Patents

Literature

45results about How to "Fast threading speed" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

A controlling method for hot rolled strip threading of a continuous mill set

ActiveCN102688894AThreading speed controlEasy to controlTemperature control deviceMetal rolling arrangementsTemperature controlStrip steel

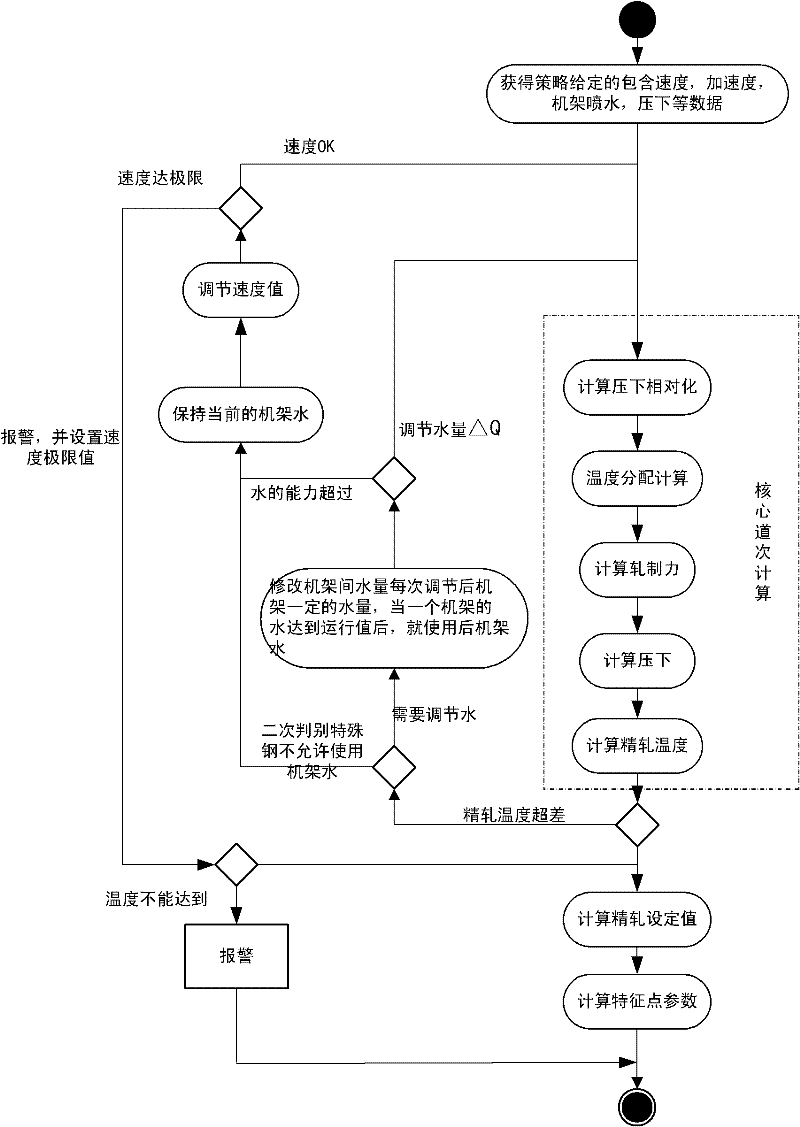

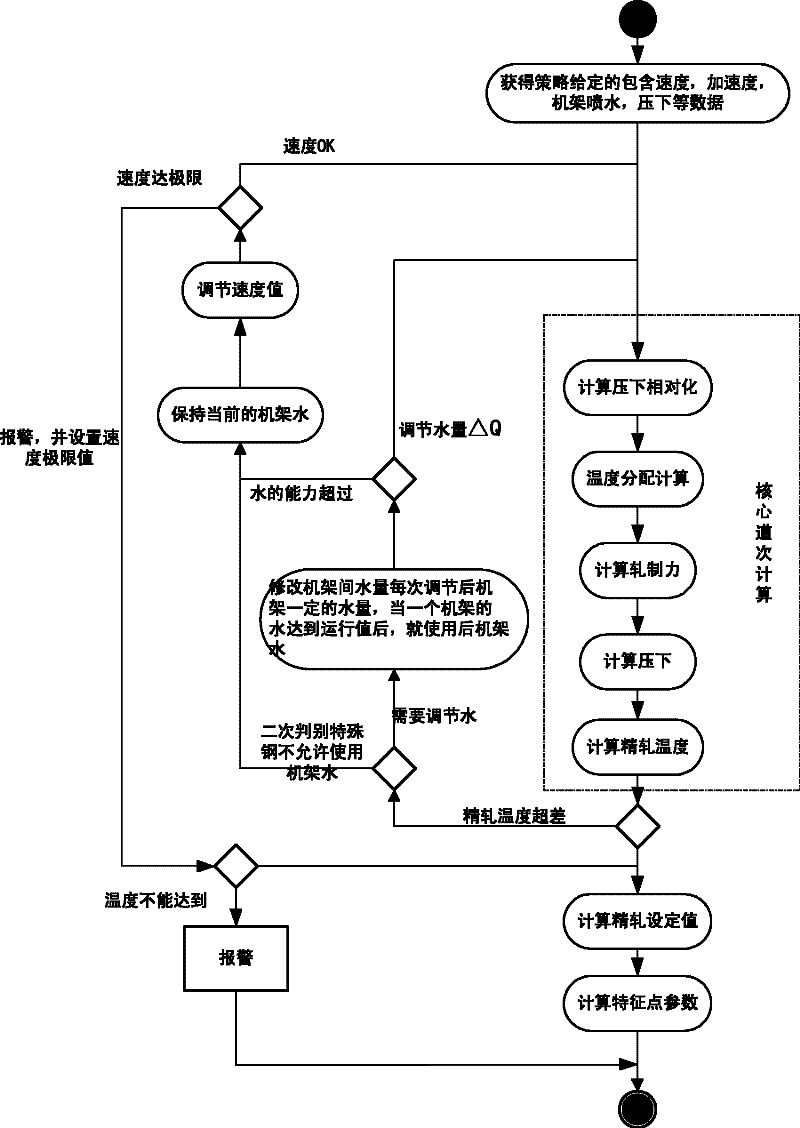

The invention discloses a controlling method for hot rolled strip threading of a continuous mill set. The controlling method comprises the steps of acquiring the basic parameters given by rolling strategy, calculating core passes, and continuously adjusting the strip-threading speed or the water yield according to the calculating result. A set value of precision rolling is determined according to the consistency between the adjusted precision rolling temperature and the target precision rolling temperature and the obtained data, or alarm is given when the condition is unavailable. The method is mainly characterized by controlling the strip-threading speed of the related continuous mill by determining a quadratic layer, raising the controlling accuracy in the strip-threading speed of related strip steel by controlling the strip-threading speed of related strip steel and employing the temperature control technique based on speed iteration deformation.

