Nickel oxide doped sodium titanate-titanium dioxide composite photocatalyst and preparation method thereof

A technology of titanium dioxide and sodium titanate, which is applied in the field of composite photocatalyst preparation, can solve the problems of reducing TiO2 photocatalytic activity, adsorption and utilization, and catalyst specific surface area reduction, so as to increase catalytic active sites and uniform size , the effect of improving photocatalytic efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] A. Cut the nickel foam into different sizes and shapes as required, ultrasonically wash with absolute ethanol and deionized water to remove surface impurities, and dry. In the air, the temperature was raised to 550°C at a rate of 5°C / min for 10 minutes of pre-oxidation treatment.

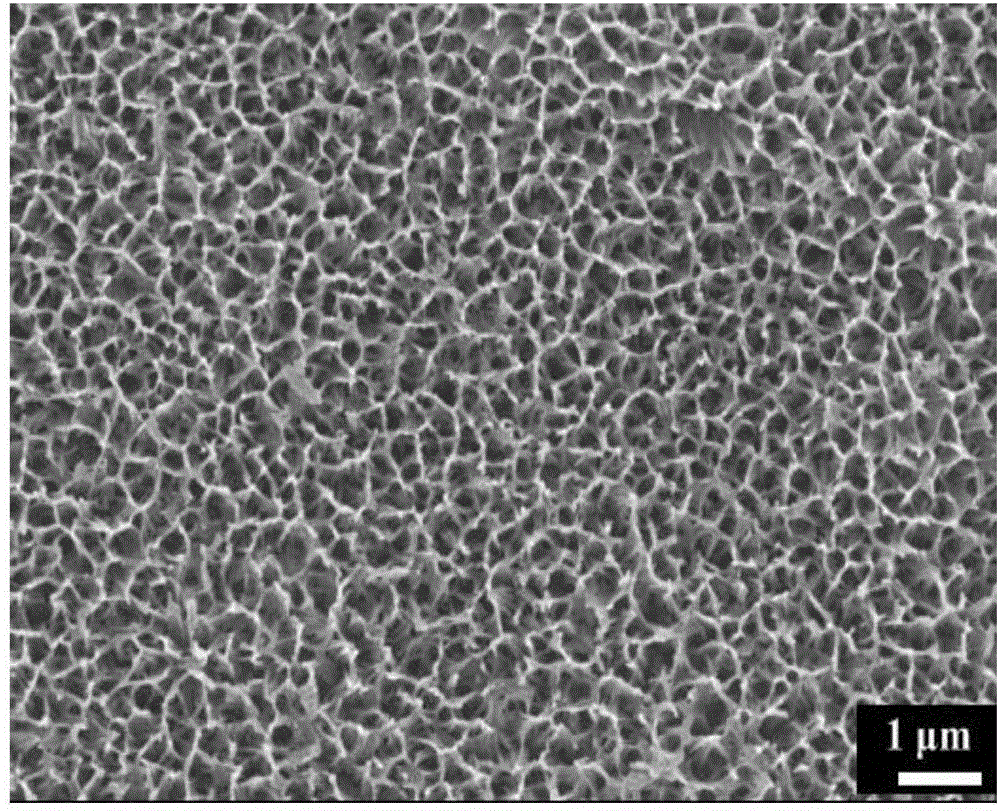

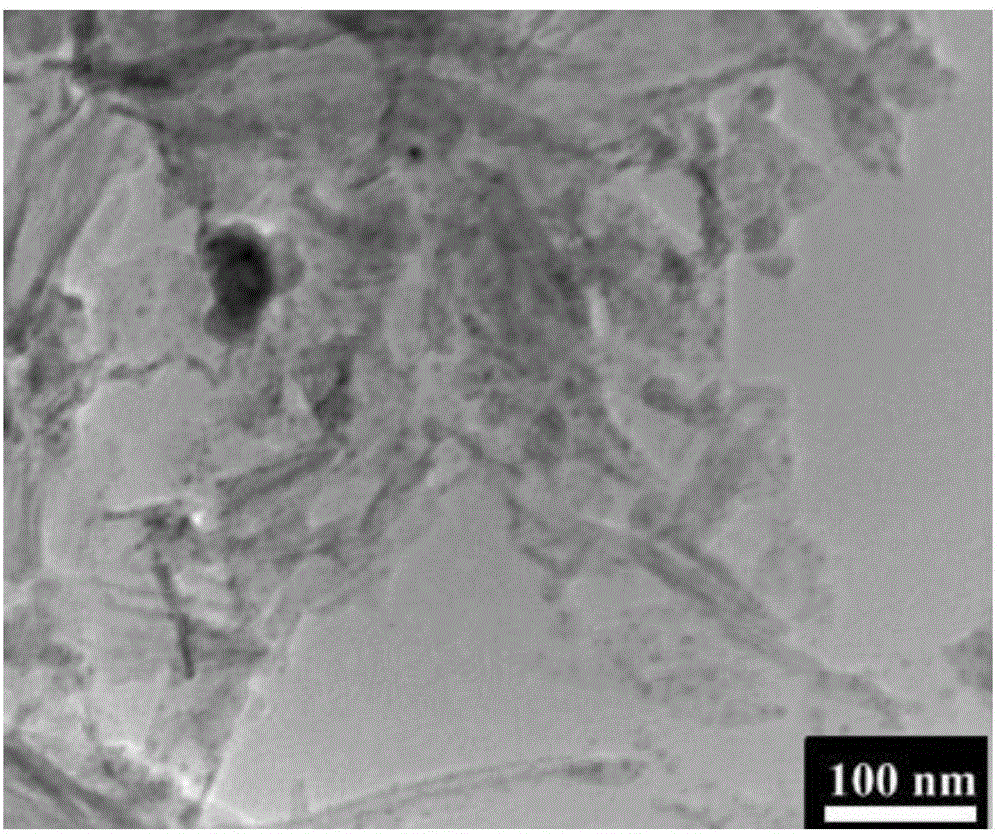

[0027] B. Add 20mL of ethanol, 10mL of acetic acid, and 2mL of tetrabutyl titanate into the reaction kettle, stir evenly, put in the nickel foam treated in step A, and seal it. The reaction kettle was heated at 120°C for 10h, cooled down naturally, and then dried. Then, it was calcined at 550° C. for 45 minutes at a heating rate of 2° C. / min in an air atmosphere to obtain a foamed nickel-supported titania nano-film.

