Quick plate collecting machine

A kind of unwinding machine, fast technology, applied in stacking receiving device, sending objects, thin material processing and other directions, can solve the problems of expensive unwinding machine, increased production cost, slow board unwinding speed, etc. Board for quick and easy-to-operate effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

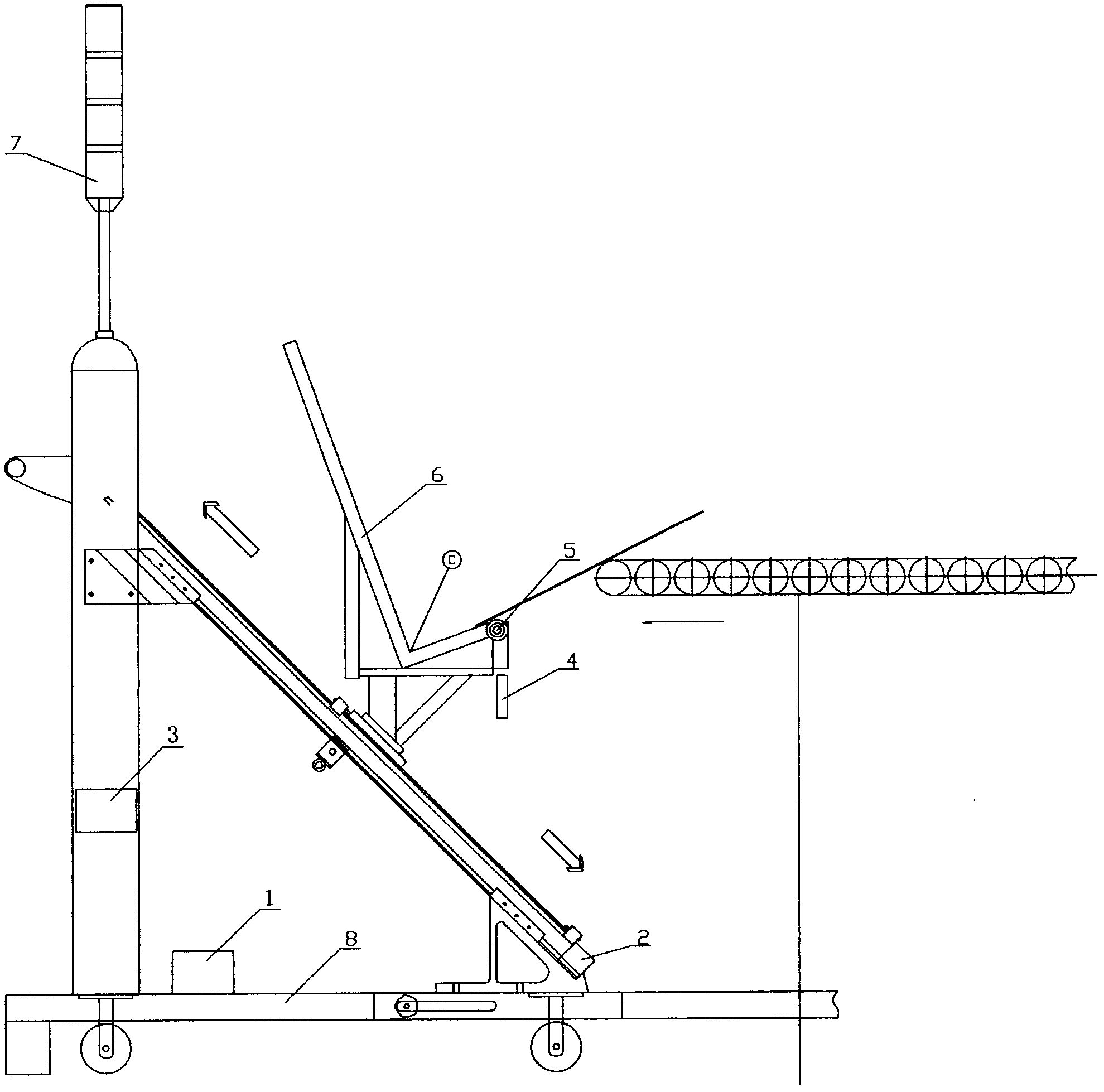

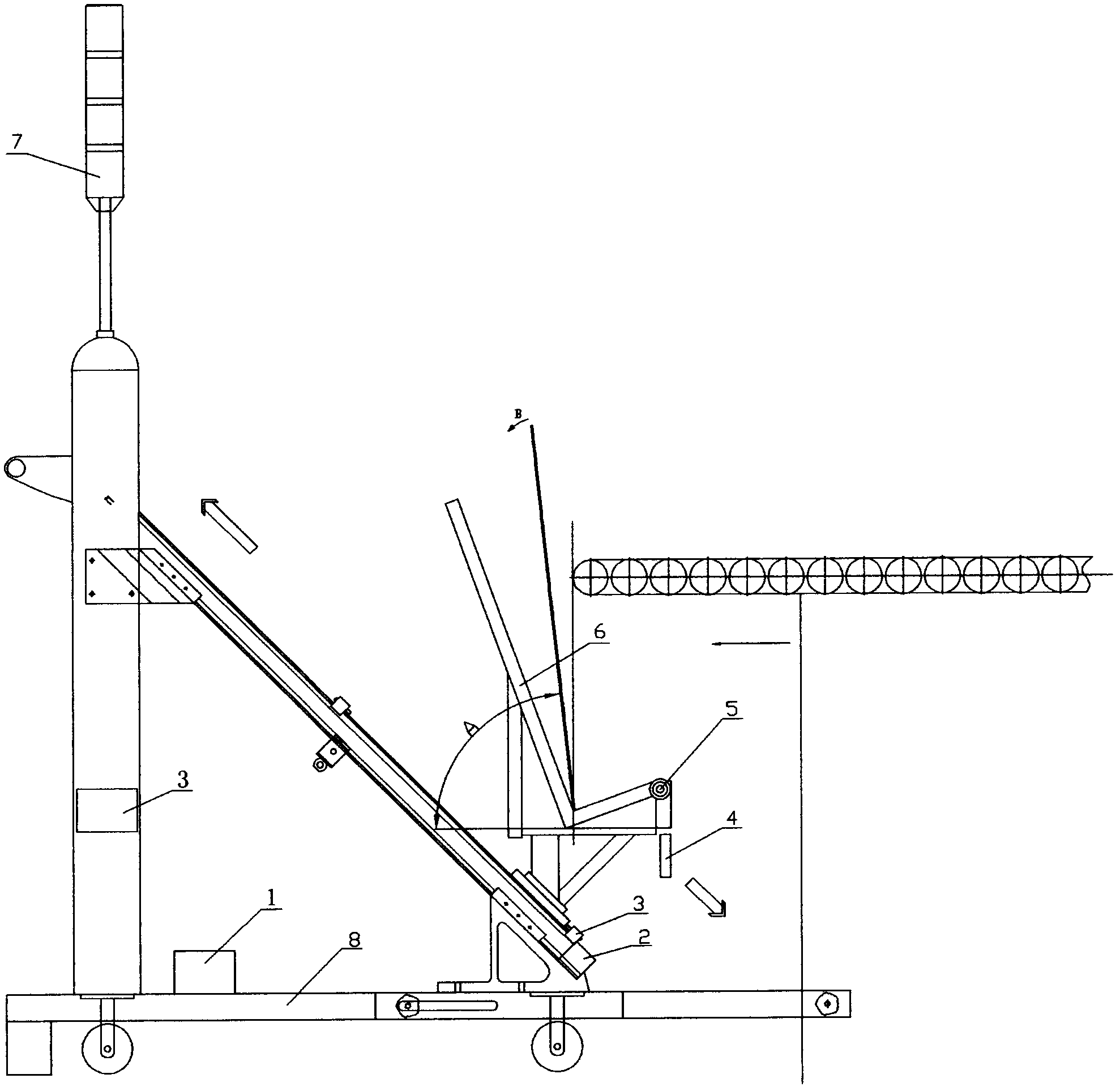

[0010] The fast board receiving machine of the present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

[0011] Such as figure 1 and figure 2 As shown, a fast board receiving machine includes a base frame 8, a board receiving rack 6, an induction control system and a shaftless cylinder 2 capable of driving the board receiving rack 6 to move up and down, and the board receiving rack 6 is fixed above the shaftless cylinder 2 , an indicator light 7 is arranged on the pedestal 8, the induction control system includes a contactor 4 capable of receiving signals, a relay 3 and a solenoid valve 1 for controlling air in and out, a roller 5 is arranged on the board receiving rack 6, and the contactor 4 is provided Below the roller 5, the relay 3 and the electromagnetic valve 1 are respectively fixed on the pedestal 8 below the indicator light 7, and the motion mechanism of the shaftless cylinder 2 is arranged on the upp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com