Owner:BAOSHAN IRON & STEEL CO LTD

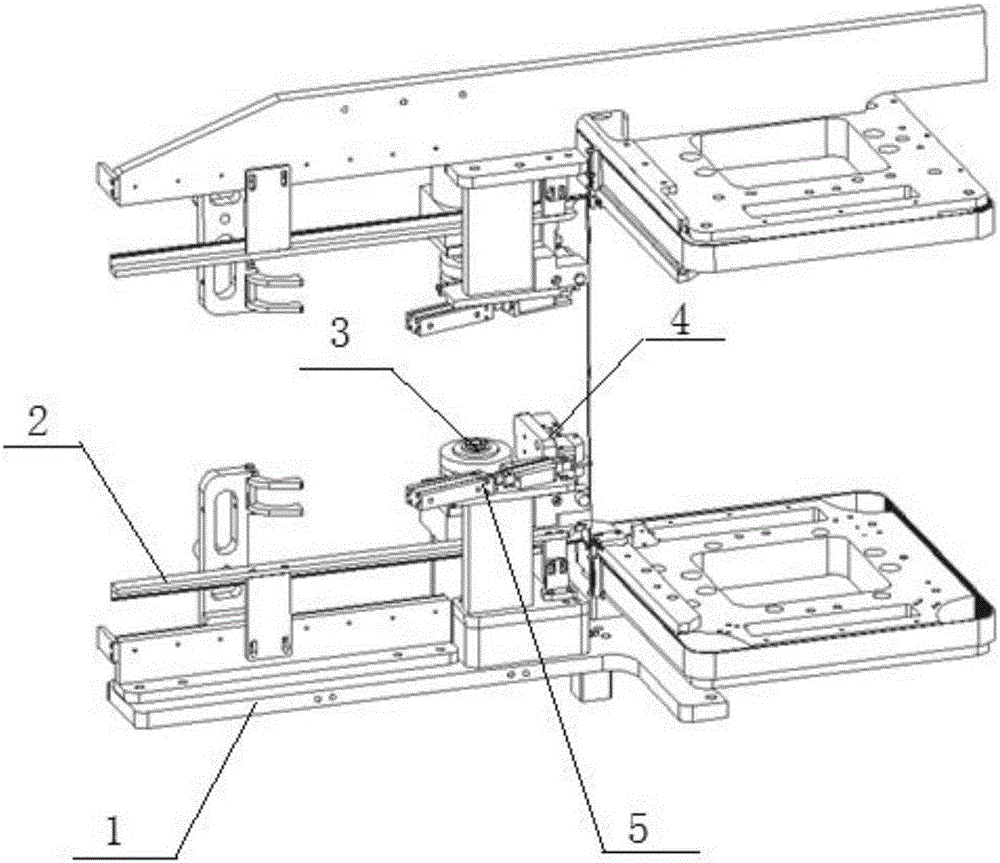

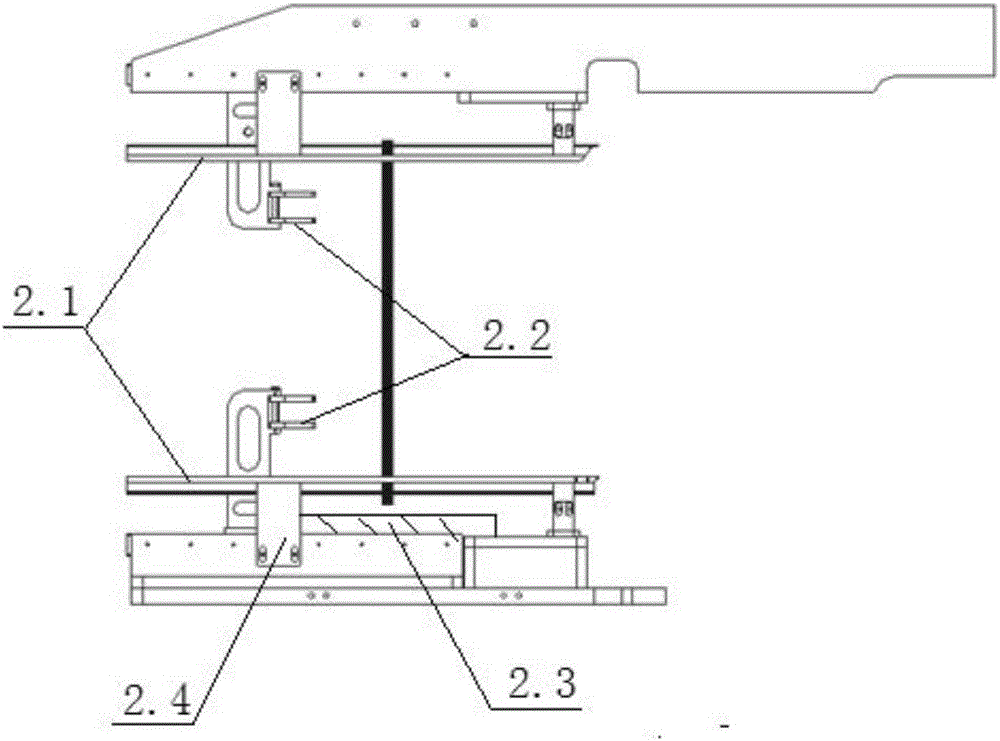

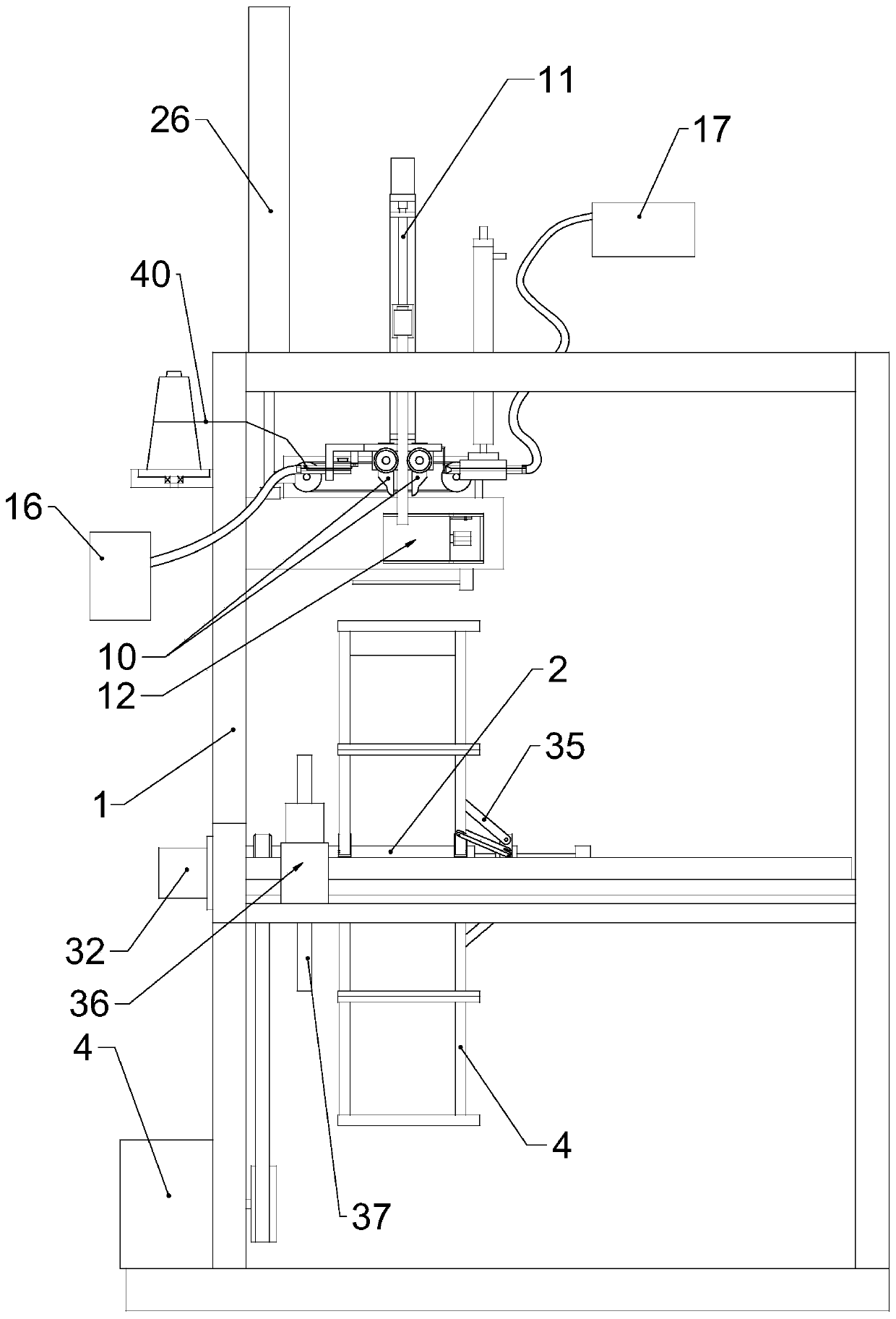

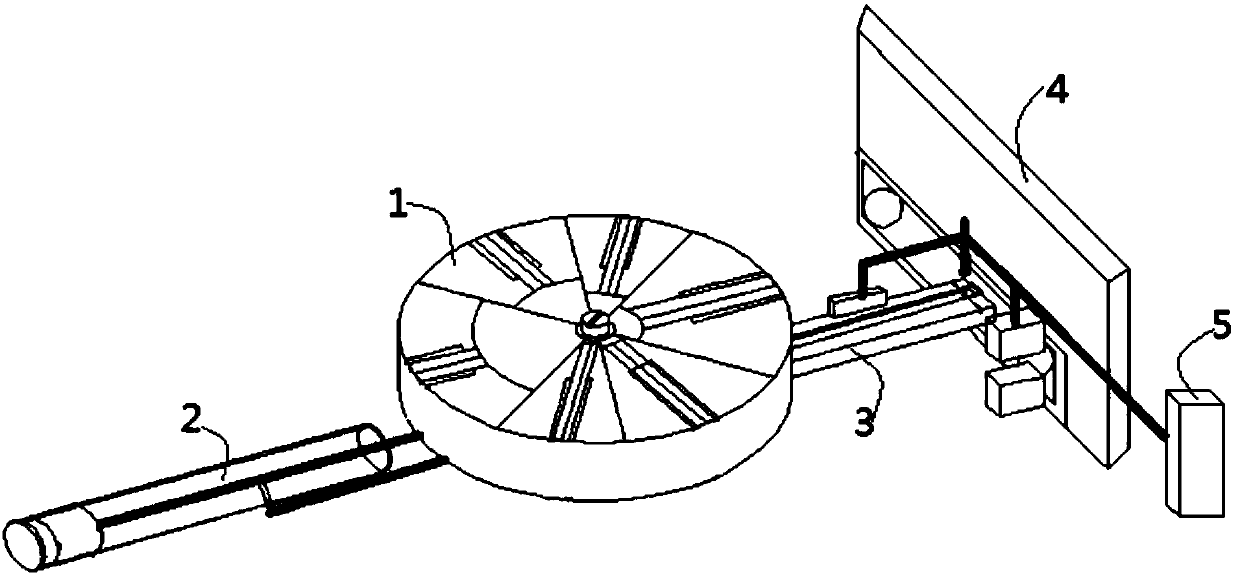

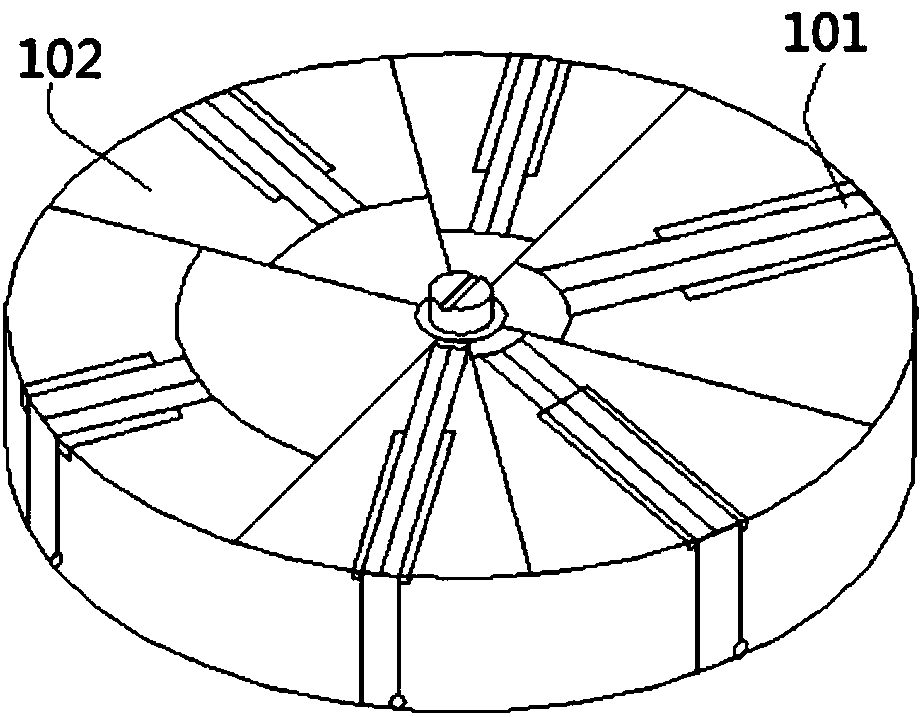

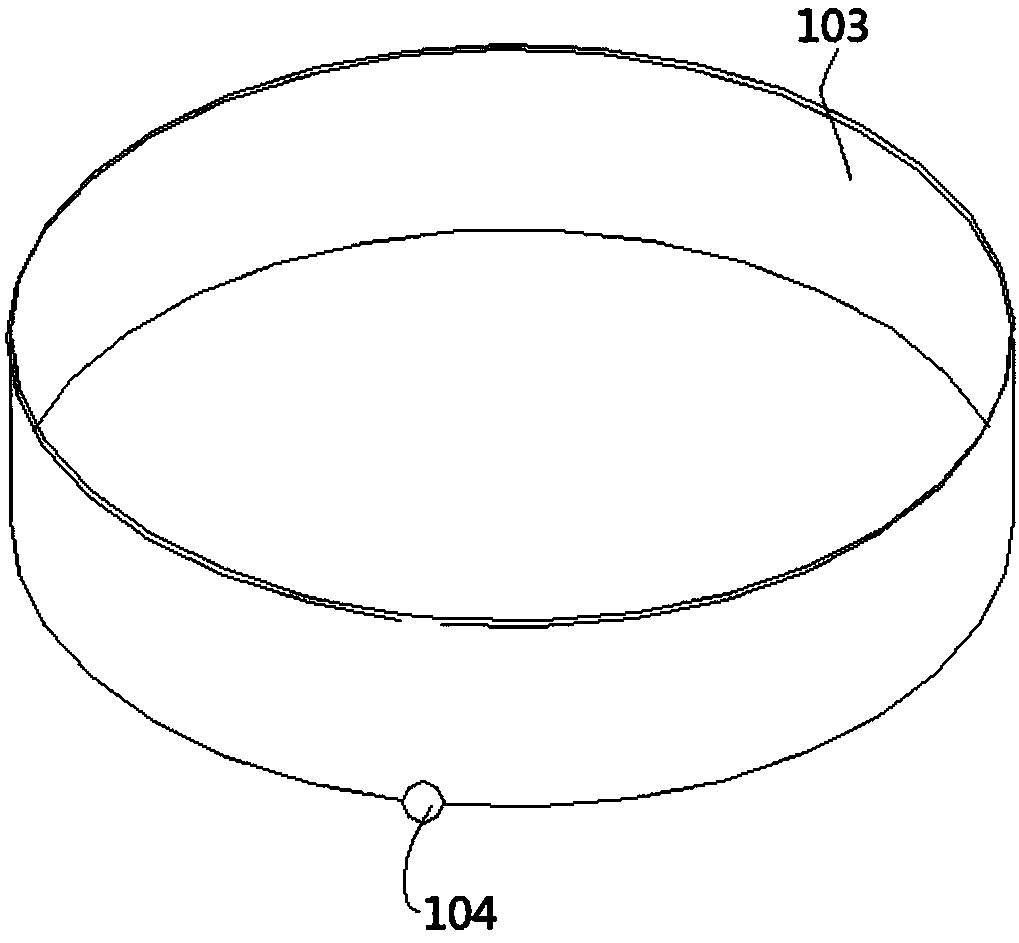

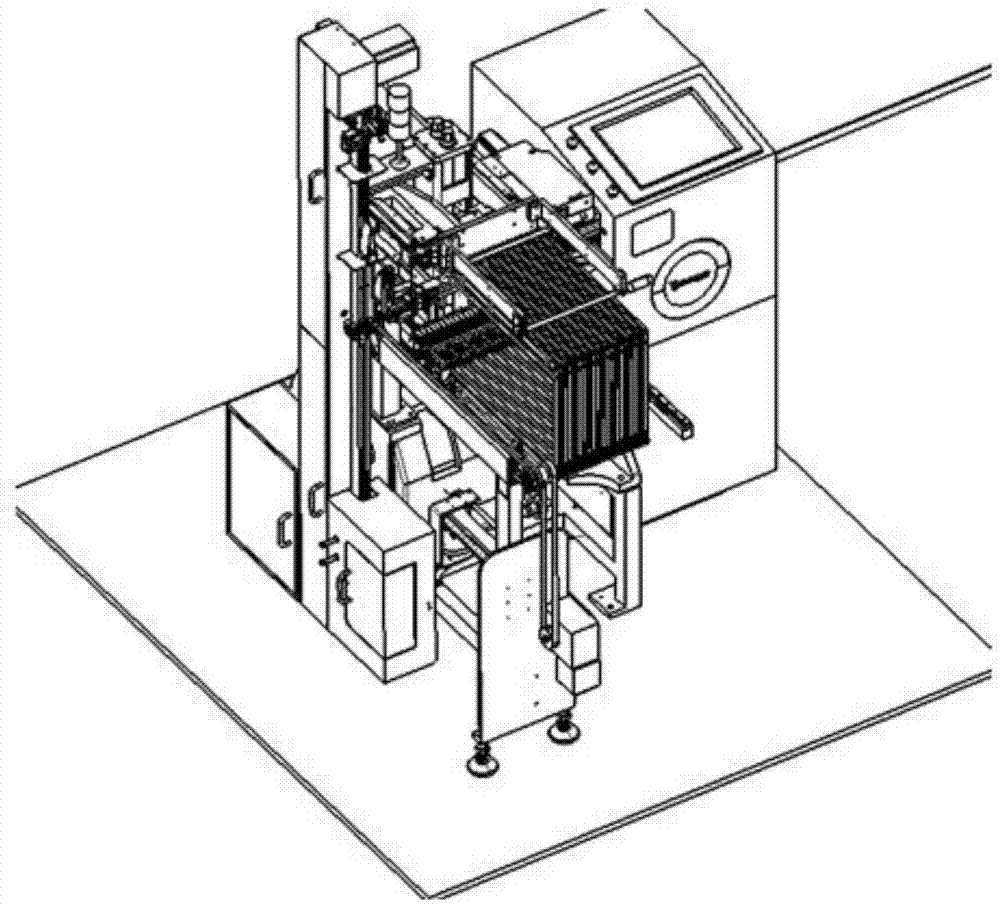

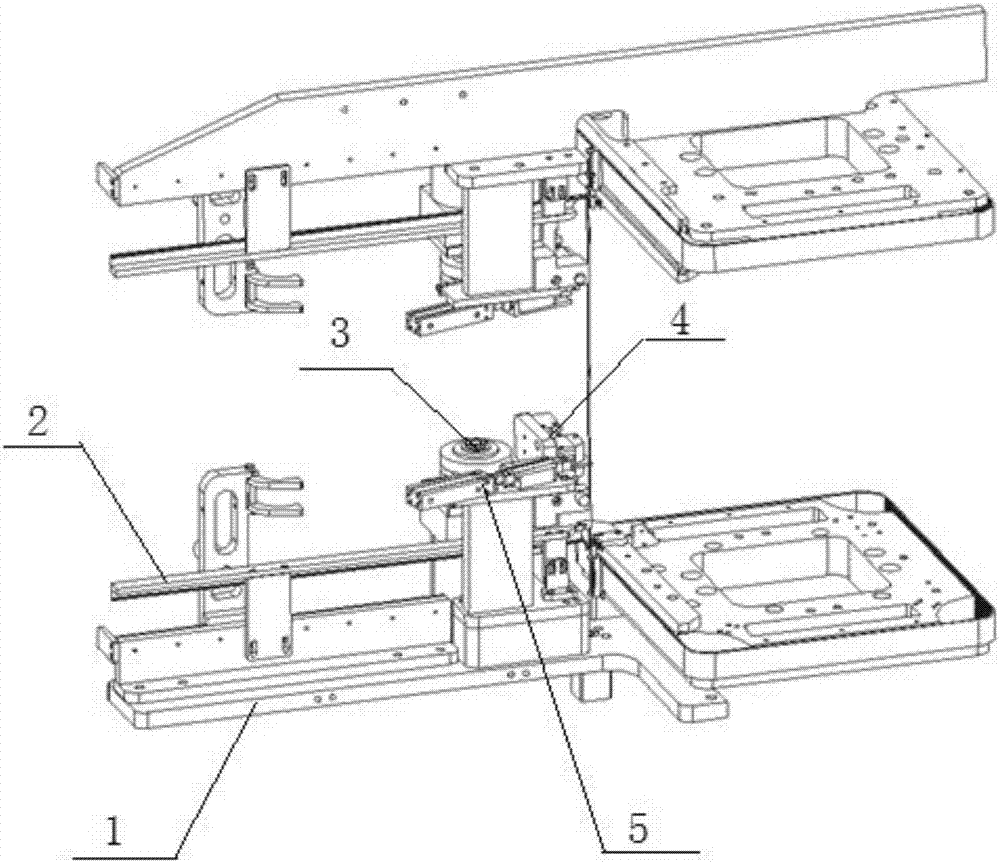

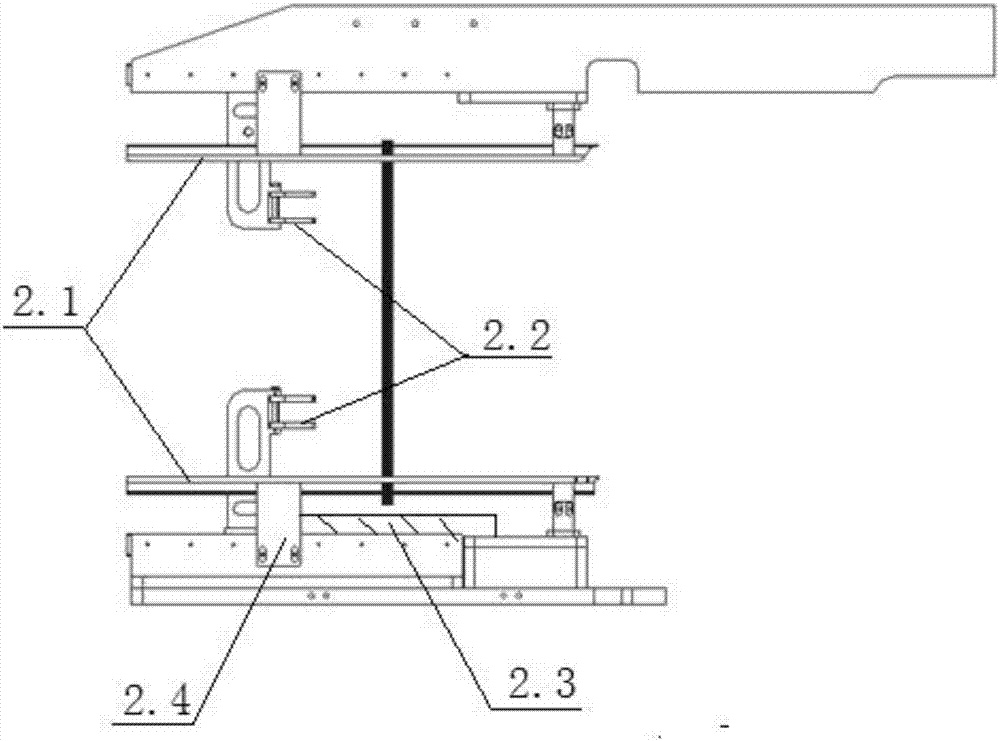

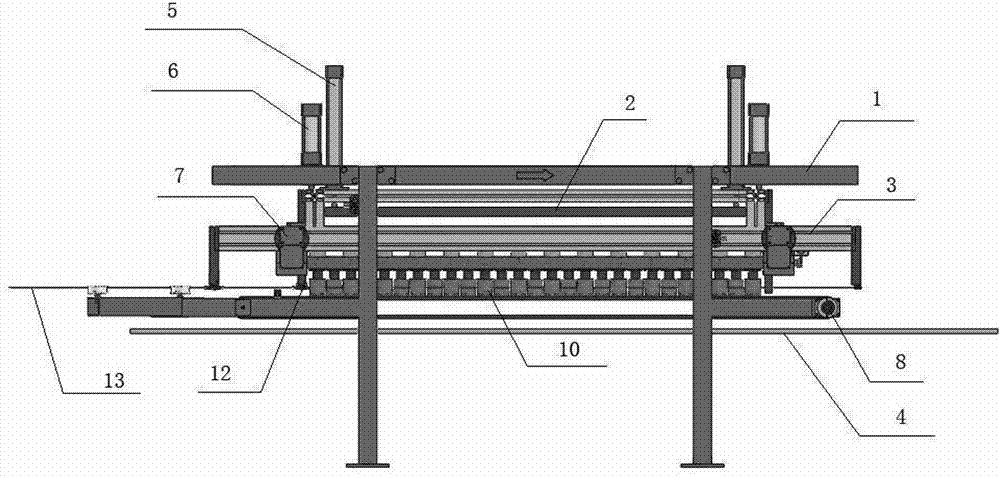

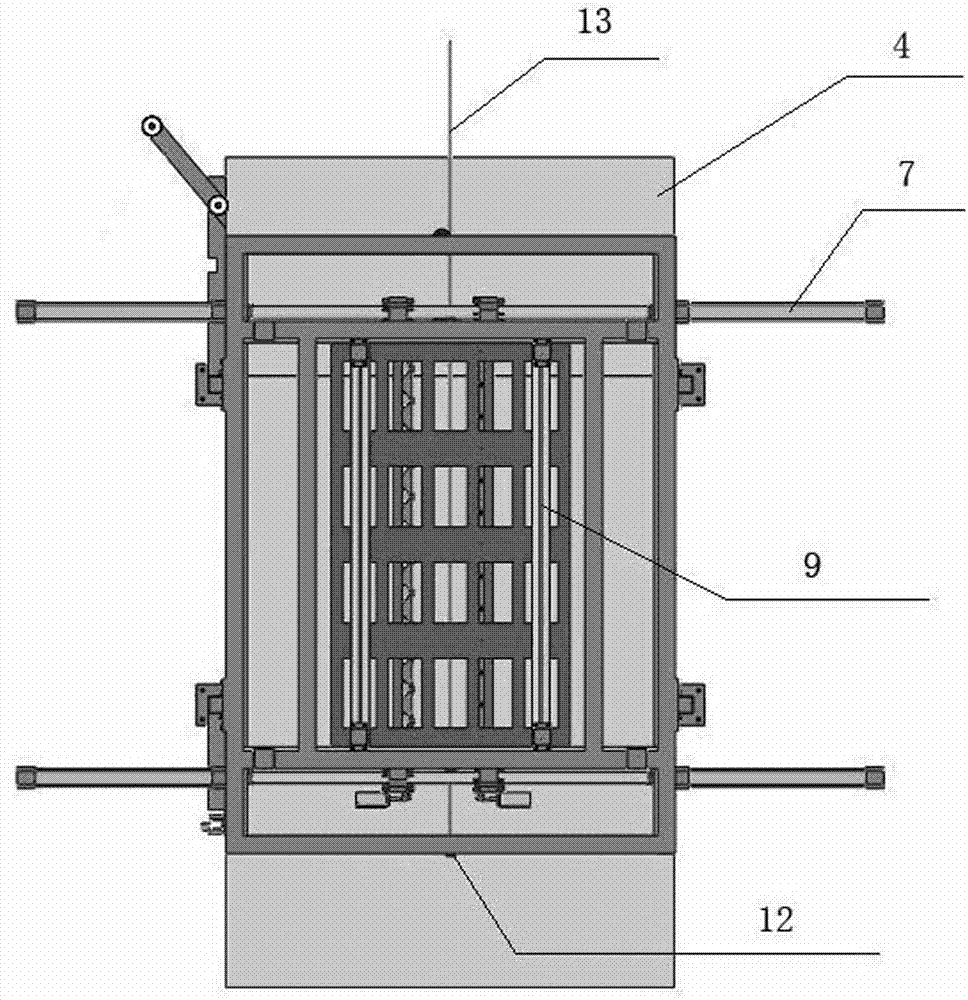

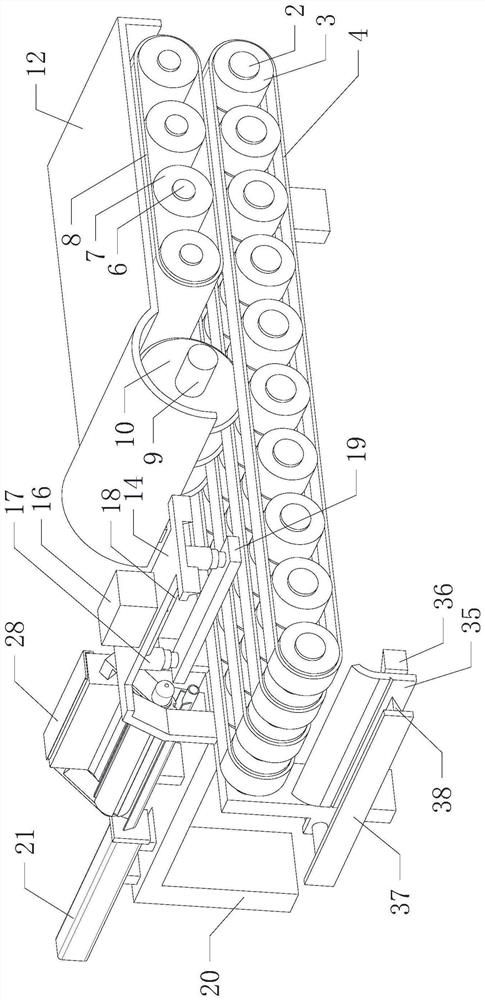

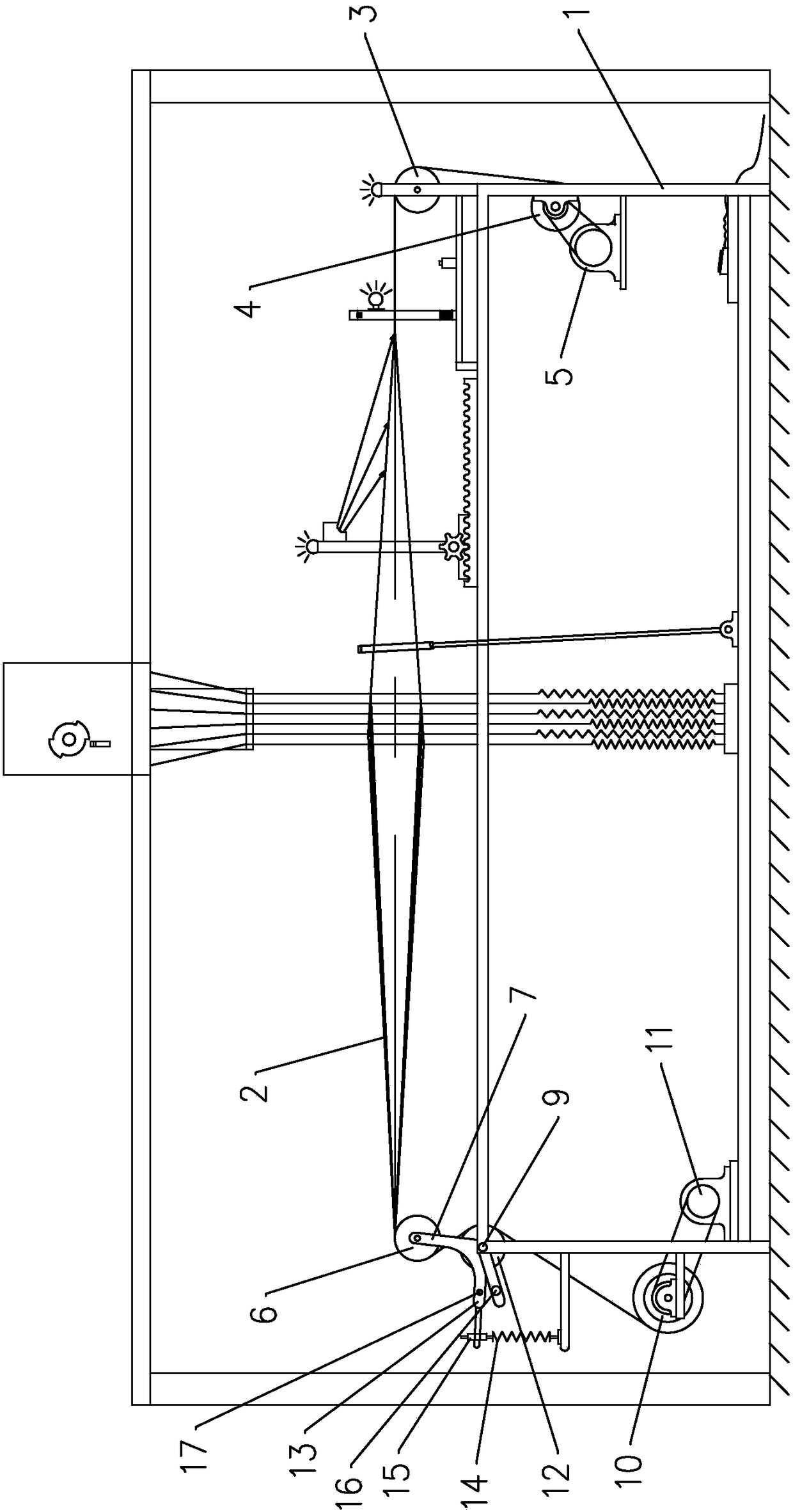

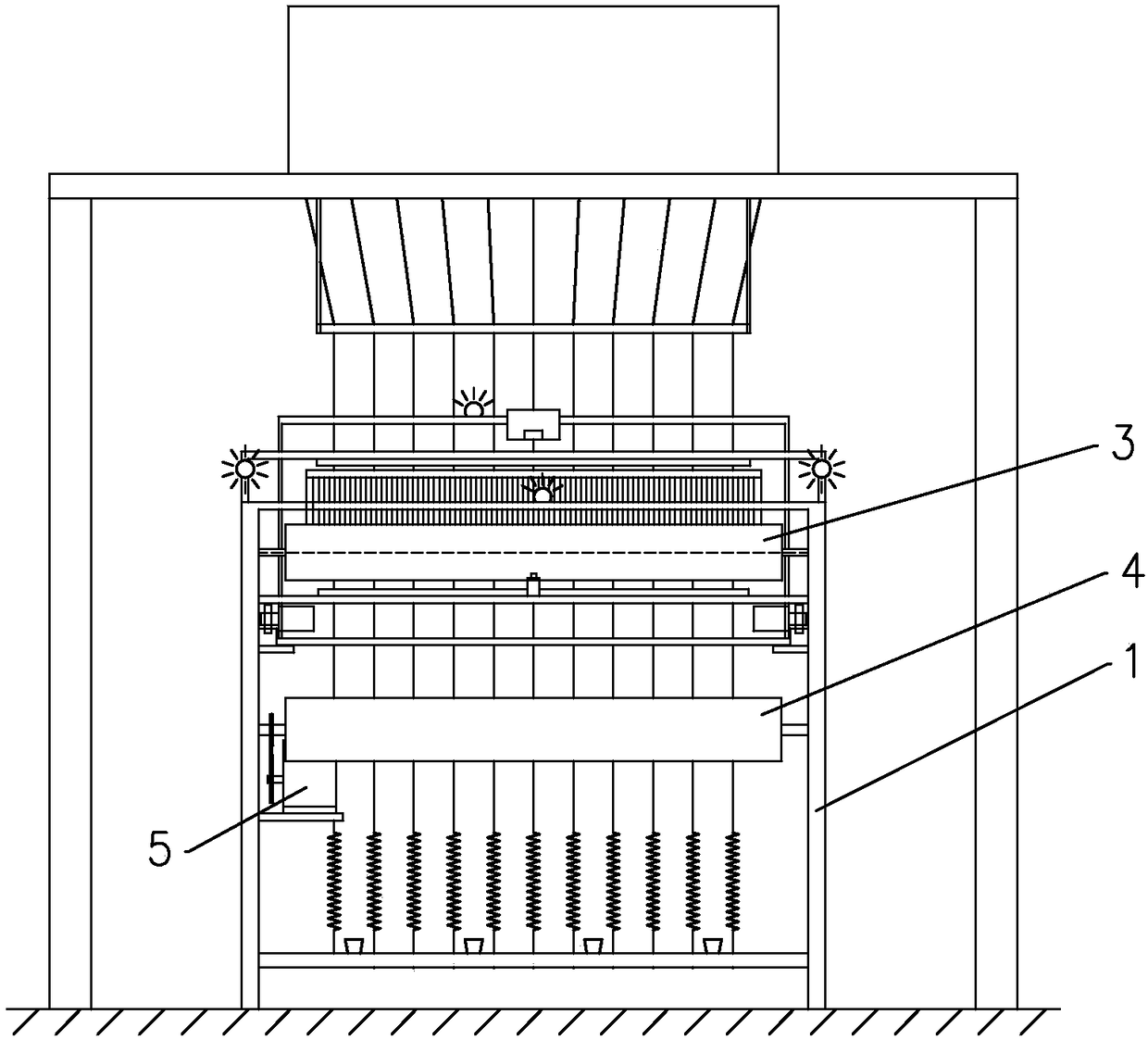

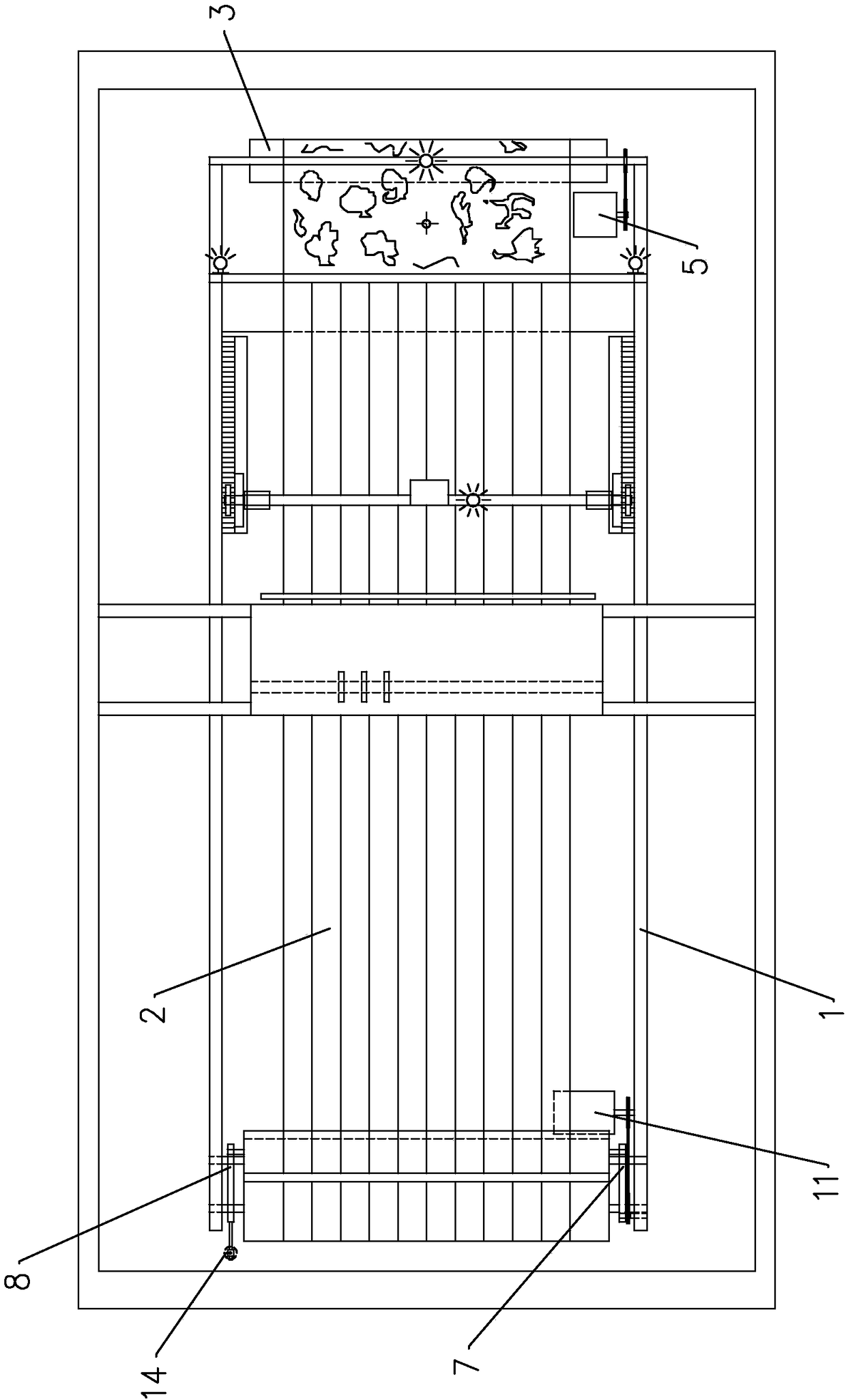

Automatic yarn drafting equipment

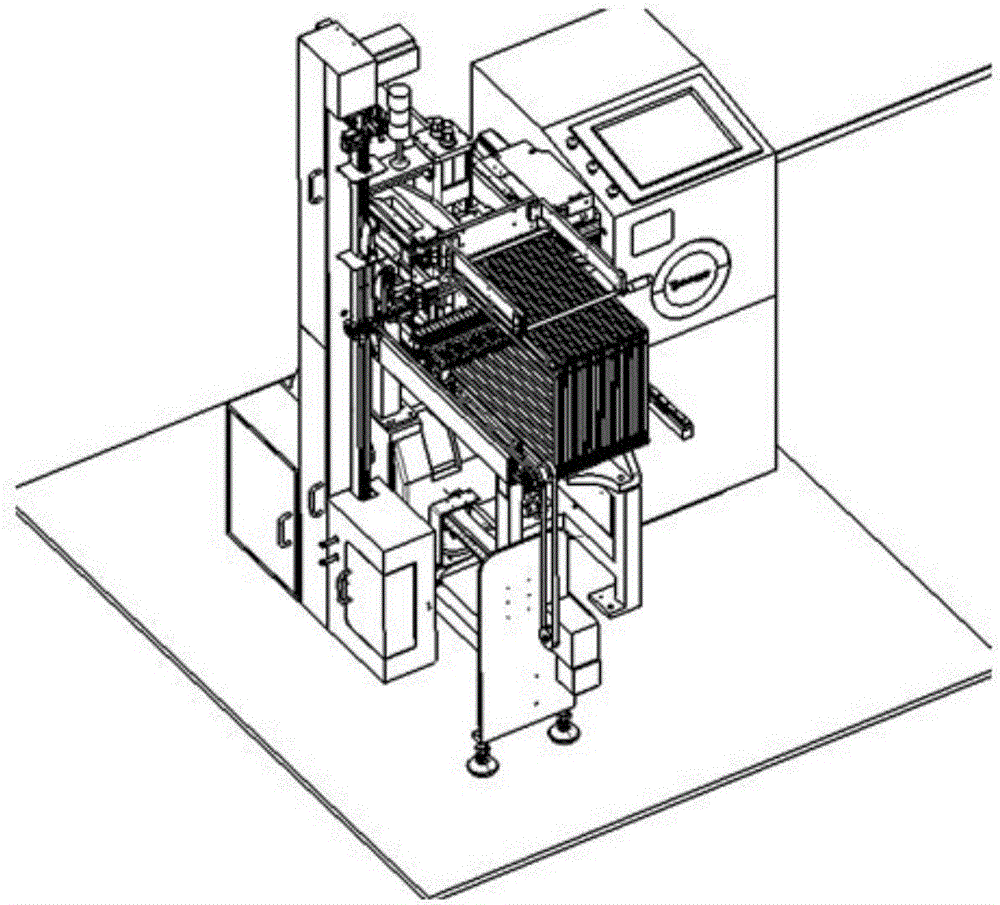

The invention relates to automatic yarn drafting equipment suitable for sample looms. The automatic yarn drafting equipment comprises a heddle feeding mechanism mounted on a rack, a heddle conveying mechanism, a yarn feeding mechanism, a yarn hooking mechanism, a reed feeding mechanism and a heddle arranging mechanism, the heddle feeding mechanism stores heddle at a heddle storage place at a time and conveys the same to a corresponding process position of the automatic yarn drafting equipment for single heddle separation, the reed feeding mechanism and the heddle arranging mechanism are at tail-end workstations of the equipment, and the heddle penetrates among workstations; the heddle conveying mechanism conveys the heddle which is separated successfully to the workstations for working, the yarn feeding mechanism conveys yarn equal in length at a yarn storage place to the top end of the equipment, the yarn hooking mechanism utilizes an arrow belt to hook vertical yarn at a yarn feeding workstation into the heddle and steel reeds and stores ends of the yarn at the tail end of the yarn hooking mechanism, the reed feeding mechanism orderly conveys the steel reeds, each steel reed gap allows 1-3 yarns to penetrate, and the heddle arranging mechanism sequentially arranges the heddle which successfully penetrate the yarns according to a set sequence.

