Planning system and method for shield body assembly sequence of shield machine

A technology for assembly sequence planning and assembly sequence, applied in manufacturing computing systems, forecasting, instruments, etc., can solve problems such as inconvenient association, inability to update in time, and inability to set assembly rules, so as to avoid increasing and reducing the complexity of sequence planning. The effect of complexity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

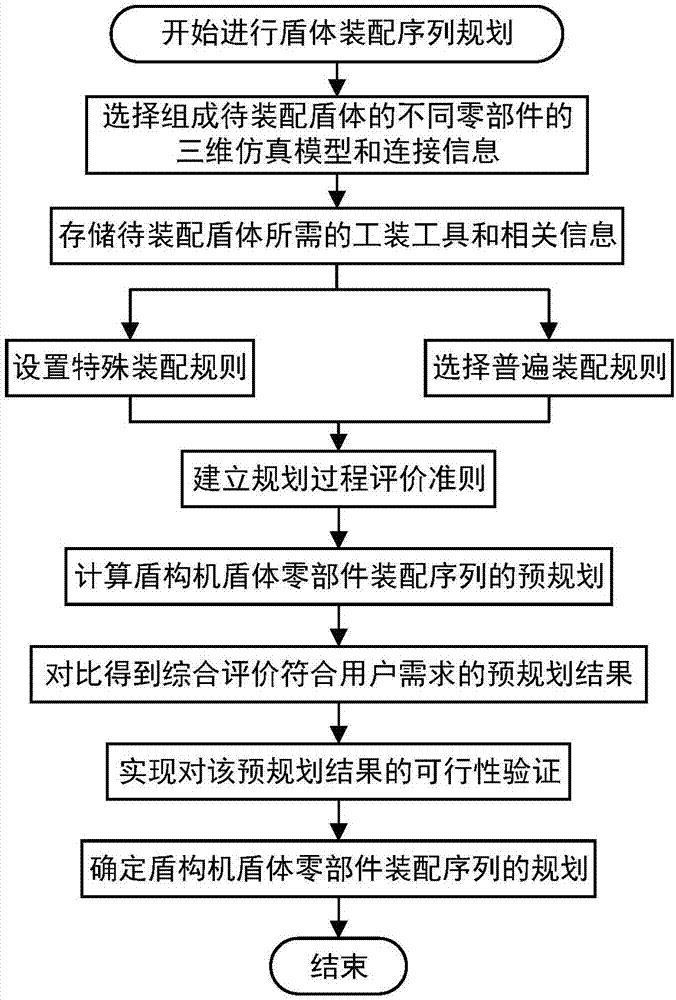

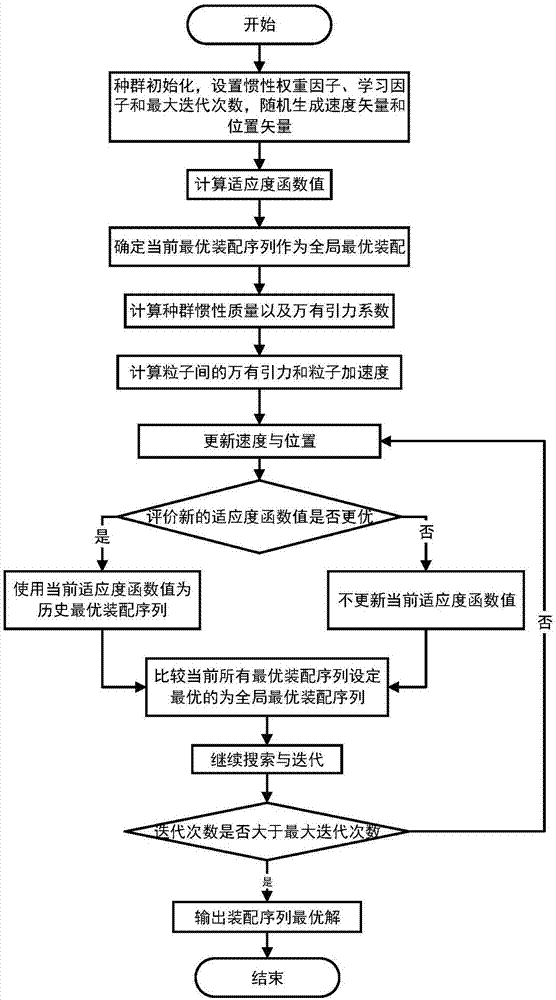

[0039] Below in conjunction with accompanying drawing and specific embodiment, the present invention is described in further detail:

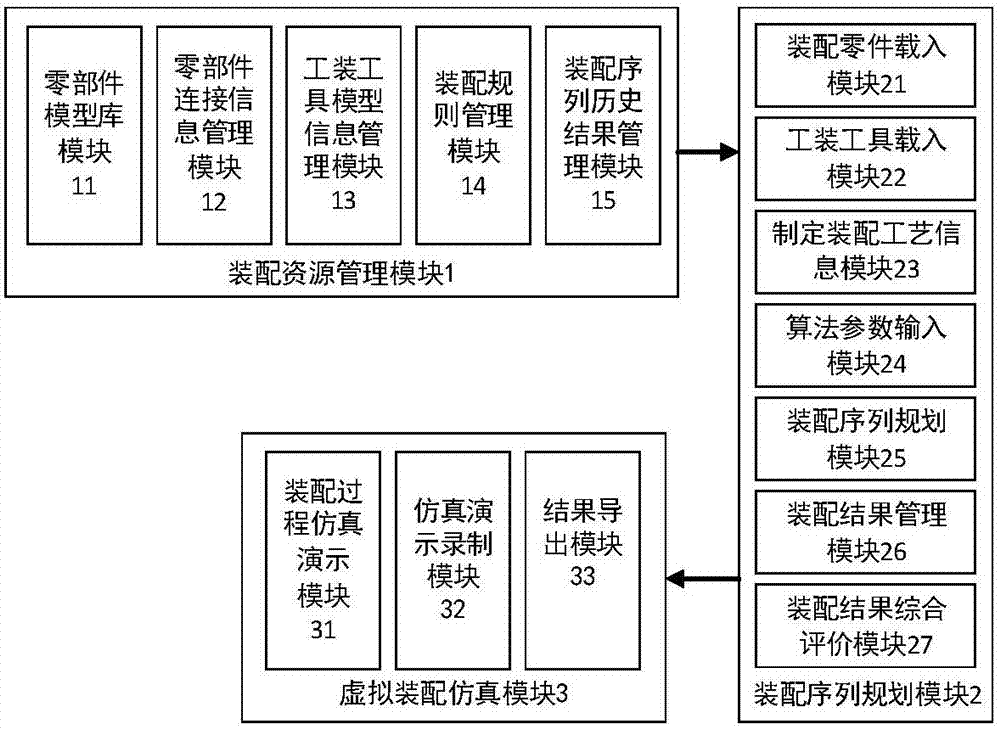

[0040] refer to figure 1 , a shield body assembly sequence planning system for a shield machine, comprising an assembly resource management module 1 connected to a commercial database MySQL Server, an assembly sequence planning module 2 and a virtual assembly simulation module 3, wherein:

[0041] The assembly resource management module 1 includes a component model library module 11, a component connection information management module 12, a tooling tool model information management module 13, an assembly rule management module 14, and an assembly sequence history result management module 15, wherein the component model library Module 11 is used to store the three-dimensional simulation model of the different parts of the shield body of the shield machine built by commercial software PROE; the parts connection information management module 12 i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com