[0028] C. Prepare a 10 mol / L sodium hydroxide solution, put the foamed nickel-supported titanium dioxide nano-film sample obtained in step B, and heat at 100° C. for 9 hours. After the reactor was cooled down naturally, it was taken out, washed with deionized water, and dried...

Embodiment 2

[0030] A. Cut the nickel foam into different sizes and shapes as required, ultrasonically wash with absolute ethanol and deionized water to remove surface impurities, and dry. In the air, the temperature was raised to 550°C at a rate of 5°C / min for 10 minutes of pre-oxidation treatment.

[0031] B. Add 20mL of ethanol, 10mL of acetic acid, and 2mL of tetrabutyl titanate into the reaction kettle, stir evenly, put in the nickel foam treated in step A, and seal it. The reaction kettle was heated at 120°C for 10h, cooled down naturally, and then dried. Then, it was calcined at 550° C. for 45 minutes at a heating rate of 2° C. / min in an air atmosphere to obtain a foamed nickel-supported titania nano-film.

[0032] C. Prepare a 10 mol / L sodium hydroxide solution, put the foamed nickel-supported titanium dioxide nano-film sample obtained in step B, and heat at 160° C. for 9 hours. After the reactor was cooled down naturally, it was taken out, washed with deionized water, and dried...

Embodiment 3

[0034] A. Cut the nickel foam into different sizes and shapes as required, ultrasonically wash with absolute ethanol and deionized water to remove surface impurities, and dry. Pre-oxidation treatment was performed in air at a heating rate of 5°C / min to 400°C for 10 minutes of calcination.

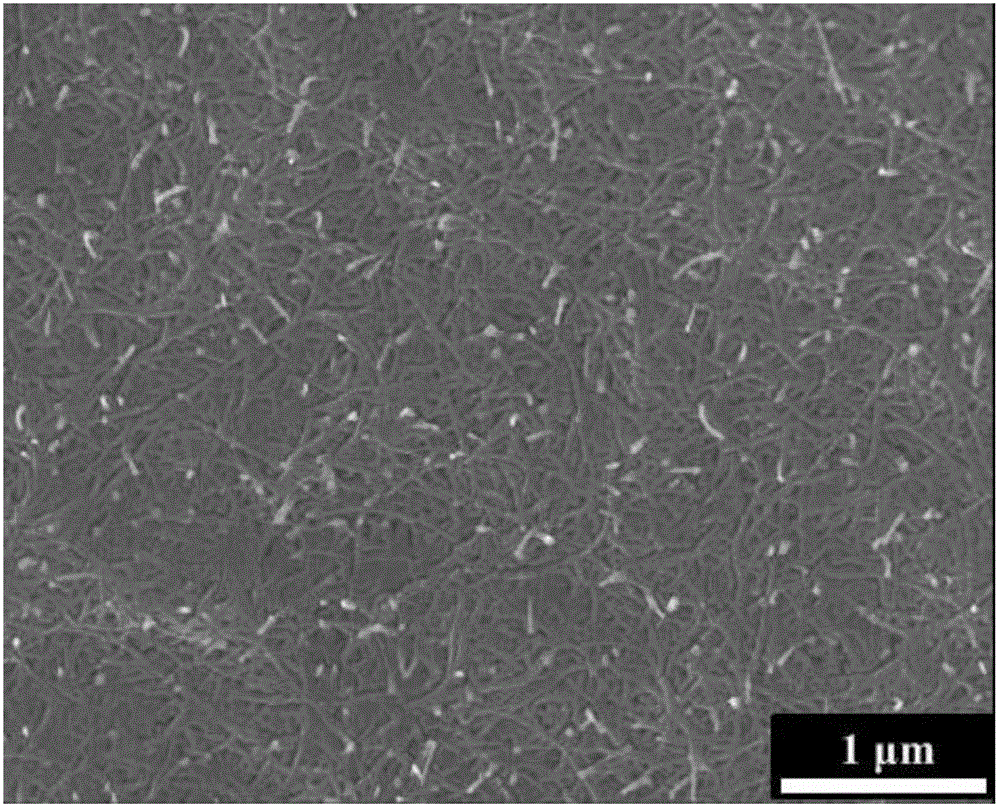

[0035] B. Add 16 mL of propanol, 8 mL of acetic acid, and 2 mL of tetrabutyl titanate into the reaction kettle, stir evenly, put in the nickel foam treated in step A, and seal it. The reaction kettle was heated at 100°C for 15h, cooled down naturally, and then dried. Then, it was calcined at 400° C. for 30 minutes at a heating rate of 2° C. / min in an air atmosphere to obtain a foamed nickel-supported titania nano-film.

[0036] C. Prepare a 5 mol / L sodium hydroxide solution, put the foamed nickel-supported titanium dioxide nano-film sample obtained in step B, and heat at 100° C. for 8 hours. After the reactor was cooled down naturally, it was taken out, washed with deionized water, and dri...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com