Owner:JIANGYIN TONGYUAN TEXTILE MACHINERY

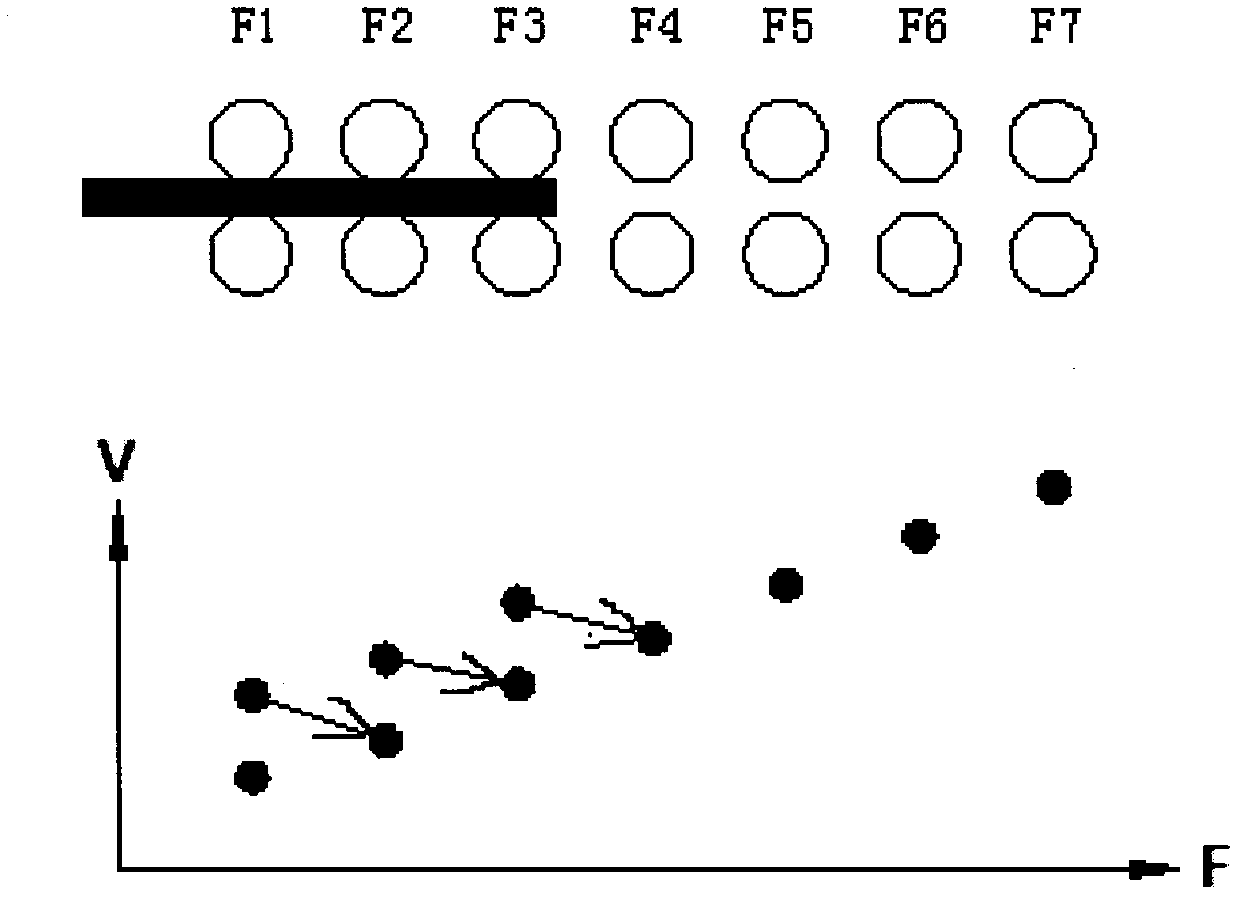

Hot rolling and finish rolling multi-level threading speed control method

ActiveCN103170506AFast threading speedMaintain smooth rolling deliveryRoll mill control devicesMetal rolling arrangementsStrip steelMaterials science

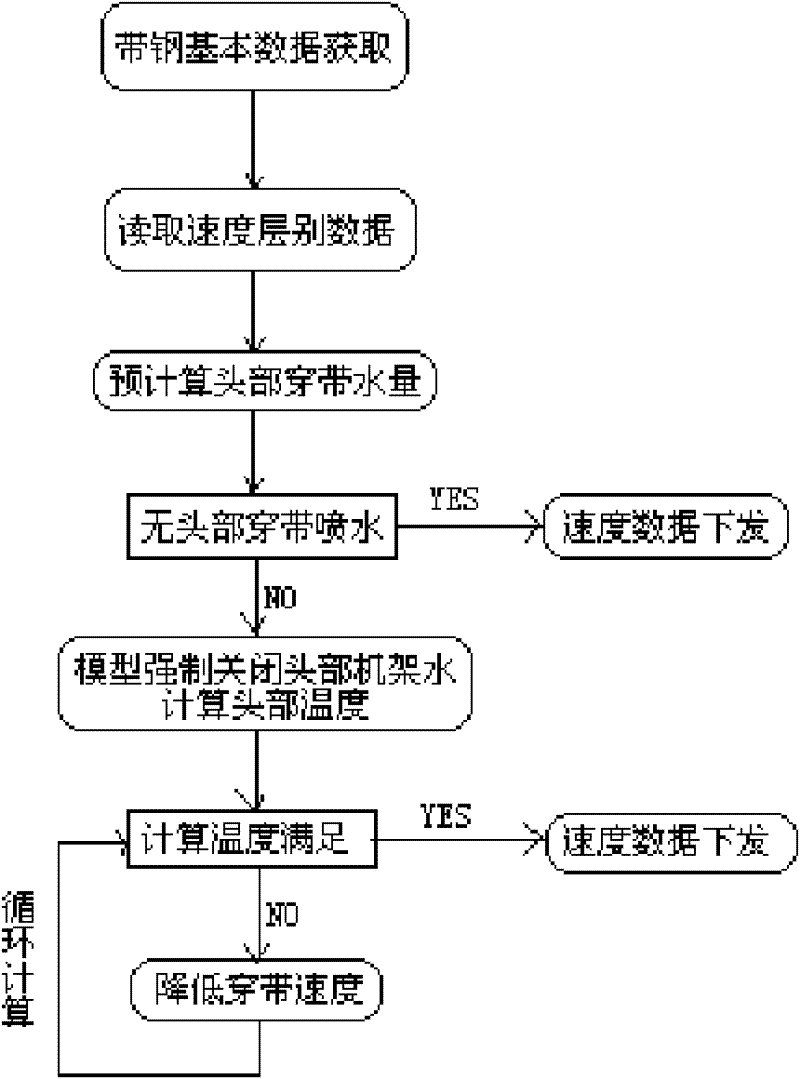

The invention relates to a hot rolling and finish rolling multi-level threading speed control method, and belongs to the technical field of steel rolling control. According to the hot rolling and finish rolling multi-level threading speed control method, in a group of steel rolling mill provided with finish rolling temperature and strip steel end location monitoring, the initial threading speed of each corresponding machine frame in a group of machine frames is determined as a matter of routine; when the monitored finish rolling temperature is lower than a target temperature, the speed of next time threading of a first machine frame is improved according to a scheduled speed-up ratio; if the monitored finish rolling temperature is still lower than the target temperature, the threading speed of a next machine frame is improved according to the scheduled speed-up ratio until before the middle machine frame; if the monitored finish rolling temperature is still lower than the target temperature, the second step is repeated; and after the threading, a strip steel end is output from a speed-up machine frame, enters in front of a bite steel of a next machine frame with the initial threading speed, and controls all speed-up machine frames to recover into original corresponding initial threading speeds. By means of the method to the maximum extent, the threading speed of the current machine frame can be improved appropriately to achieve the purpose that the finish rolling temperature is kept not to lower than a threshold value.

