveying assembly 1 is used for conveying the first workpiece to be assembled. The first workpiece is a larger workpiece and can be stably placed on a flat surface Or the workpiece that can be placed on the conveying device smoothly, the conveying end of the first conveying assembly 1 is set as the assembly st...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com