Elastic contact-pin contact part

A technology of elastic pins and contacts, applied in the direction of contact parts, etc., can solve the problems of low strength, cannot be used alone, and the insertion force of slotted jack contacts is large, and achieves easy disassembly, low contact resistance, and contact Resistive and stable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

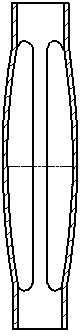

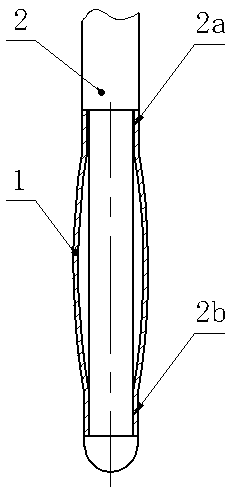

[0015] As shown in the figure, the elastic pin contact of the present invention is composed of a reed contact ring 1 and a pin pin 2. The reed contact ring 1 is drum-shaped, and the middle part is convex. The two ends of the pin 2 are respectively provided with steps 2a, 2b, and a limiting groove is formed between them, and the reed contact ring 1 is set in the limiting groove between the steps 2a, 2b at the two ends of the pin 2. The reed contact ring 1 and the step at one end of the pin pin 2 can also be fixedly connected by welding or crimping, and the other end is not fixed, so that one end of the contact ring 1 can slide freely along the limit groove of the pin pin 2 . In addition, in order to increase the elasticity of the reed contact ring 1, axial waist-shaped holes are uniformly arranged around the ring. The step 2b at the butt joint end of the pin pin 2 can be made into a semicircular structure, which is convenient for butt joint with the jack contact, and the inser...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com