Owner:SHANGHAI MEISHAN IRON & STEEL CO LTD

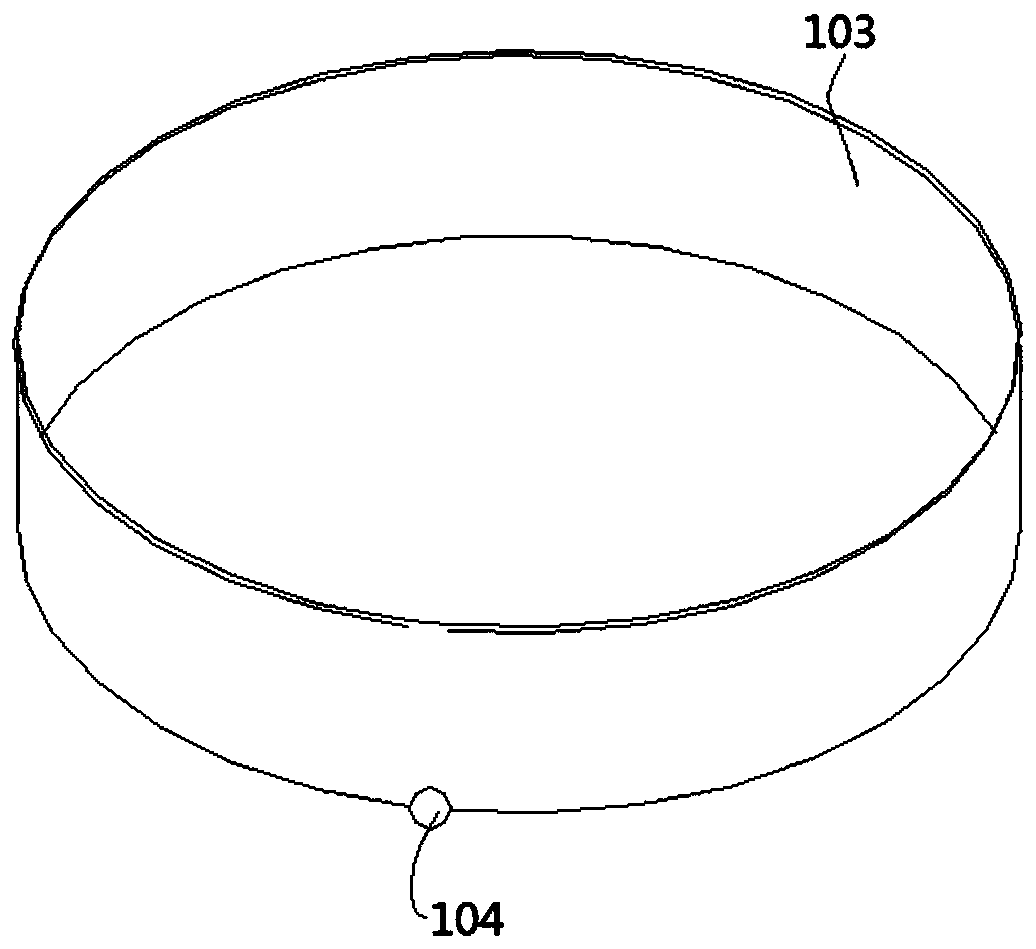

Hank reel

The invention relates to a hand reel. The hand reel comprises a rack, a horizontal rotating shaft and a main driving device for driving the rotating shaft to rotate are rotatably connected to the rack, a rotation yarn frame is fixedly connected to the rotating shaft, one end of the rotating shaft is connected with the rack, the other end of the rotating shaft hangs, a yarn guide ring is movably connected to the position, above the rotation yarn frame, of the rack, and can be parallel to the axial direction of the rotating shaft to move back and forth, a yarn guide driving device used for driving the yarn guide ring to move back and forth is arranged on the rack, the hand reel can greatly shorten the axial length of the rotation yarn frame, rotating shaft loads can be reduced, one end of the rotating shaft hangs to facilitate falling of hand yarn, the rotation yarn frame can wind one piece of hand yarn each time, synchronous starting or synchronous stop between pieces of hand yarn doesnot exist, the idle condition of the other yarn due to one-by-one making up or gradual hank tie can be avoided, and production efficiency is effectively improved.

Owner:张家港市塘桥镇鹿苑鑫森纺纱厂

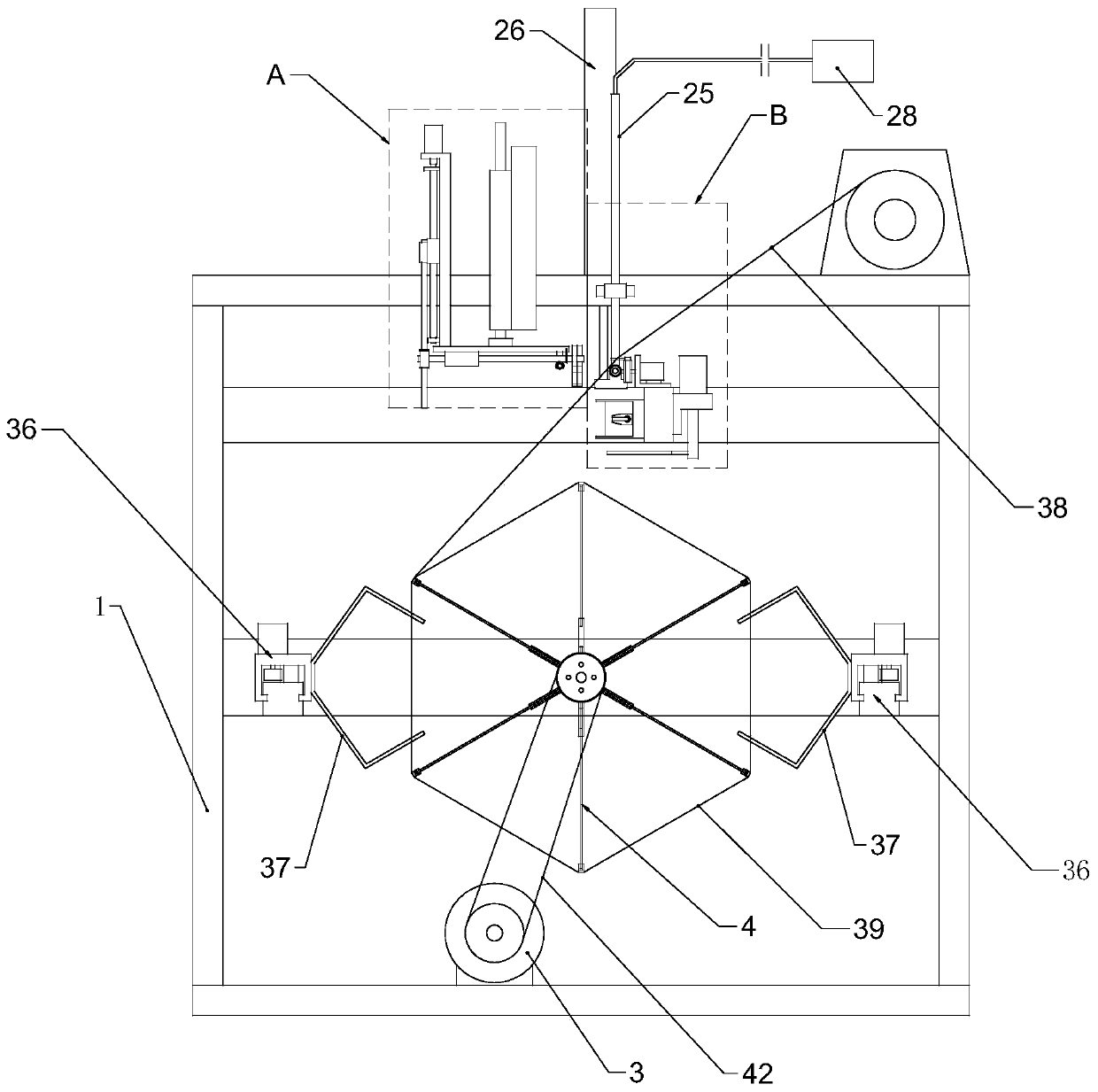

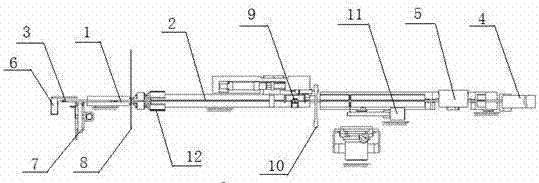

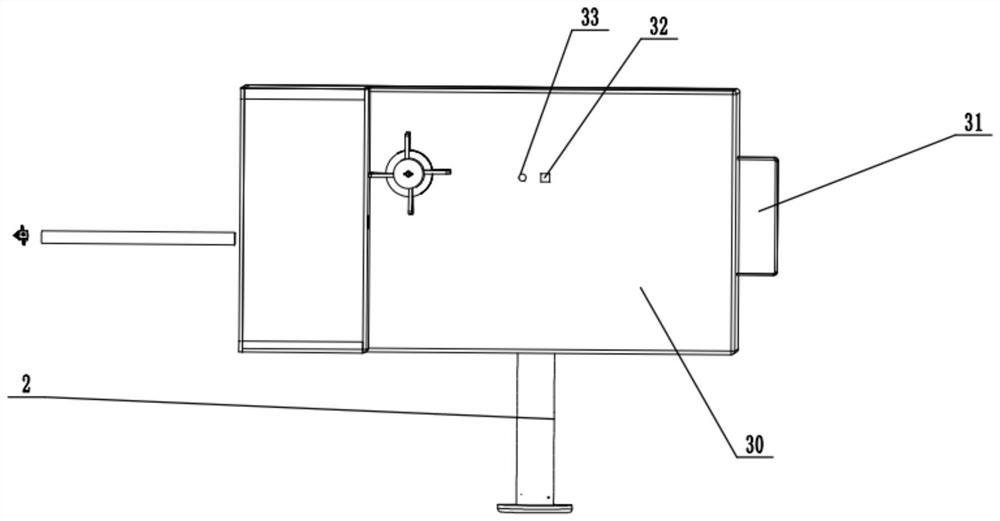

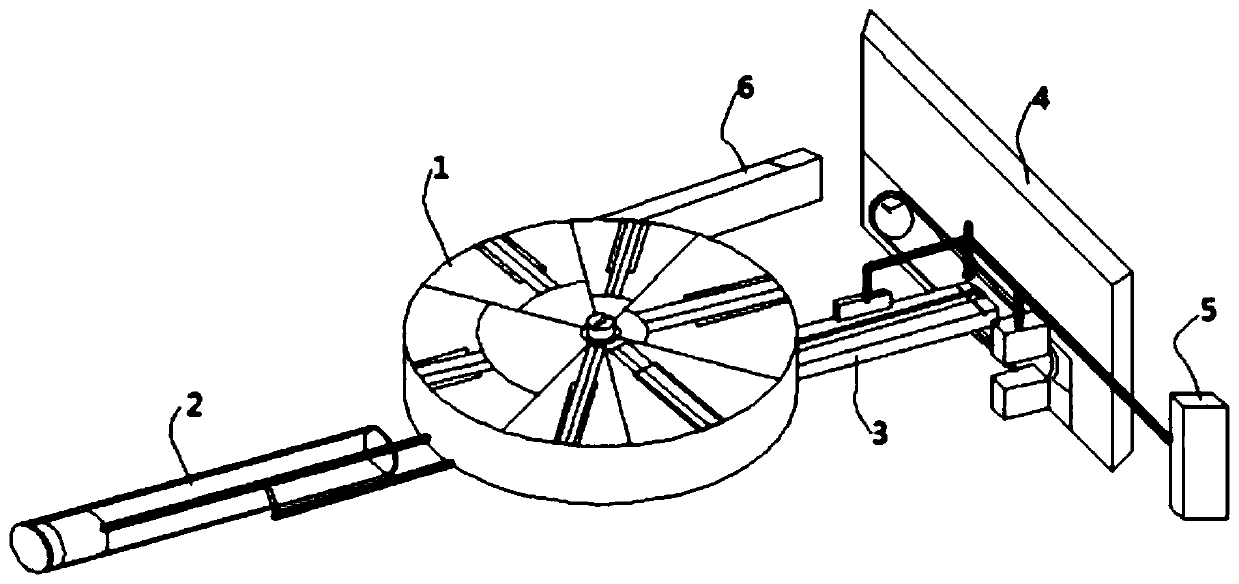

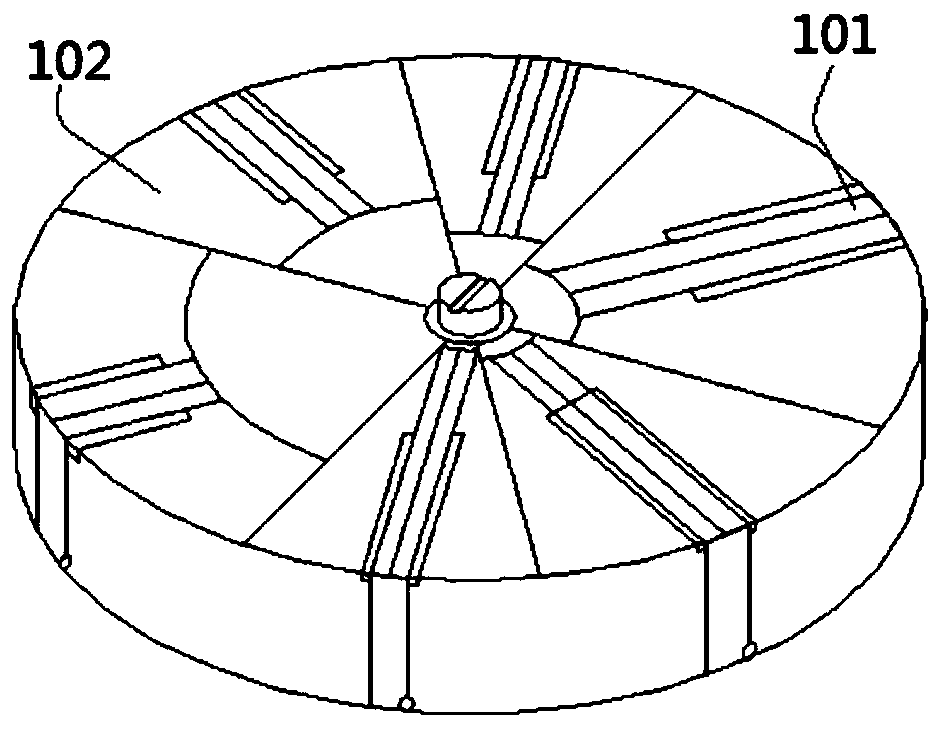

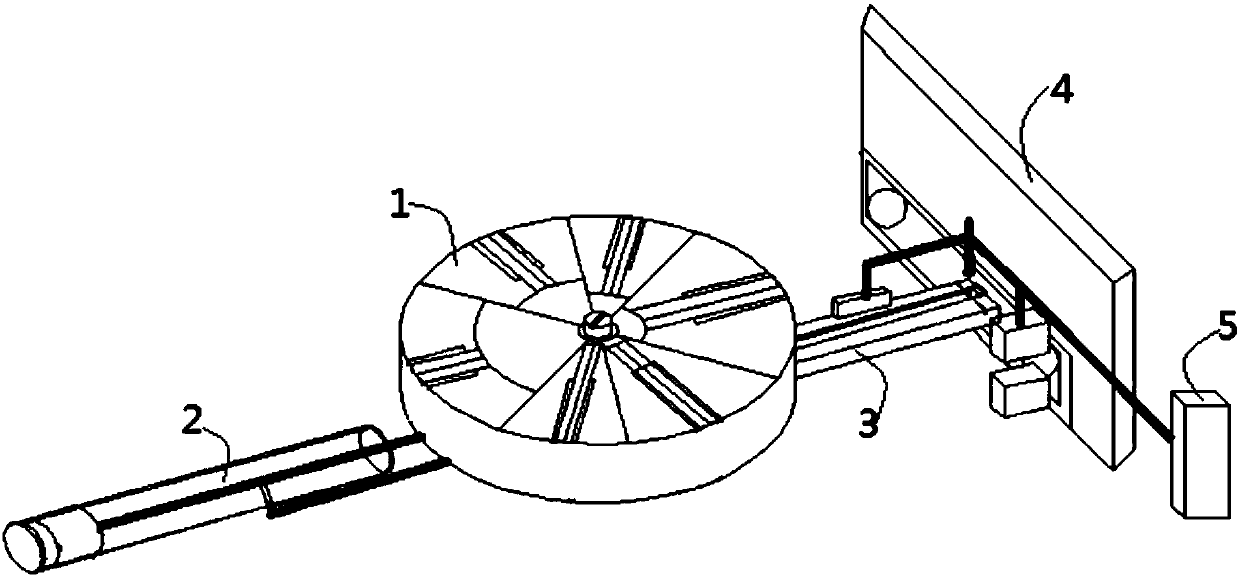

Intelligent optical automatic threading system and method for medium-speed wire-cut electrical discharge machine

ActiveCN106334846AIntelligent optical automatic wire threading method is simpleImprove processing efficiencyElectrical-based auxillary apparatusEngineeringMachine tool

The invention discloses an intelligent optical automatic threading system and method for a medium-speed wire-cut electrical discharge machine. The system comprises an industrial camera, a two-dimensional moving mechanism, a wire clip and the wire-cut electrical discharge machine; the two-dimensional moving mechanism is movably placed on an XY numerically-controlled workbench of the wire-cut electrical discharge machine; a molybdenum wire clamped and fixed by the two-dimensional moving mechanism is clipped by the wire clip; and the industrial camera is located on any side outside the wire-cut electrical discharge machine. The method comprises steps as follows: (1) calibration; (2) calculation of a position deviation; (3) compensation of the deviation; (4) automatic threading. The threading method is simple, the position deviation is compensated by the aid of the threading system, the automatic threading function is realized, on one hand, the threading speed is effectively increased, on the other hand, the threading accuracy and quality are improved, the machining efficiency of the medium-speed wire-cut electrical discharge machine is greatly improved, the practicability is high, and the method is an innovation for development of the medium-speed wire-cut technology.

Owner:江苏塞维斯数控科技有限公司

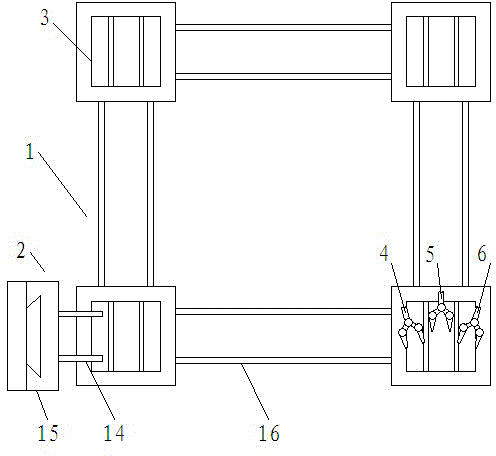

Automatic shoelace threading machine and threading method thereof

InactiveCN103416915BIncrease productivityGuaranteed tightnessShoe lace fasteningsEngineeringManipulator

The invention discloses an automatic shoelace threading machine, which comprises a working space consisting of at least two guide rails, a positioning device for positioning shoes, a workbench for clamping the shoes and at least two mechanical hands for threading shoelaces, wherein the positioning device and the mechanical hands are arranged in the working space; the workbench is arranged on the guide rails of the working space, and comprises a fixed clamping plate, movable clamping plates, a shoe tongue clamping plate, a clamping and positioning driving device for driving the movable clamping plates to move, and a shoe tongue clamping plate driving device for driving the shoe tongue clamping plate to move; the movable clamping plates are arranged on the left and right sides of the fixed clamping plate; and the shoe tongue clamping plate is arranged in a groove of the fixed clamping plate. A threading method of the automatic shoelace threading machine is also disclosed. The technical scheme has the beneficial effects that the shoelaces are automatically threaded, so that the shoelace threading speed is effectively increased, the production efficiency of the shoes is improved, and the degree of tightness of shoelace threading is effectively ensured.

Owner:苏州辰戈电子科技有限公司

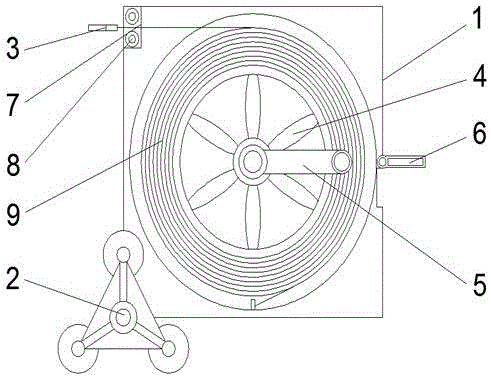

Electric power pipeline threading apparatus

InactiveCN106505483AEasy to cleanEasily brokenApparatus for laying cablesEngineeringMechanical engineering

The invention discloses an electric power pipeline threading apparatus. The threading apparatus comprises a main body, a triangle wheel and a rotation probe. The main body is provided with a wire spool, a crank, a handle and an incoming line and outgoing line port. The triangle wheel is arranged below a front end of the main body. The rotation probe is connected to one end of a pull wire through a bolt. The rotation probe is provided with a fried dough twist rod and a drill bit. The fried dough twist rod is arranged at a front end of the rotation probe. The drill bit sleeves an outer side of the rotation probe. The drill bit is provided with a fried dough twist rod sleeve and a spring. The fried dough twist rod sleeve is arranged in the drill bit. The fried dough twist rod sleeve sleeves the fried dough twist rod. The spring is arranged between the fried dough twist rod sleeve and the rotation probe. The spring sleeves the fried dough twist rod. In the invention, operation is simple; the threading apparatus can be moved conveniently, which is good for construction personnel to clean and crush plugs in a threading pipeline; and work efficiency is increased.

