Carbon fiber tow layered conveying device

A carbon fiber tow and transmission device technology, which is applied in the directions of transportation and packaging, delivery of filamentous materials, thin material processing, etc. Fiber quality and other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0009] The present invention is further described below in conjunction with embodiment and accompanying drawing.

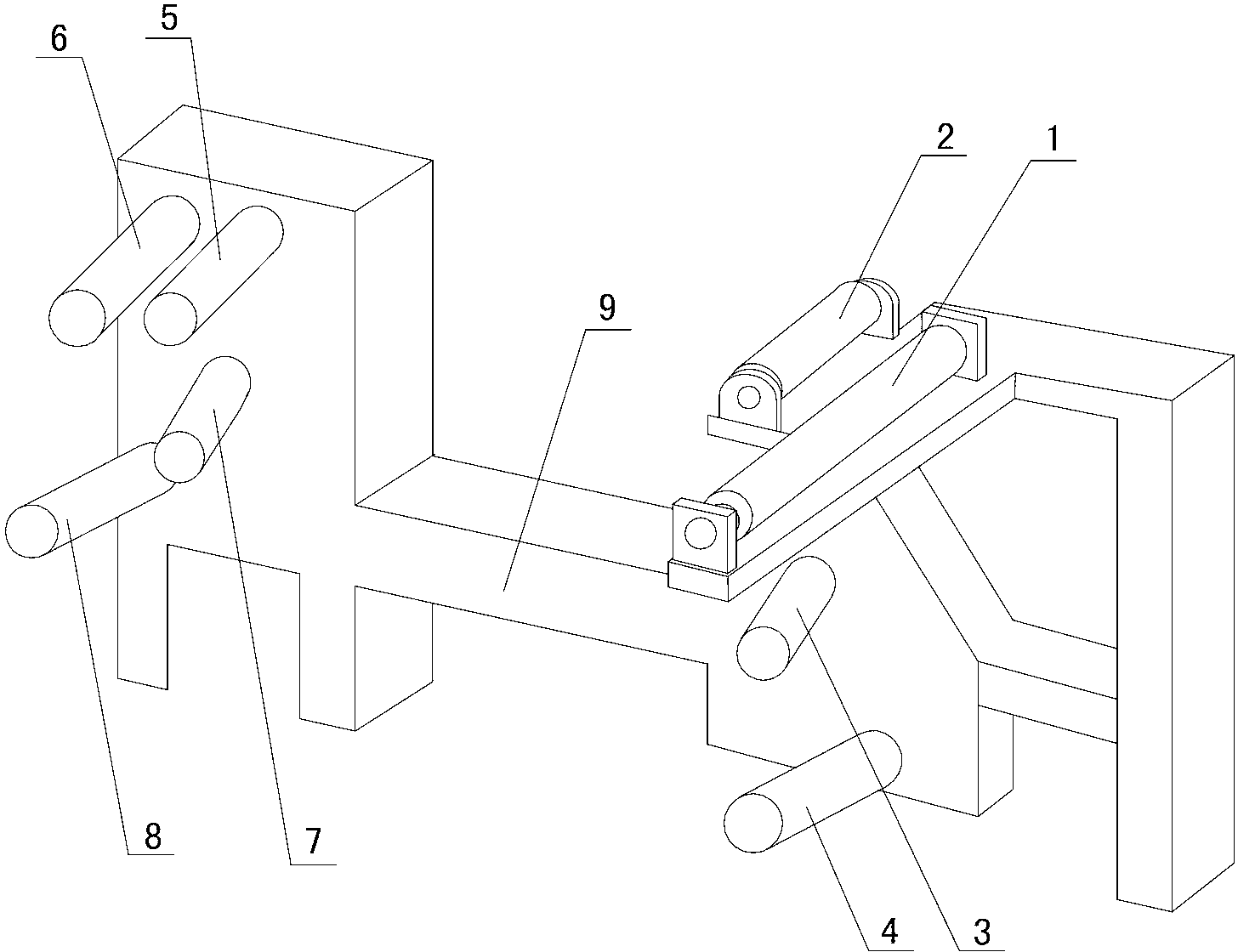

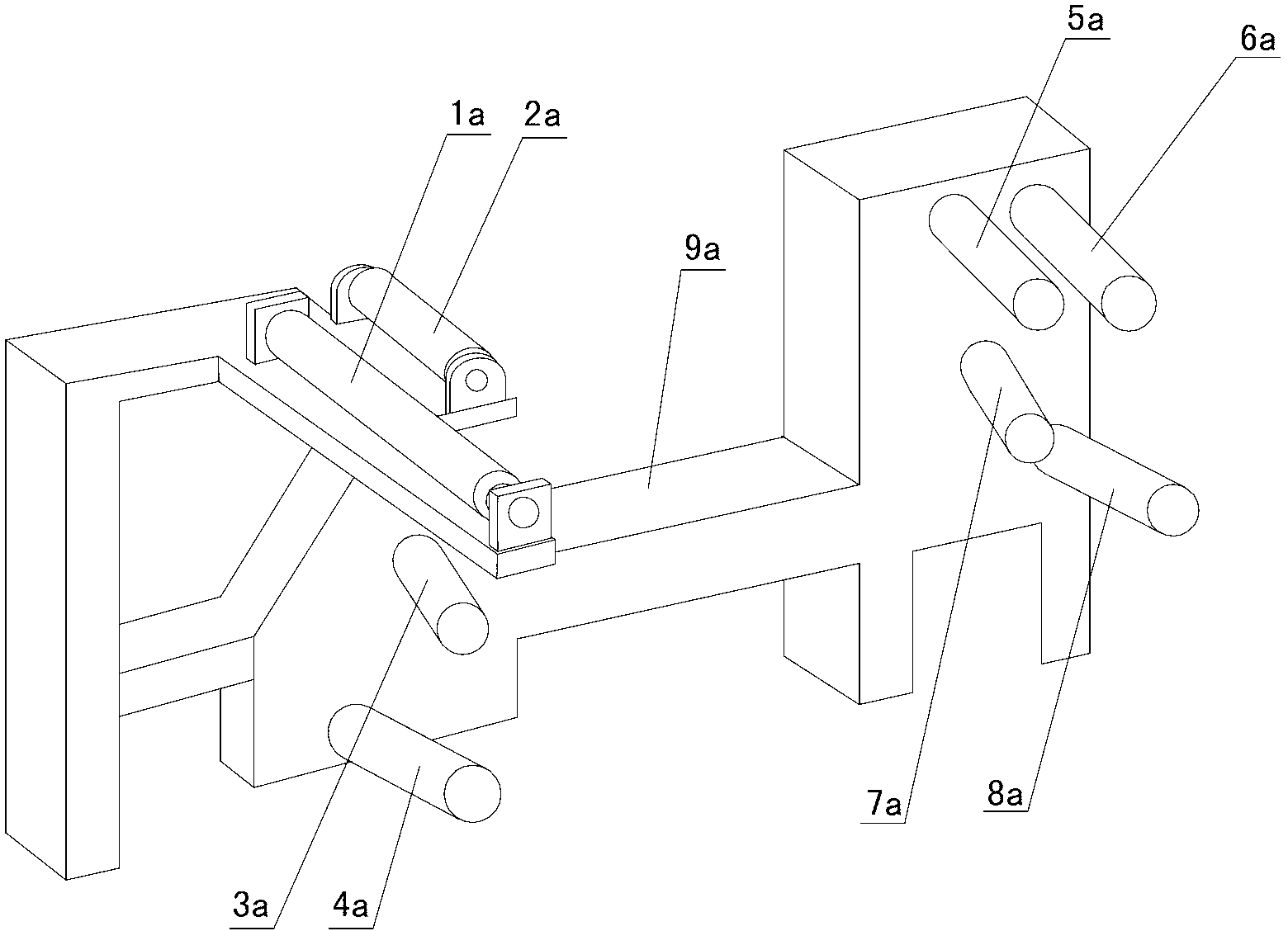

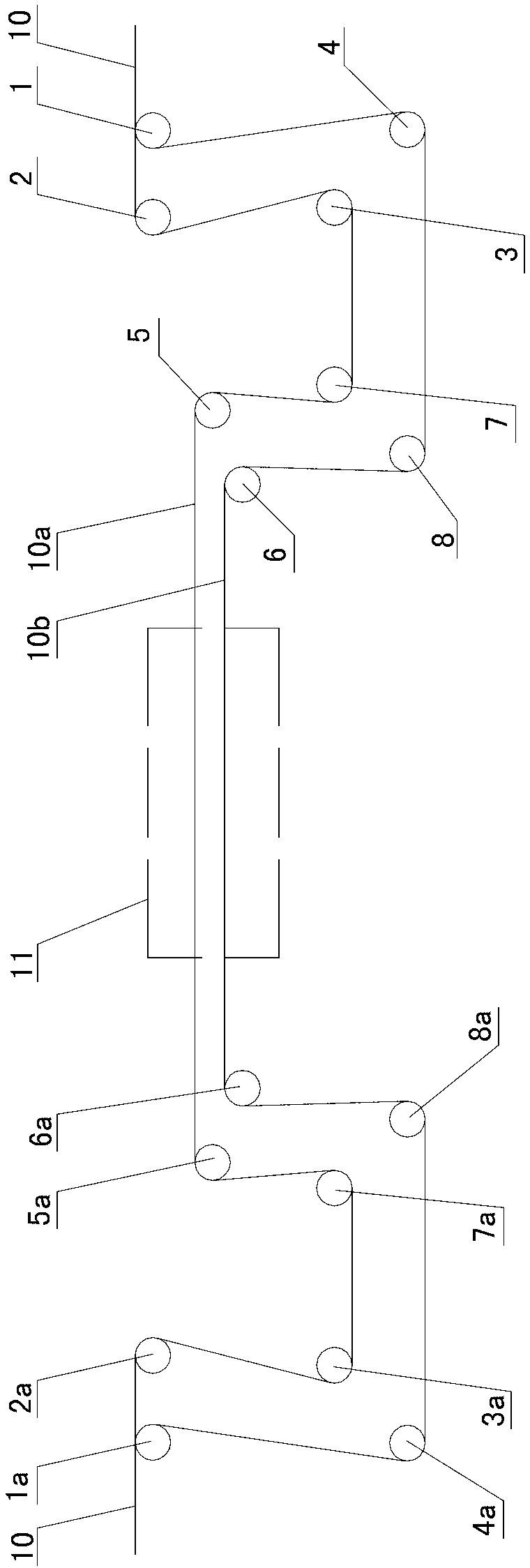

[0010] see figure 1

[0011] The tow narrowing device in the carbon fiber tow layered transmission device provided by the present invention has a frame 9, and a first rotating guide roller 1 and a second driving guide roller 2 parallel to each other are installed on the upper part of one side of the frame 9 , the two ends of the first rotating guide roller 1 and the second driving guide roller 2 are supported by bearing seats on the frame 1, the first rotating guide roller 1 is located outside the second rotating guide roller 2, and the length of the former is the latter Twice the length, on the frame 1, the first guide roller 3 is fixed below the second rotating guide roller 2, and the second guide roller 4 is fixed on the frame below the first guide roller 3, and on the other side of the frame The upper part of the side is fixed with the first support roller 5...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com