A wire feeding device for a multifunctional terminal machine

A multi-functional terminal and wire feeding device technology, which is applied in the direction of line/collector parts, electrical components, circuits, etc., can solve problems such as troublesome operation and affecting the effect of lead wire devices, so as to increase the speed of threading and improve work efficiency , Simple and convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

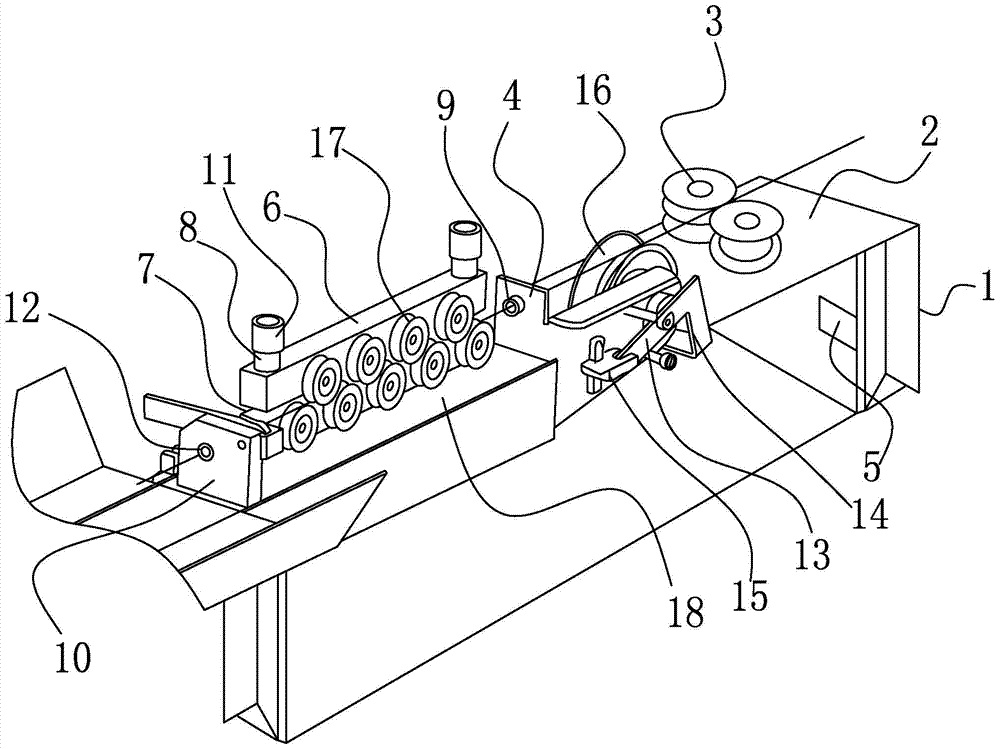

[0015] Example: such as figure 1 As shown, a wire feeding device for a multifunctional terminal machine includes a support frame 1, a wire feeding plate 2 and a correction plate 18 provided on the support frame 1, and a wire feeding wheel is arranged between the wire feeding plate 2 and the correction plate 18 device; the wire feeding plate 2 is provided with a pair of wire feeding wheels 3, a motor 5 that drives a pair of wire feeding wheels 3 to rotate relatively synchronously, the motor 5 is arranged on the support frame 1, and the wire feeding wheel device includes a guide plate 4, The driven wheel 16 and the adjusting device for adjusting the driven wheel 16, the guide plate 4 is provided with a guide pipe 9 corresponding to the center of the upper end of the driven wheel 16, and a pair of wire feed wheels 3 form a wire feeding channel , the wire feeding channel corresponds to the guide tube 9, the correction plate 18 is provided with a first adjustment plate 6 and a seco...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com