Owner:枣庄度秘信息科技有限公司

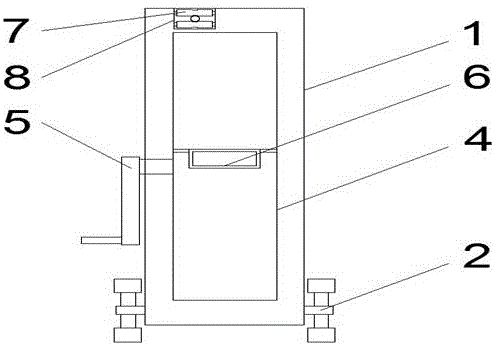

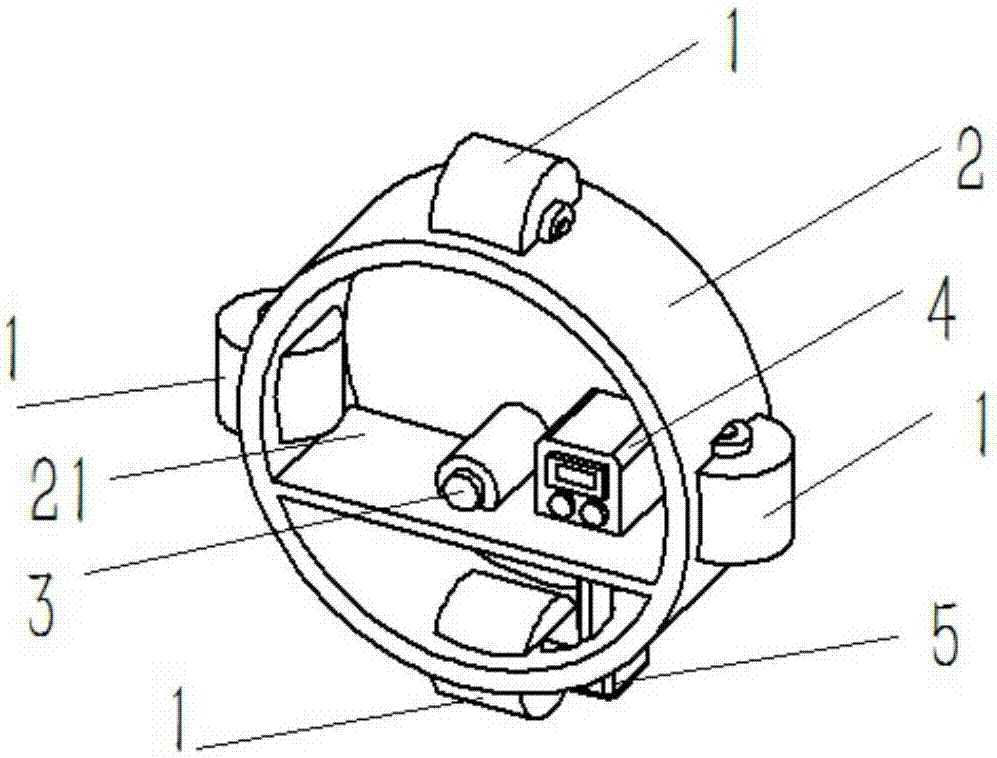

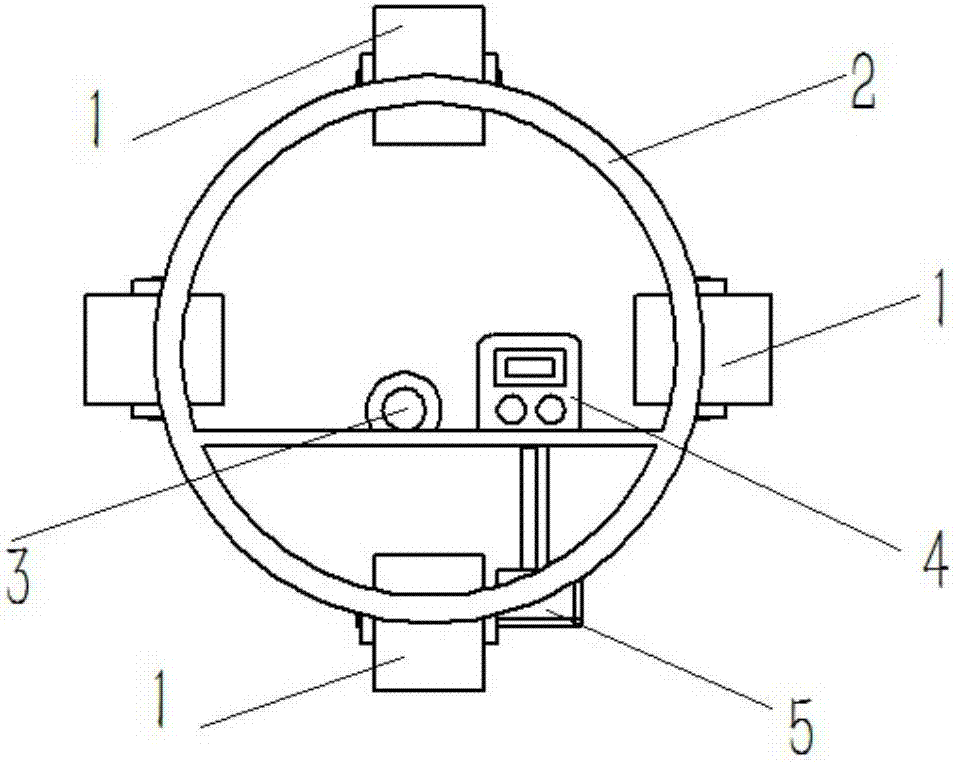

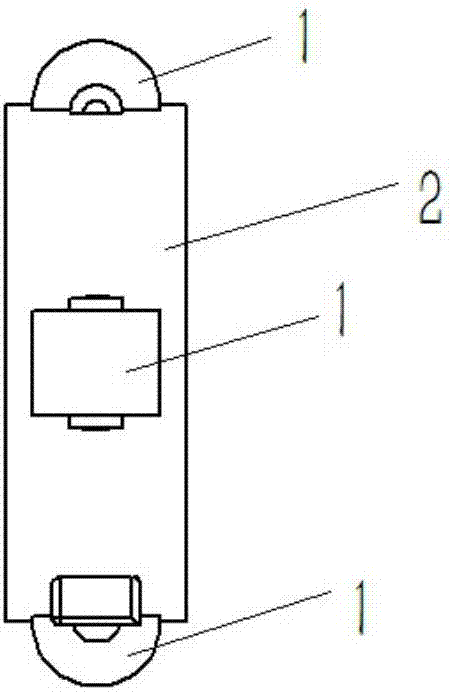

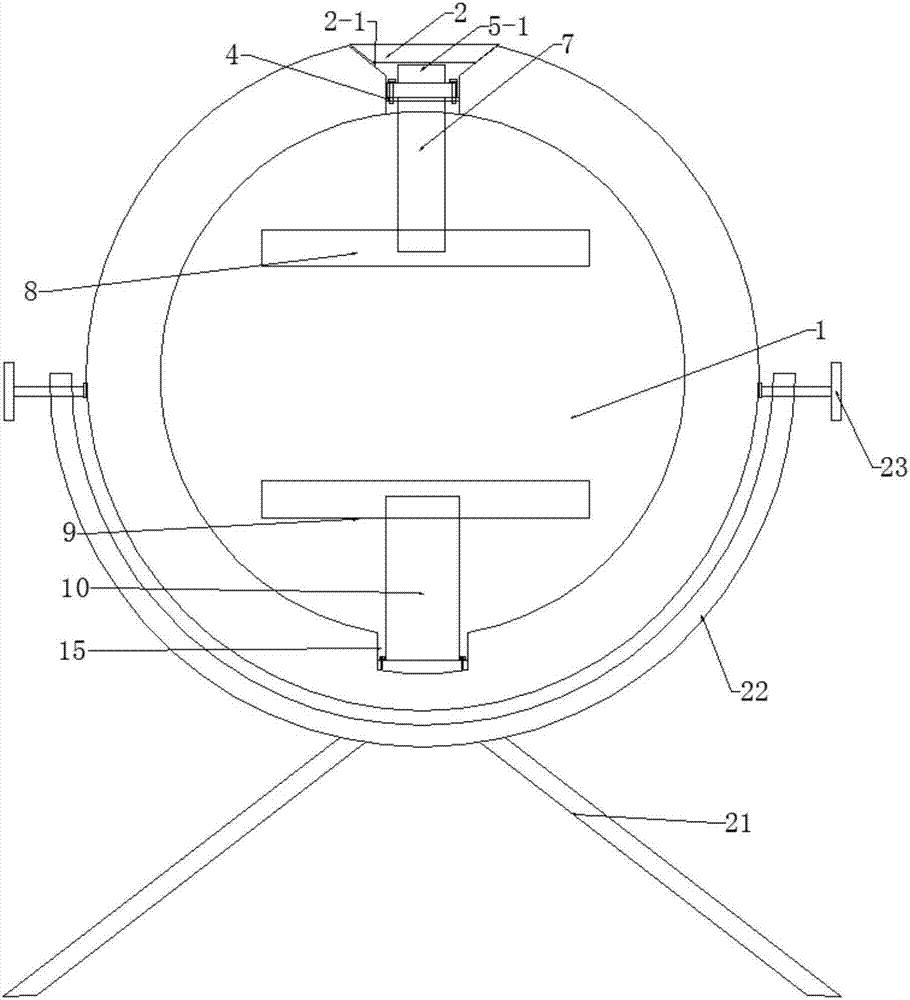

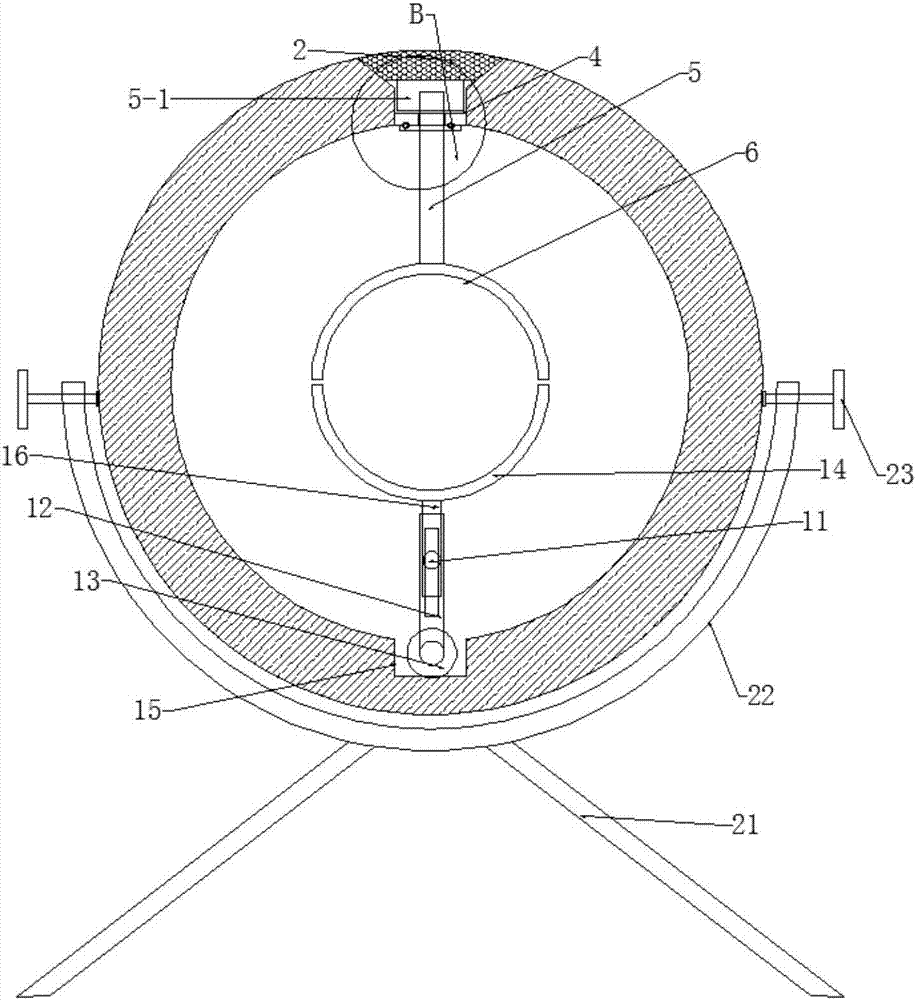

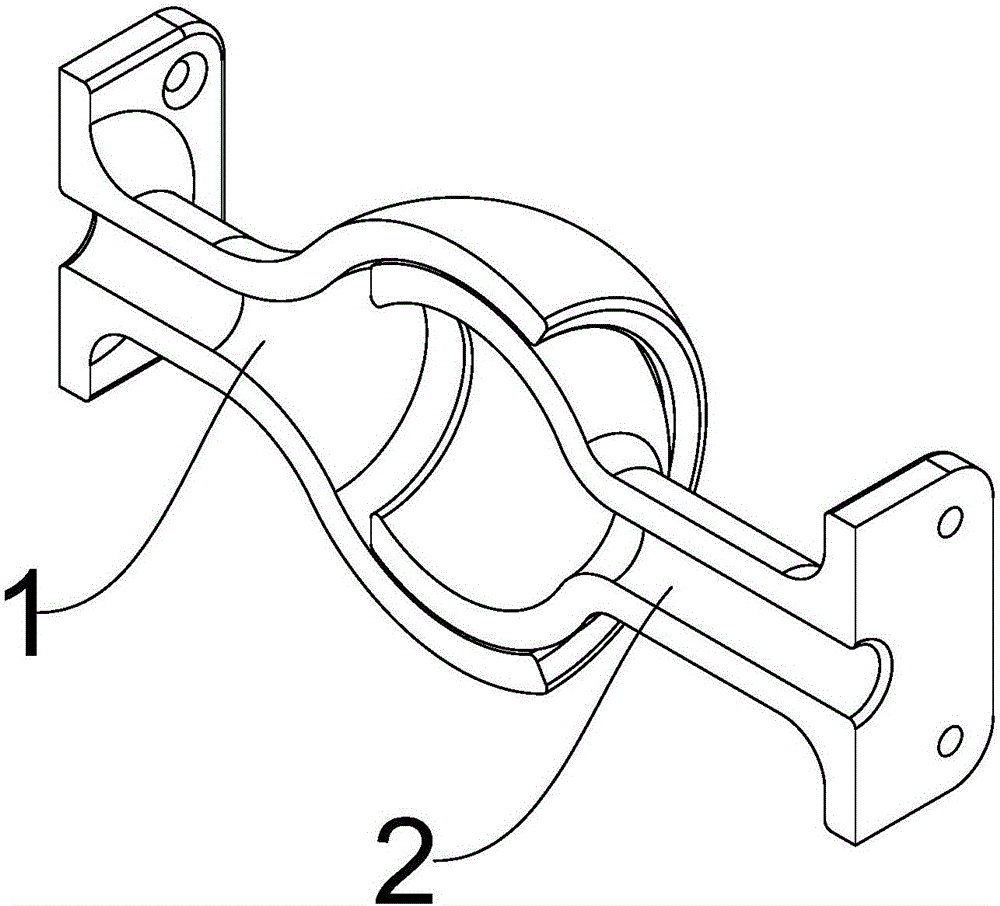

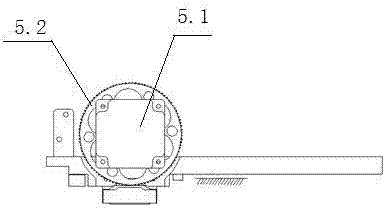

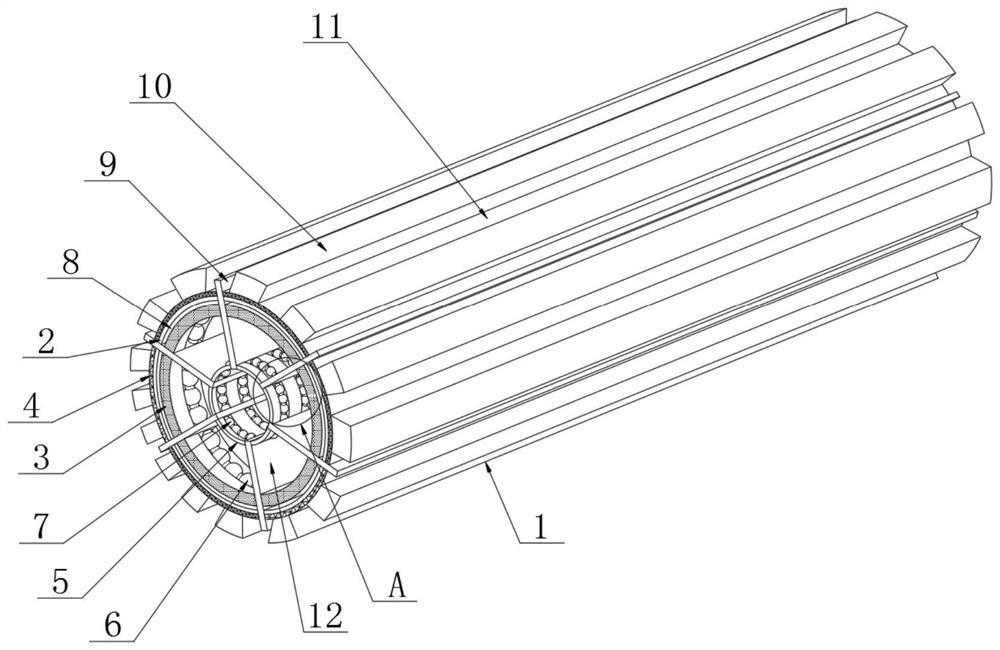

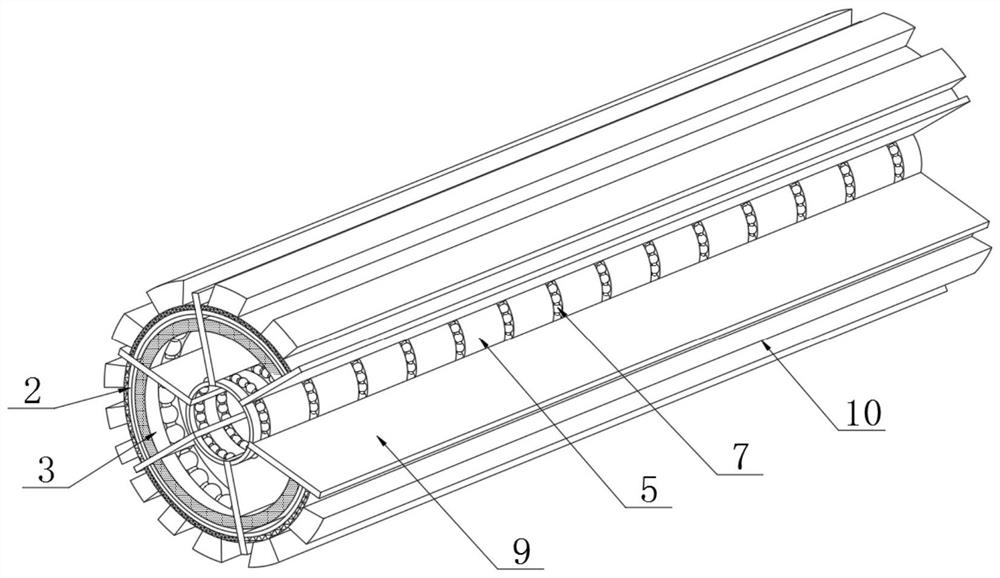

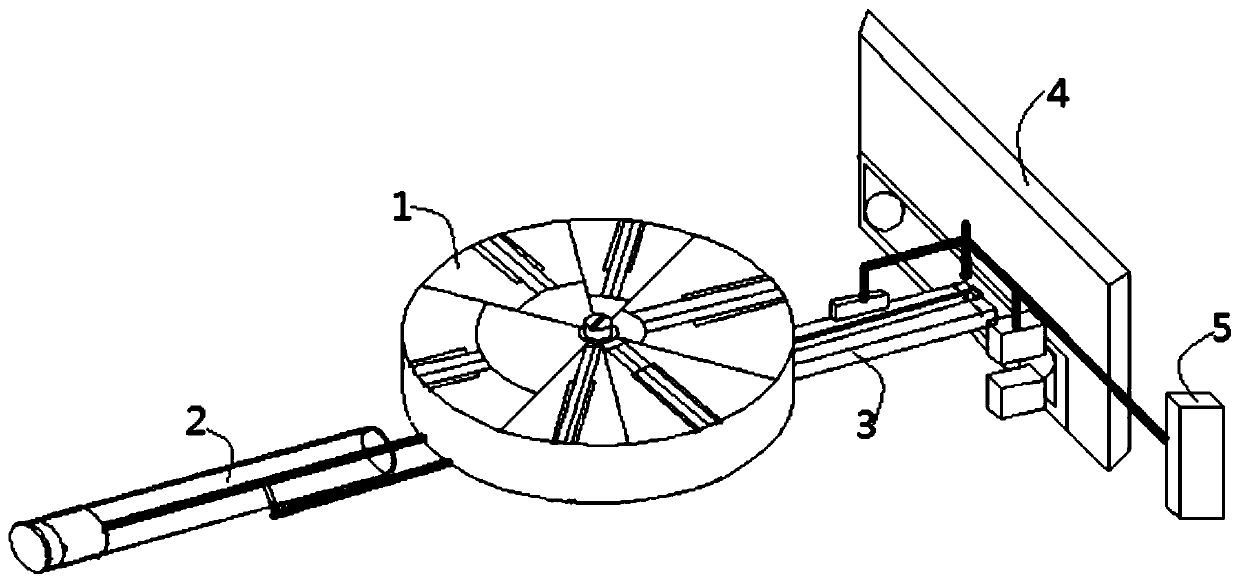

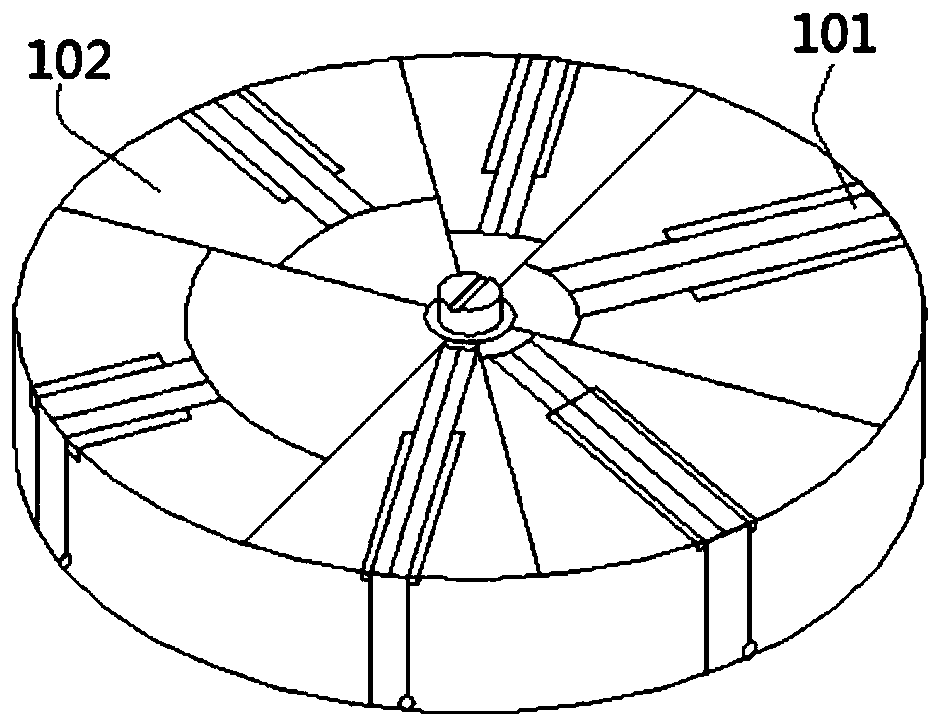

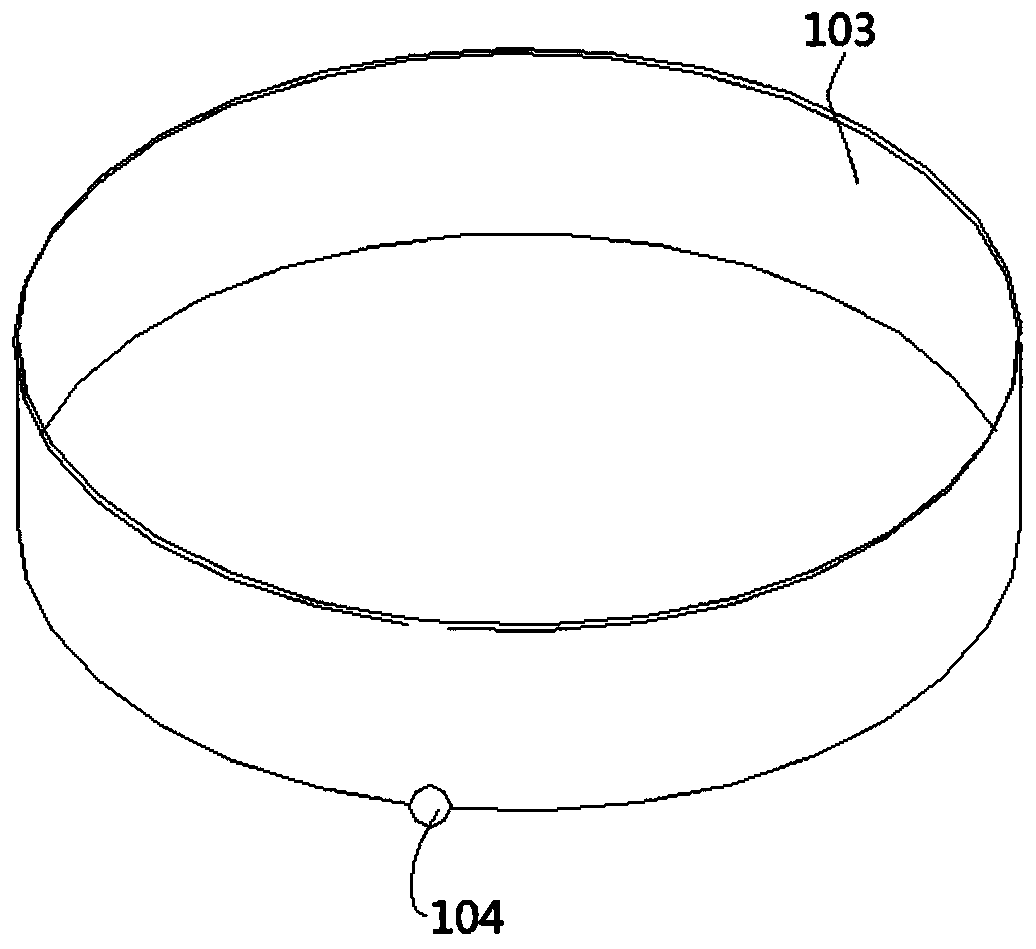

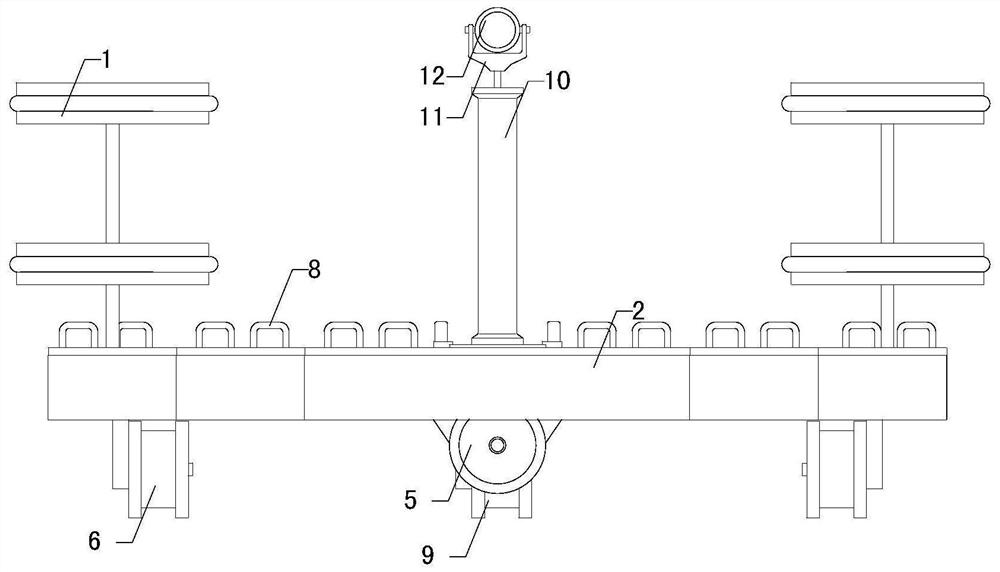

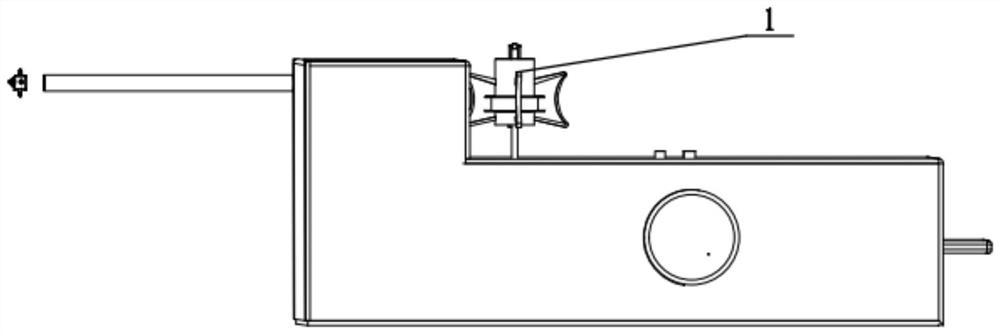

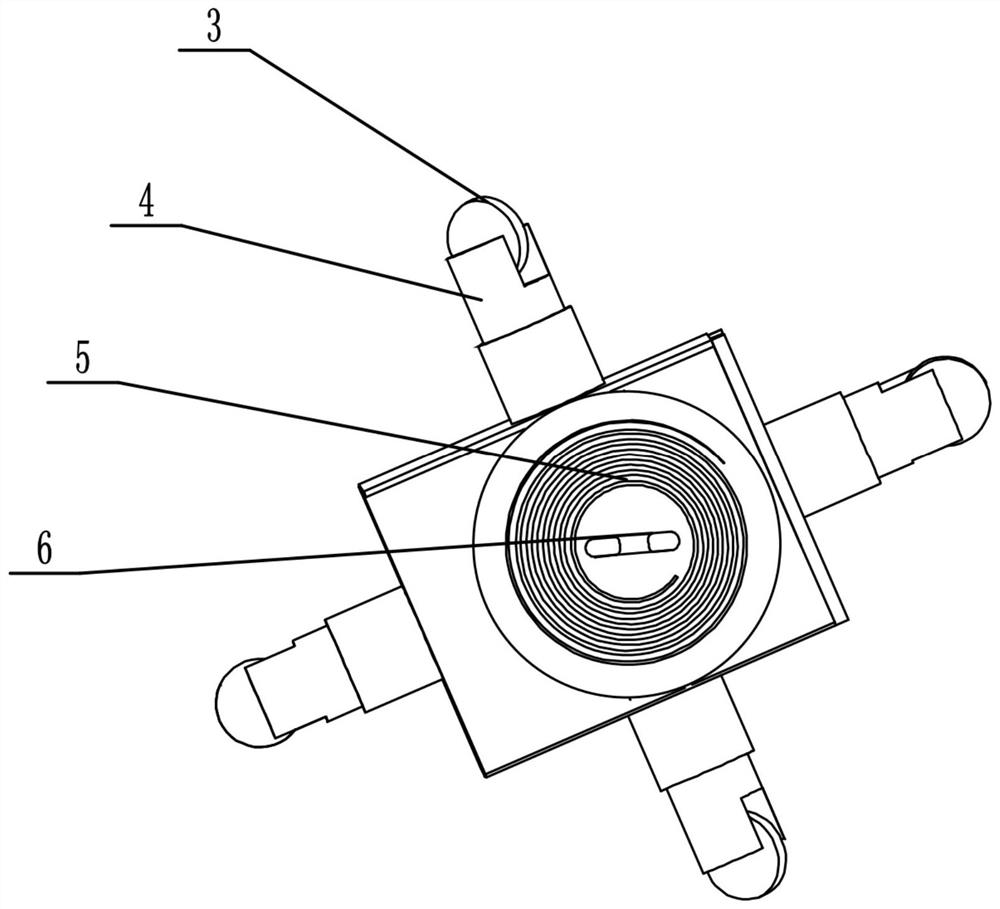

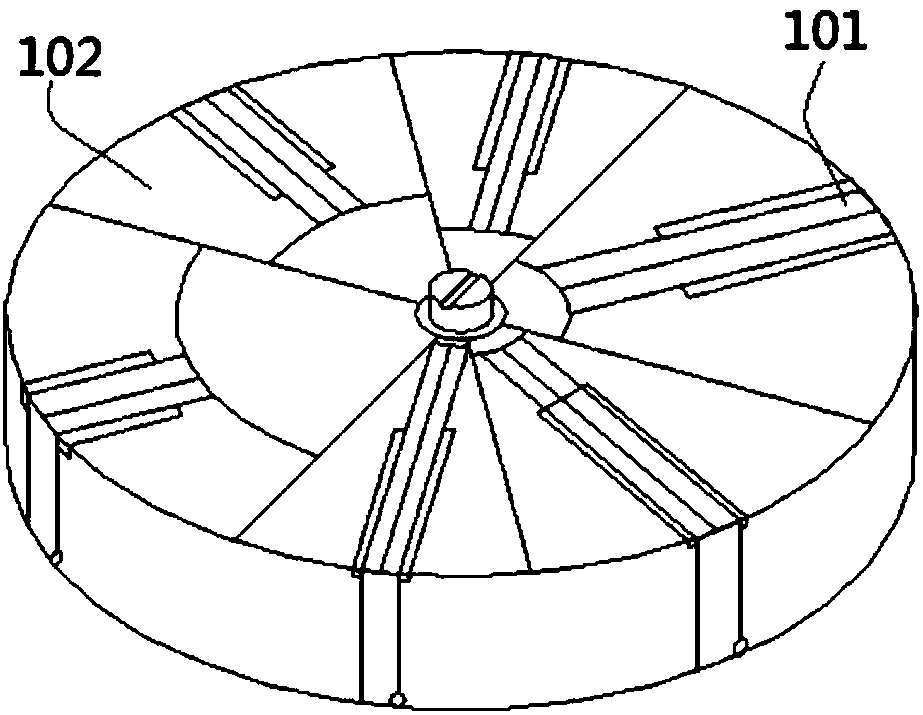

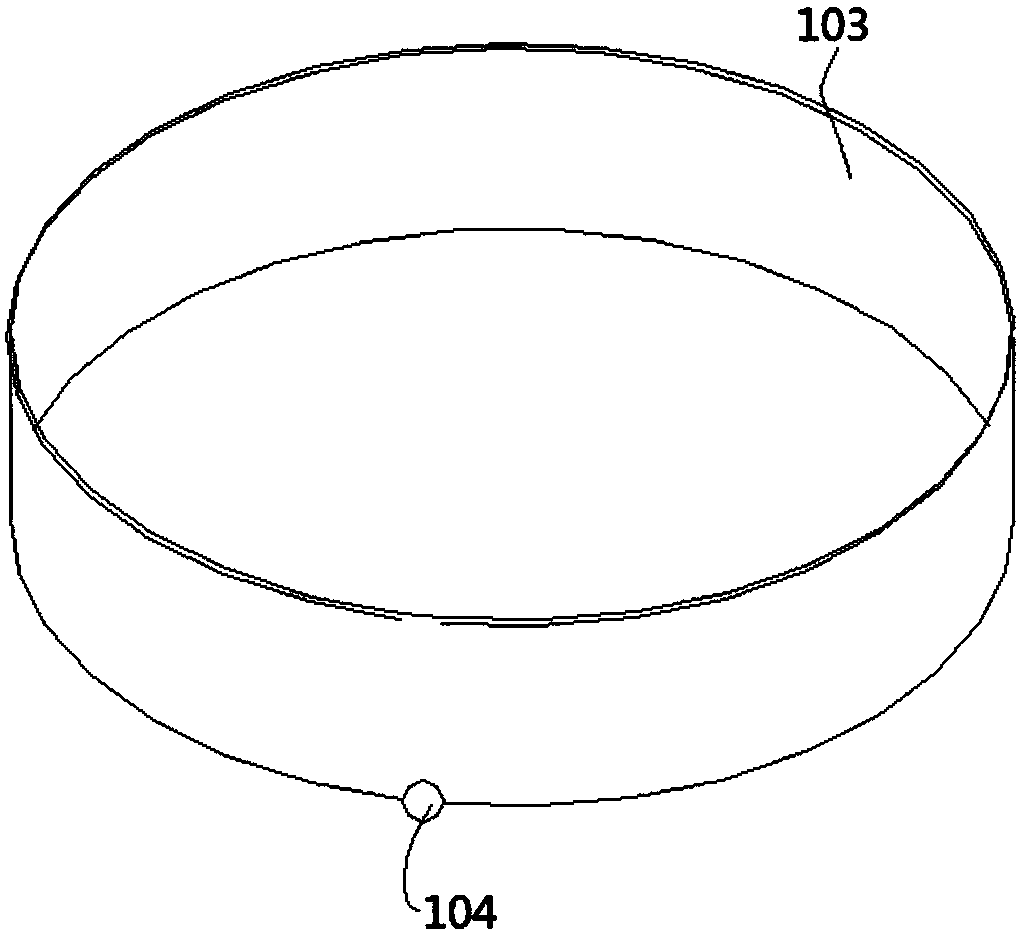

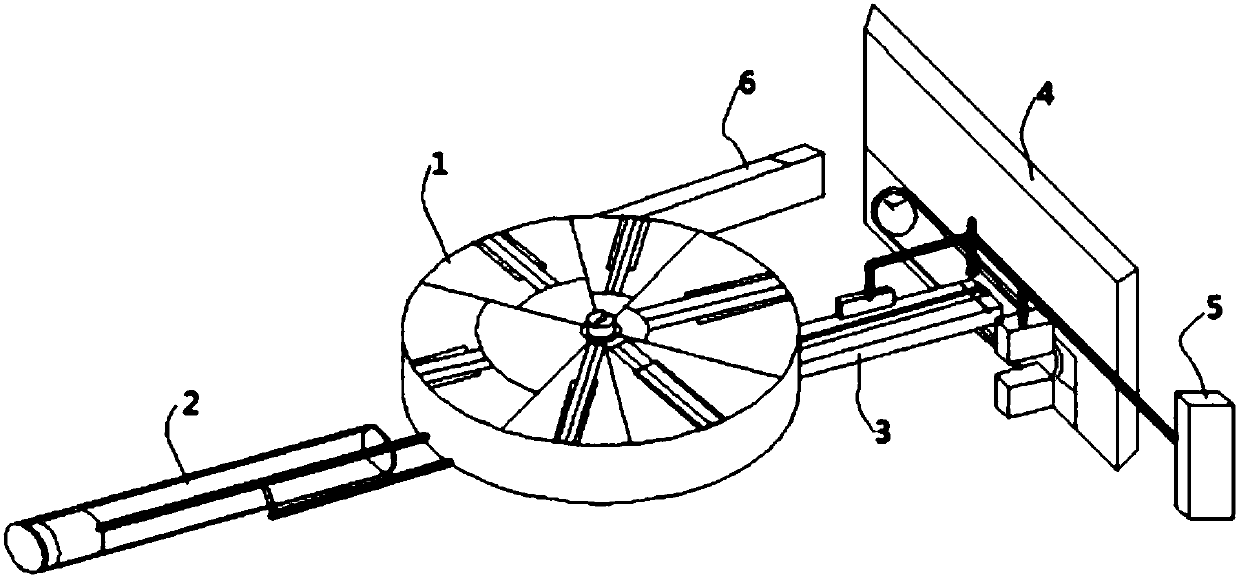

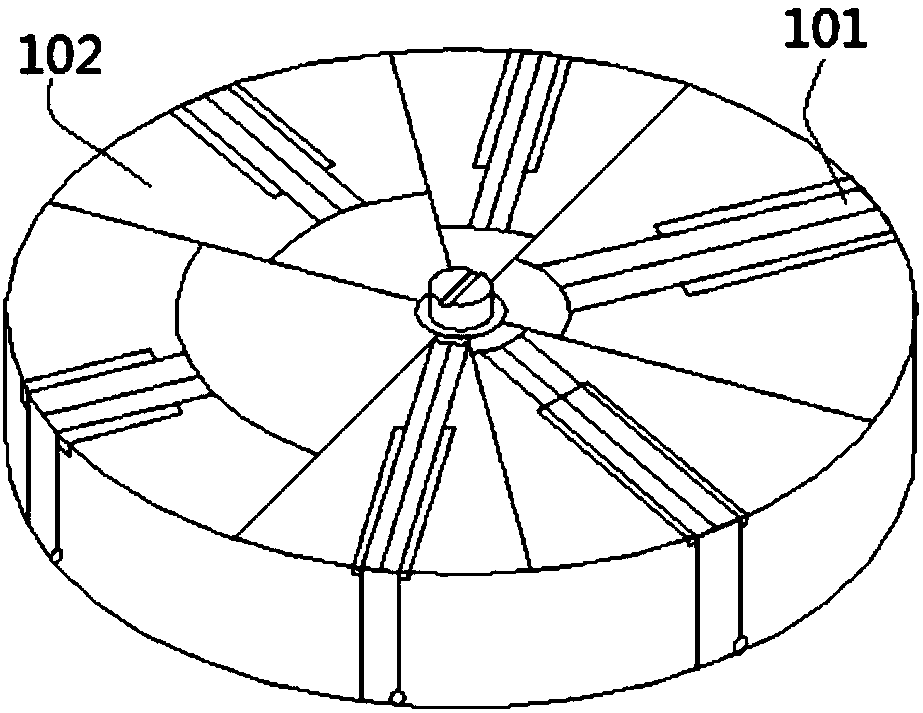

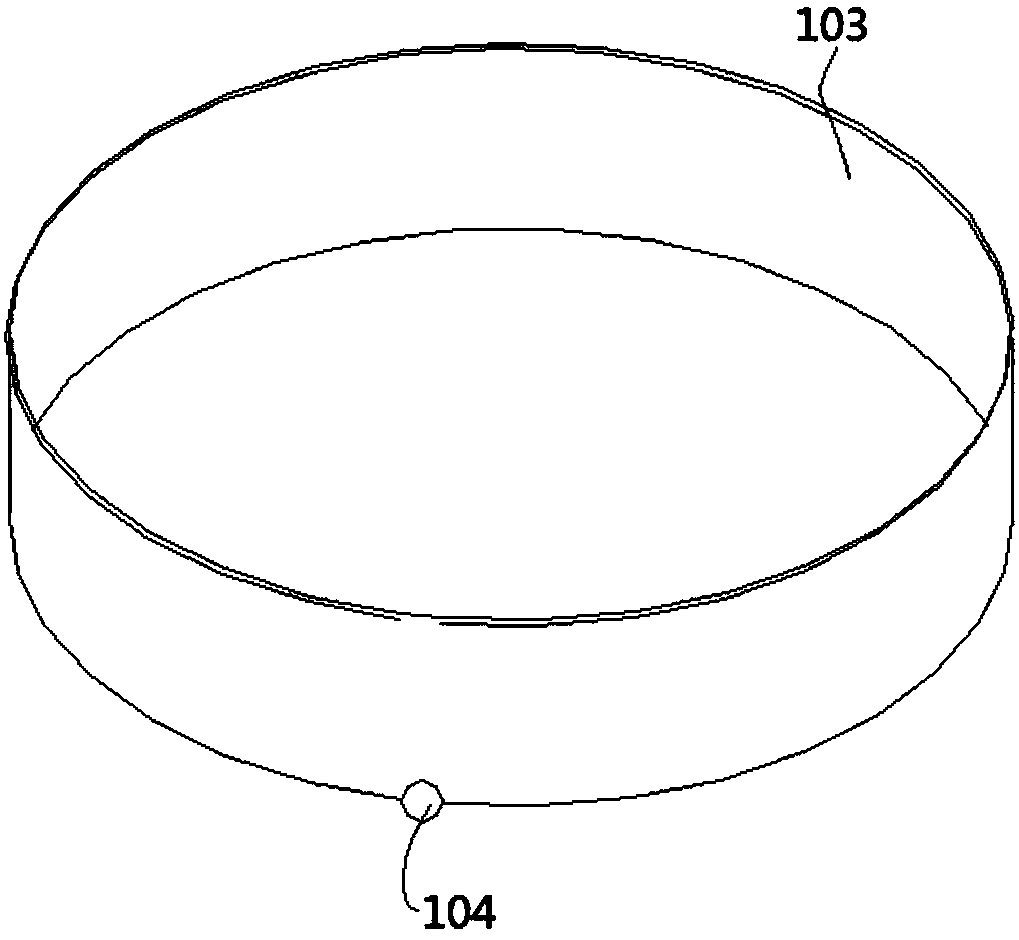

Rapid cable laying device

PendingCN107425483AFast threading speedHigh degree of automationApparatus for laying cablesFour-slidePetroleum engineering

The invention provides a rapid cable laying device, which comprises a circular shell (2), a cable fixing clamp (3) and a driving device, and is characterized in that the side wall of the circular shell (2) is provided with four rotatable sliding wheels (1), the four sliding wheels (1) are evenly distributed on the side wall of the circular shell (2), the cable fixing clamp (3) is fixedly connected inside the circular shell (2), and the driving device is rotatably connected with at least one of the sliding wheels (1). The rapid cable laying device is used in combination with the circular shell 2, the sliding wheels 1, the cable fixing clamp 3 and the driving device. The rapid cable laying device can slide in a pipe to be threaded automatically so as to complete an operation of threading a wire into the pipe automatically, and has the advantages of ability of not restricted by the length of the pipe, high threading speed and high automation degree.

