Virtual prototype disassembly sequence planning method

A technology of sequence planning and virtual prototyping, applied in special data processing applications, instruments, electrical digital data processing, etc., can solve problems such as different disassembly tasks, improve accuracy and safety, optimize disassembly sequences, and reduce maintenance training costs Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

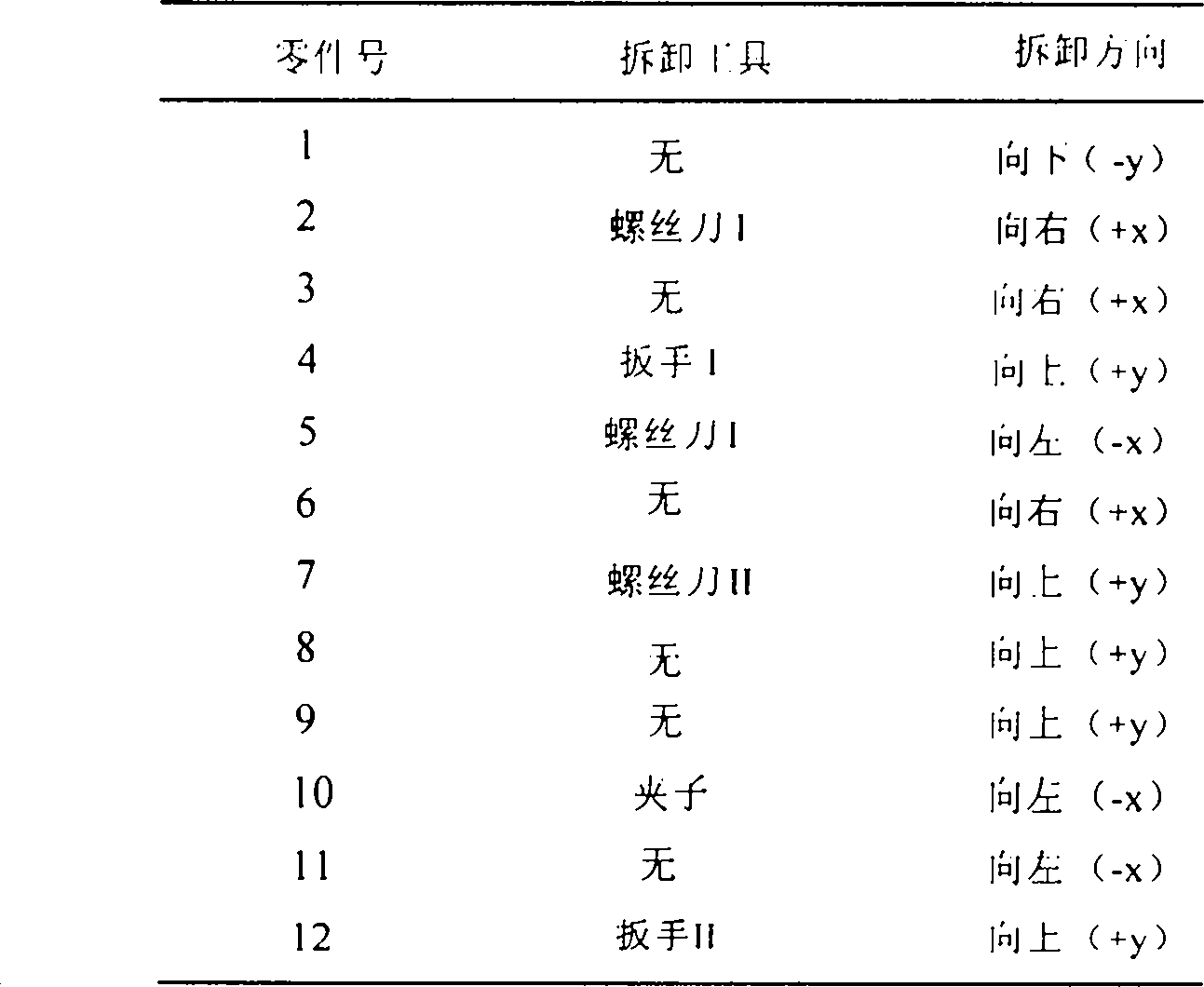

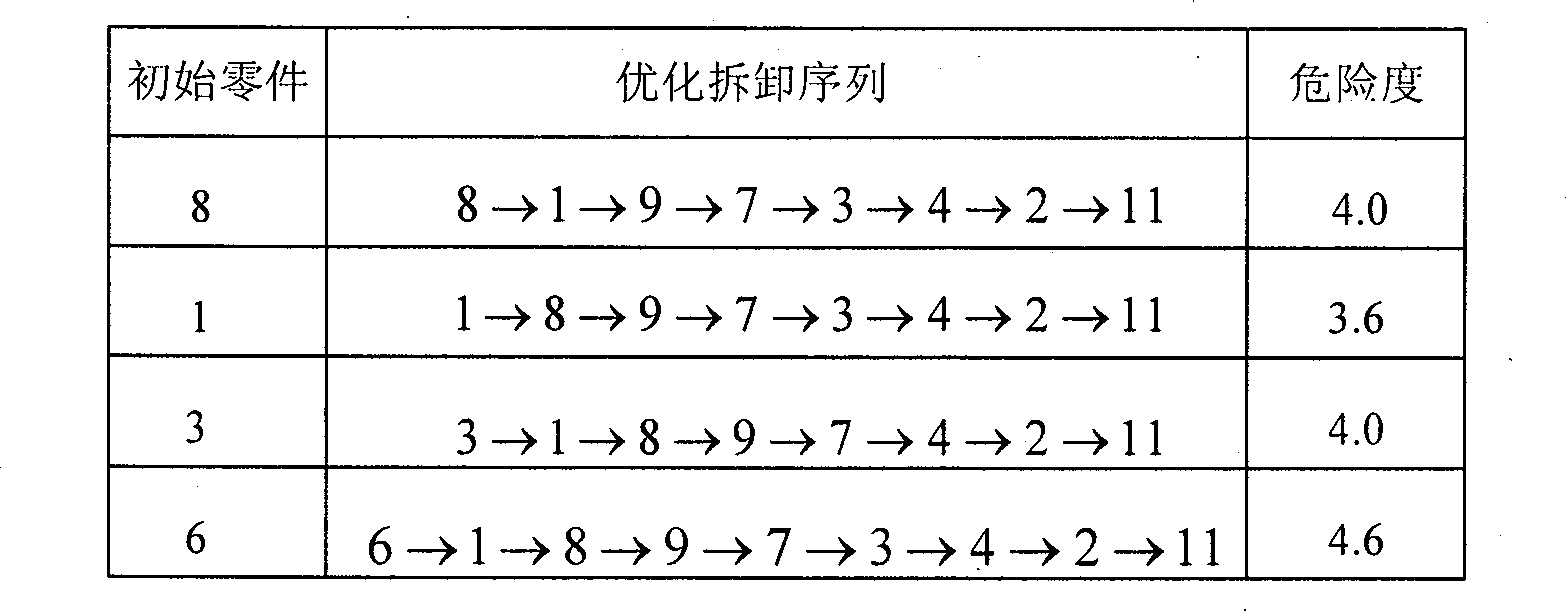

[0017] (1) Product selective disassembly modeling

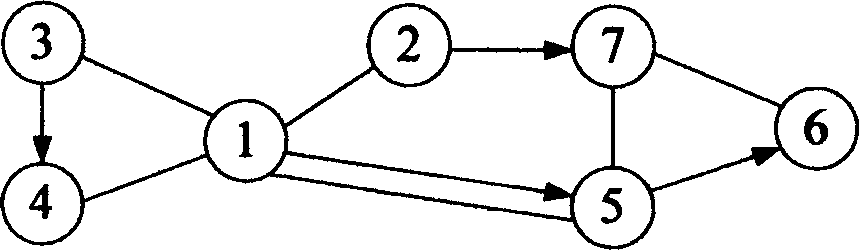

[0018] exist figure 1 Among them, the present invention uses the disassembly constraint graph to describe the disassembly constraint relationship between product components, thereby establishing a product disassembly model. The dismantling model consists of node set V, undirected edge set E and directed edge set R, denoted as:

[0019] DG = {V, E, R} (1)

[0020] Among them: V={v 1 , v 2 ,...,v n} is a collection of nodes, representing a collection of disassembled parts, and n is the number of disassembled parts.

[0021] E={e 1 , e 2 ,...,e m} is the set of directed edges. Indicates the priority constraint relationship between parts, such as figure 1 Vertex 3 to vertex 4 are directed edges, indicating that part 3 is disassembled before part 4.

[0022] R={r 1 , r 2 ,...,r k} is an undirected edge set, which represents the connection constraint relationship. When there is no clear or inevitable sequential disma...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com