Hot rolling and finish rolling multi-level threading speed control method

A technology of strip threading speed and control method, applied in rolling mill control device, metal rolling, metal rolling, etc., can solve problems such as hidden dangers of scrap steel

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

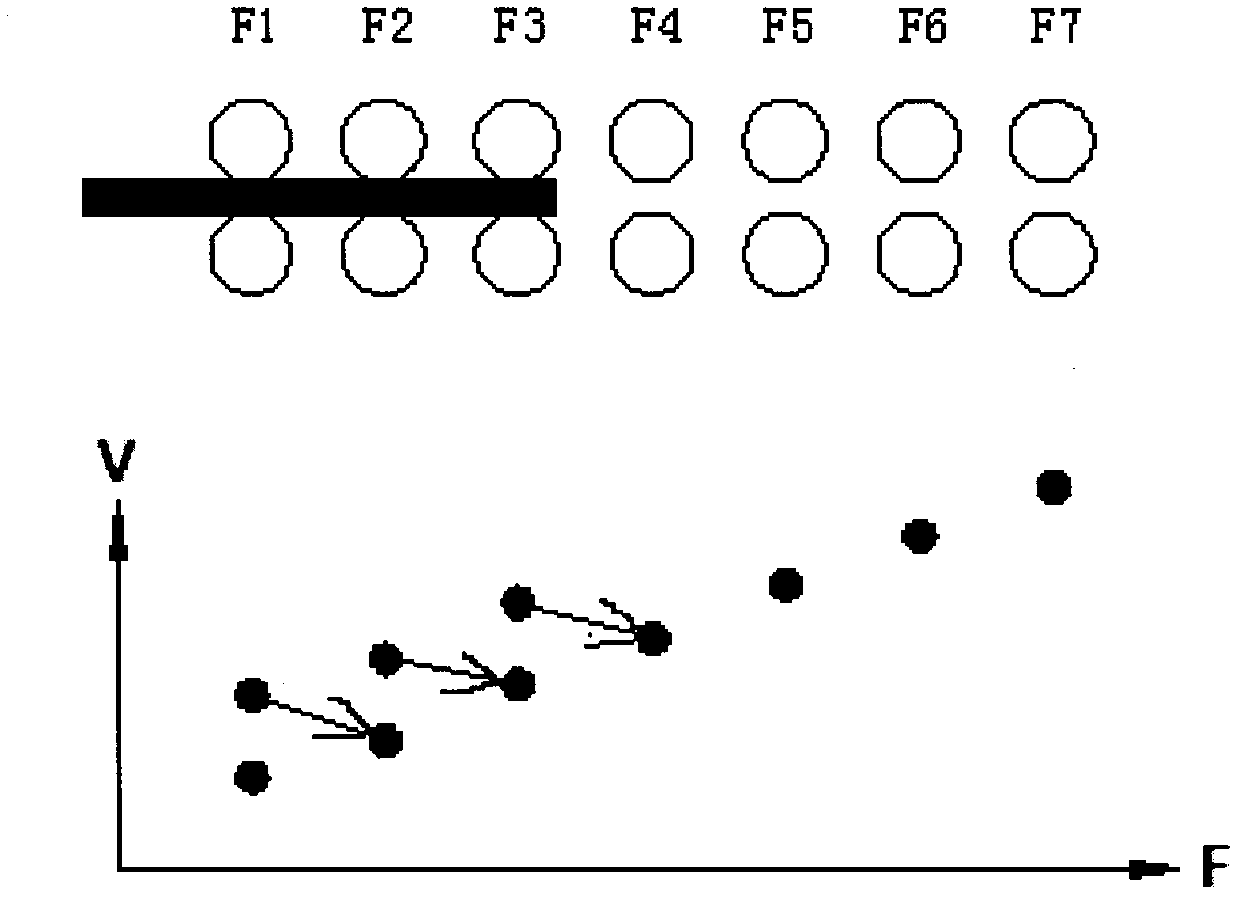

[0023] For the hot rolling and finishing rolling multi-stage threading speed control of this embodiment, refer to figure 1 , taking the 7-stand (F1-F7) finishing mill equipped with finish rolling temperature and strip end position monitoring, the rolled strip thickness is 1.80mm, and the target finish rolling temperature is 880±20°C as an example, the longitudinal The coordinate V is the belt threading speed, and the abscissa F is the rack. The specific steps are as follows:

[0024] (1) When rolling the first piece of strip steel, the initial strip threading speeds of the strip steel in the 7 racks are determined to be 1.22m / s, 2.30m / s, 3.59m / s, 5.36m / s which increase linearly .

[0025] 1.22*16.29=2.30*8.60=3.59*5.52=5.36*3.70=7.49*2.64=9.62*2.06=11.00*1.80=C, so the principle of equal flow per second is satisfied.

[0026] (2) When the strip head leaves the last stand F7, the instrument detects that the average actual temperature of the strip head is 852°C, which is lower...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com