Owner:TIANJIN DAILY PROSPERITY SCI & TECH GROUP

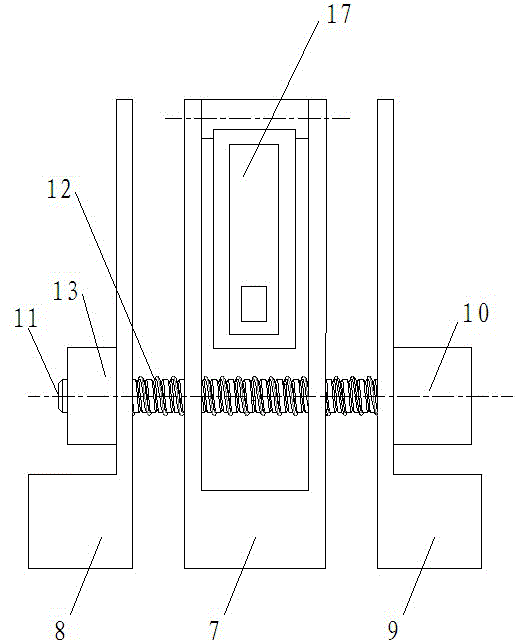

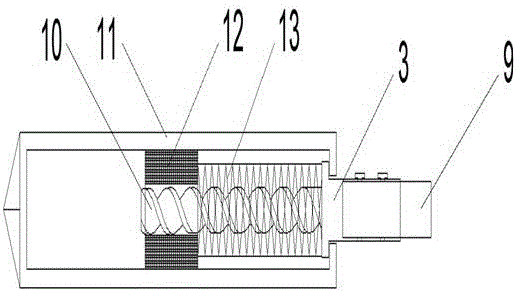

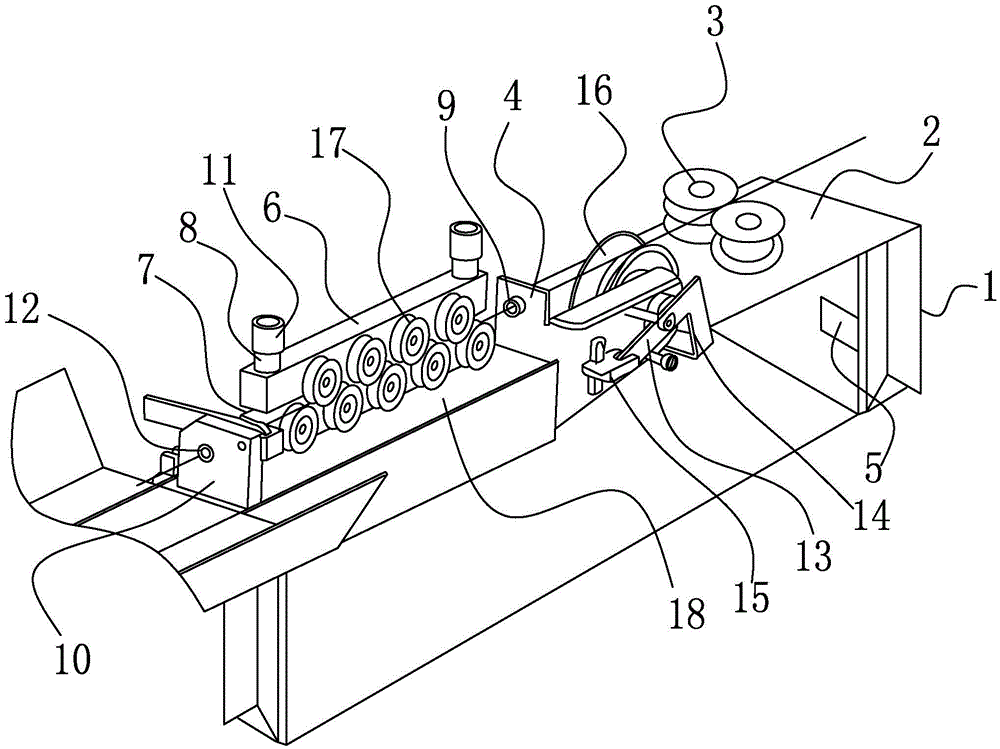

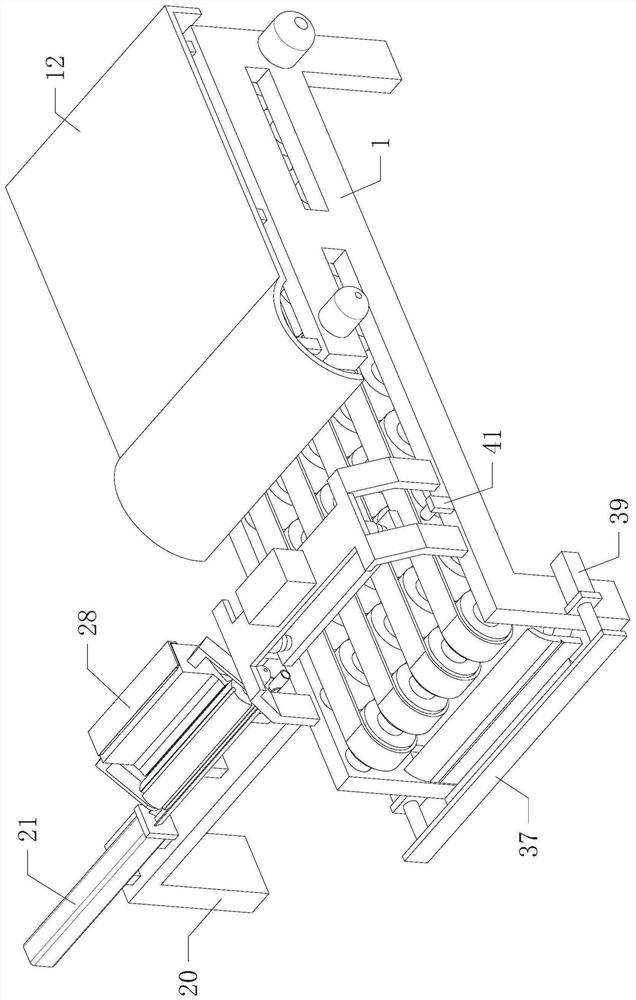

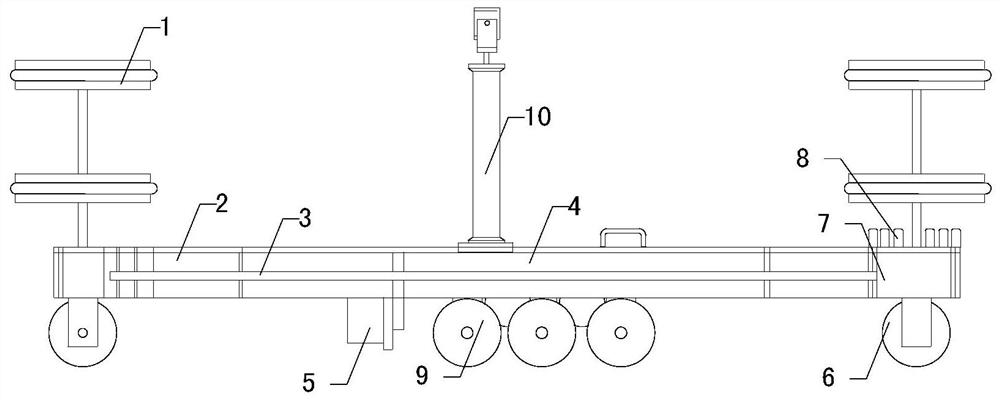

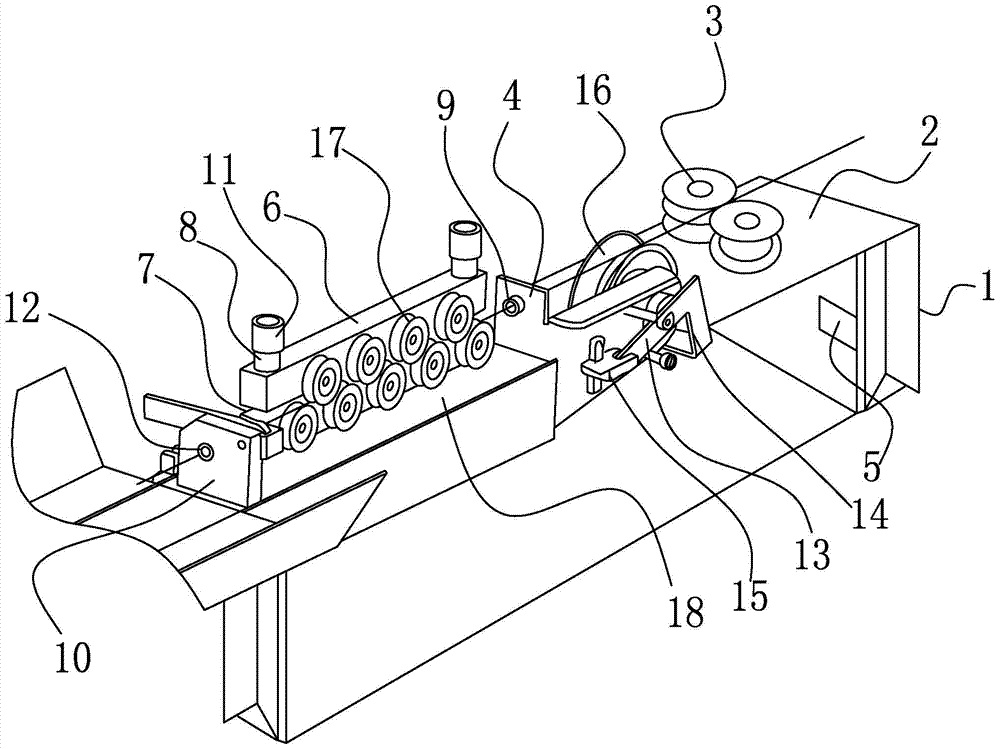

Wire feeding device for multi-functional terminal machine

InactiveCN105470777ARealize transmissionEasy to operateLine/current collector detailsDrive wheelEngineering

The invention relates to a wire feeding device for a multi-functional terminal machine. The wire feeding device comprises a support frame (1), a wire feeding plate (2) and a correcting plate (18), wherein the wire feeding plate (2) is arranged on the support frame (1); a wire feeding wheel device is arranged between the wire feeding plate (2) and the correcting plate (18); the wire feeding plate (2) is provided with a pair of wire feeding wheels (3) and a motor (5); the motor (5) drives the pair of wire feeding wheels (3) to synchronously rotate oppositely; the motor (5) is arranged on the support frame (1); the wire feeding wheel device comprises a guide plate (4), a driven wheel (16) and an adjusting device; the adjusting device is used for adjusting the driven wheel (16); the guide plate (4) is provided with a guide pipe (9); and the guide pipe (9) corresponds to the center of the upper end of the driven wheel (16). Through coordination of the wire feeding wheel device and the wire feeding wheels, when an electric wire penetrates between the pair of wire feeding wheels, the driven wheel 16 and the wire feeding wheels can be always propped against the electric wire when working by adjusting the driven wheel 16, so that transmission of the electric wire can be relatively stably achieved.

Owner:平湖市诚成电子科技有限公司

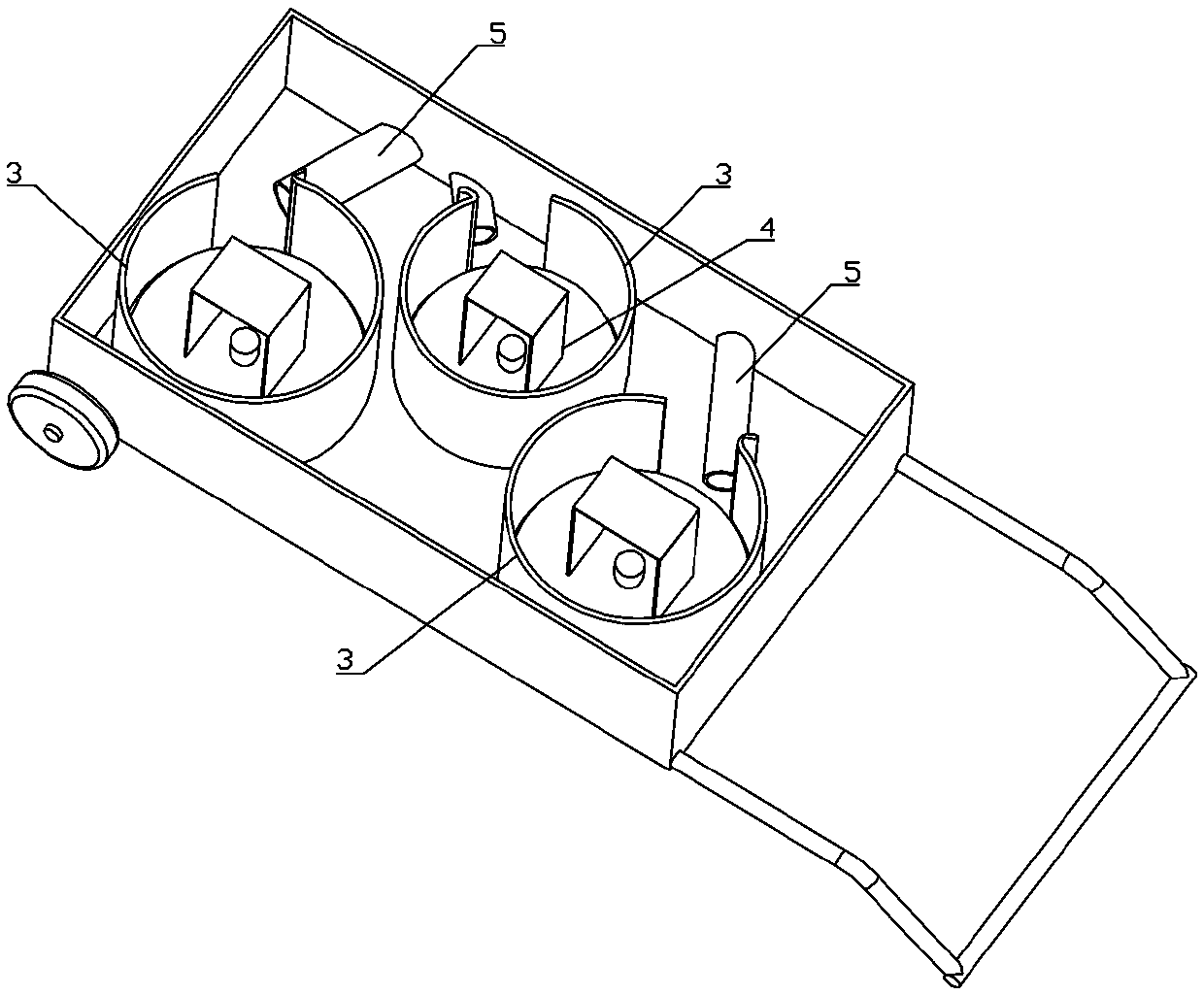

Movable and convenient pay-off box and pay-off method thereof

PendingCN109775431ASimple and efficient operationSave human resourcesFilament handlingEngineeringMechanical engineering

The invention relates to the technical field of pipe wire pay-off and discloses a movable and convenient pay-off box and a pay-off method thereof. The movable and convenient pay-off box comprises a mounting box and a pay-off device; the pay-off device is arranged in the mounting box; the mounting box is a box body; the top end of the box body is opened; rollers are mounted at the bottom of the boxbody; the pay-off device comprises cylindrical fences and locating shaft pieces; the locating shaft pieces are rotationally mounted in the cylindrical fences; the cylindrical fences are arranged on abottom plate in a manner of being perpendicular to the bottom plate of the mounting box; wire outlets are formed in the side walls of the cylindrical fences; wire outlet pipes are arranged outside the wire outlets; and the other ends of the wire outlet pipes penetrate out of the side surface of the mounting box. The wire penetrating speed is effectively increased, the pipe penetrating time of wires during decoration construction is shortened, the construction period is reduced, and the purposes that the production speed is increased, the labor quantity is reduced, and the production efficiency is improved are achieved.

Owner:BEIJING UNI CONSTR GRP CO LTD THIRD DEV & CONSTR CO LTD

Technique of thrilling through fire lighter for firecracker

A direct-through technique of lead wire on sparkler includes sticking a numbers of sparkler cylinders together to form positive polygonal set body of sparkler, opening hole and setting lead wire then pushing up said lead wire in cylinder to be convex form, packing soil and using press shaft with concave center to press soil tightly, exposing top of convex form lead wire of sparkler above soil surface and contacting said lead wire with gunpowder to be packed late on.

Owner:刘志娟

Industrial simple wire harness threading device

ActiveCN107171253APlay a protective effectExtended useful lifeApparatus for laying cablesEngineeringCable harness

The invention discloses an industrial simple wire harness threading device and relates to the technical field of wire harness. The device comprises a supporting positioning rack and a hard sleeve pipe. The supporting positioning rack comprises supporting feet, a C-type support plate and adjusting bolts. A threading guidance device and a threading adjusting device are arranged in the sleeve pipe. A V-type groove is arranged in the outer wall of the sleeve pipe. A sealing strip is clamped in the V-type groove. An upper strip-shaped slide groove is arranged in the bottom of the V-type groove. The threading guidance device comprises a left guidance device and a right guidance device which are symmetrically installed on the inner wall of the sleeve pipe. The guidance device comprises an upper press wheel and a lower press wheel. According to the invention, the threading device achieves precise positioning; the threading speed is quick; the threading device works without special skills; threading speed is improved; a protection function is well achieved for wire harnesses; practical service lifetime of the wire harnesses is extended; and maintenance cost is reduced.

Owner:WUHU BOKANG ELECTRICAL

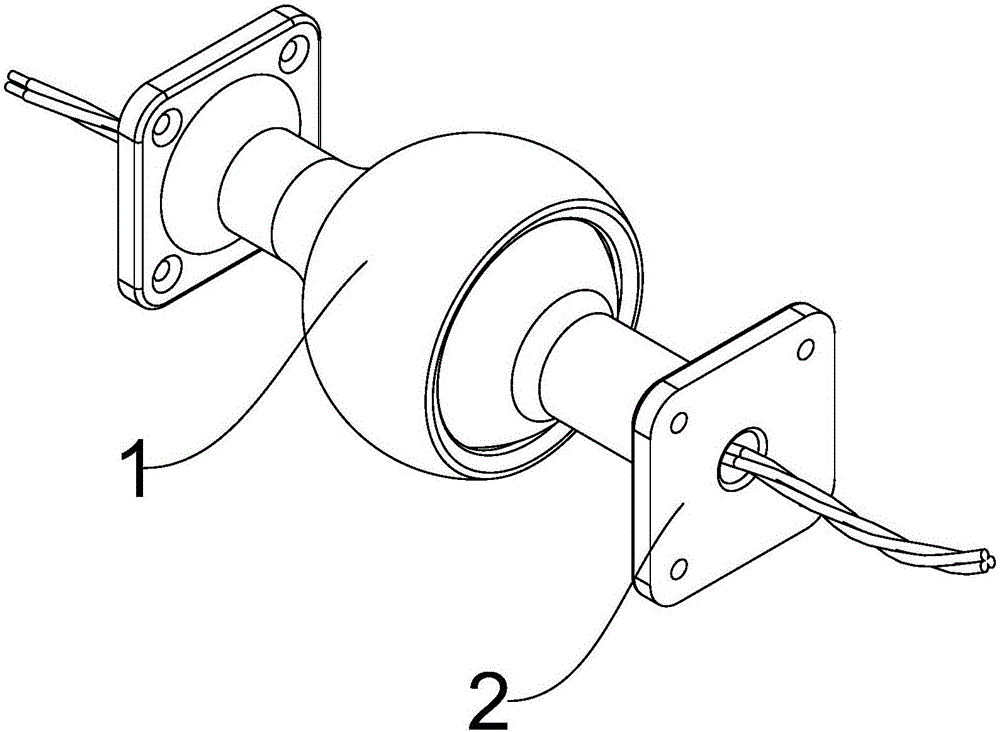

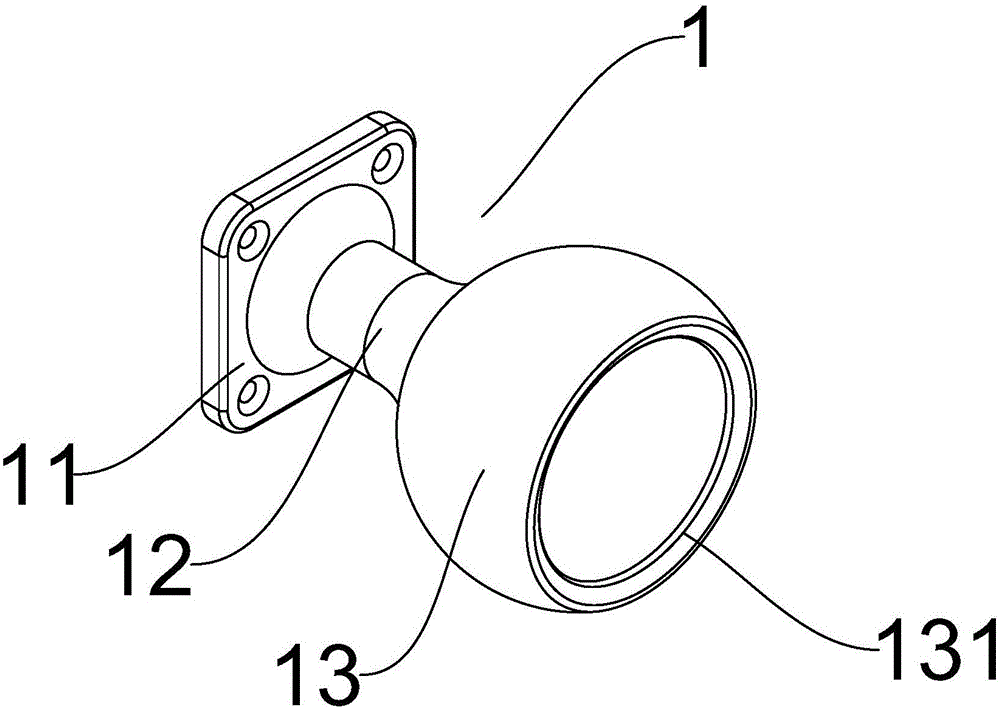

Hinge allowing wire to pass through

InactiveCN104993431ANot easy to bend repeatedlyExtended service lifeCable arrangements between relatively-moving partsPivotal connectionsOpen structurePower transmission

The invention discloses a hinge allowing wires to pass through. The hinge allowing wires to pass through comprises a first connecting portion and a second connecting portion, wherein the first connecting portion comprises a first hinge body, a first connecting pipe and a first spherical shell, one end of the first connecting pipe is vertically connected with the center of the first hinge body, the other end is connected with one side of the first spherical shell, the other side of the first spherical shell is of an open structure, and a first connecting hole is formed in the other side of the first spherical shell; and the second connecting portion comprises a second hinge body, a second connecting pipe and a second spherical shell. The hinge allowing wires to pass through has the advantages that: the size of a wire passing space is large, wires with large diameter can pass through the wire passing space, thus the hinge allows power transmission lines with high power to pass through; and the wire passing operation is simple, the wire passing speed is fast, the wires passing through the hinge can be protected against damage, the same portion is not liable to bend repeatedly, and the service life of the wires passing through the hinge is long.

Owner:季德贵

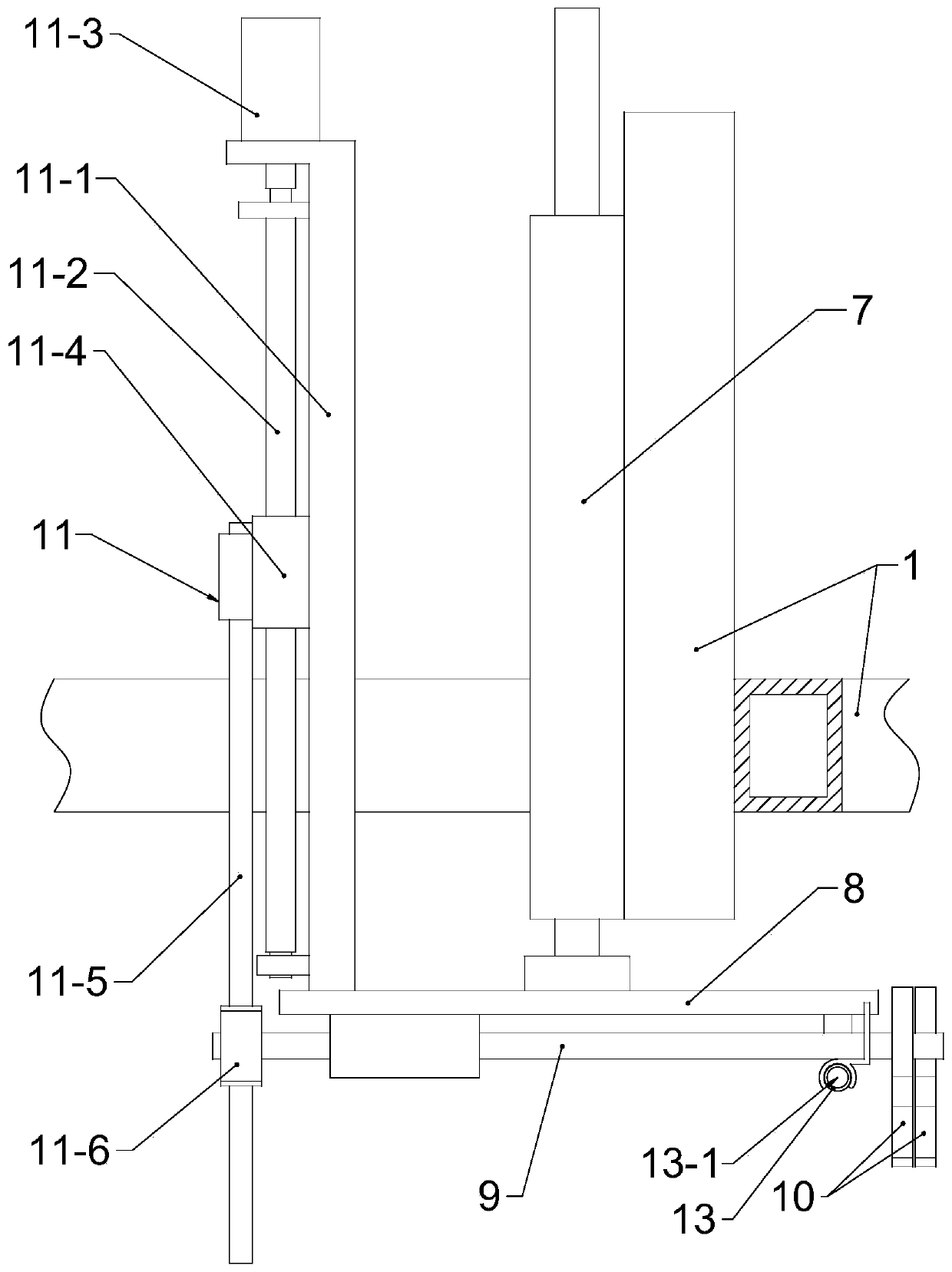

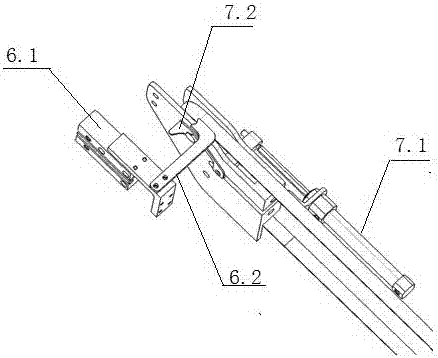

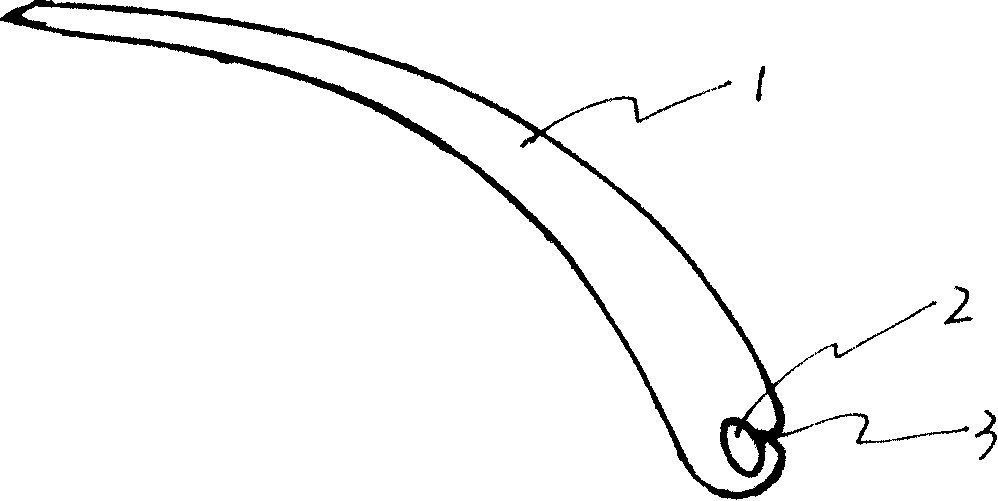

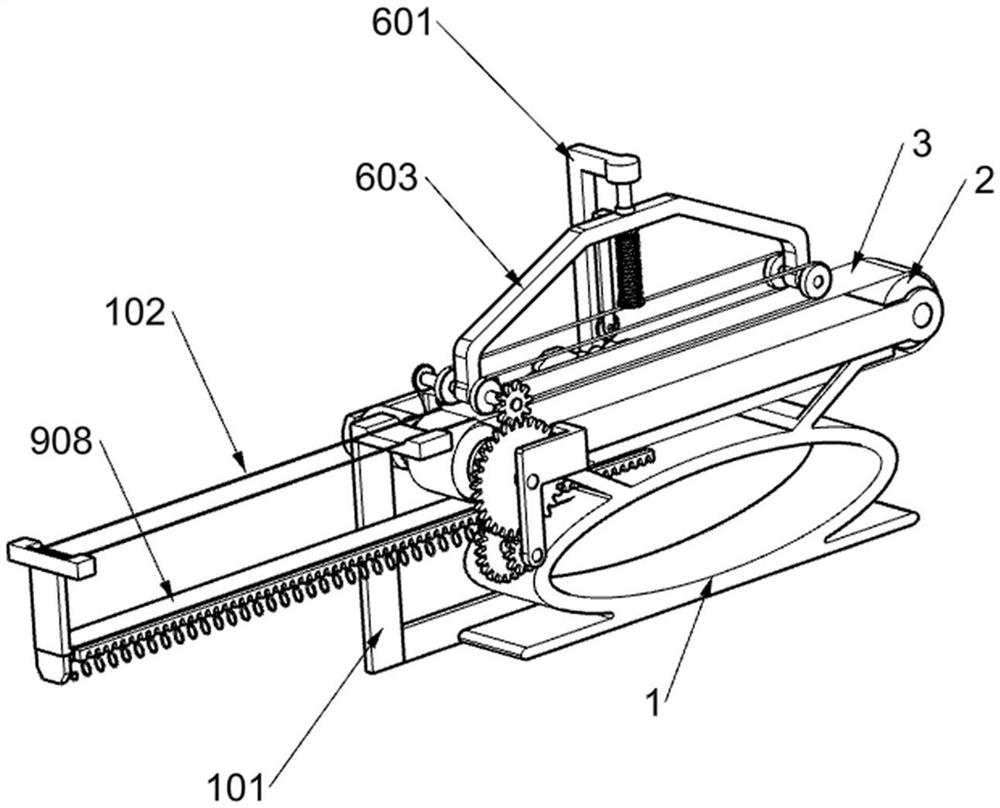

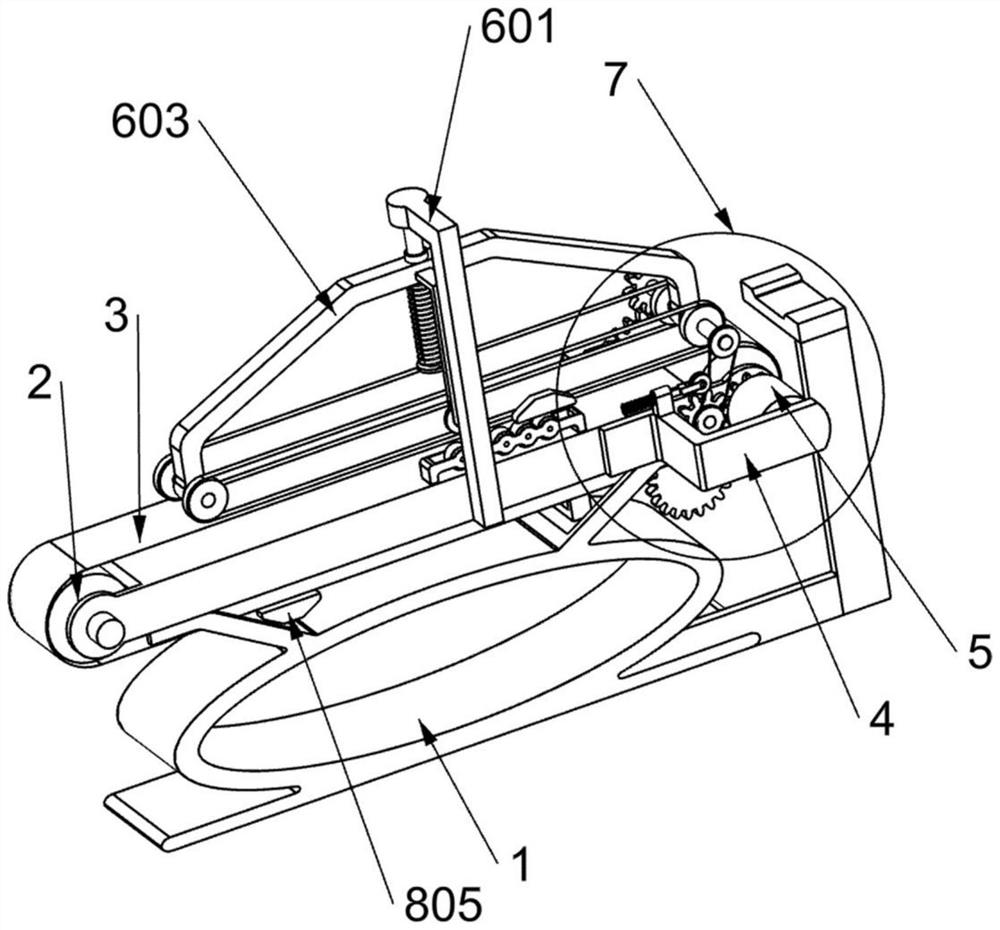

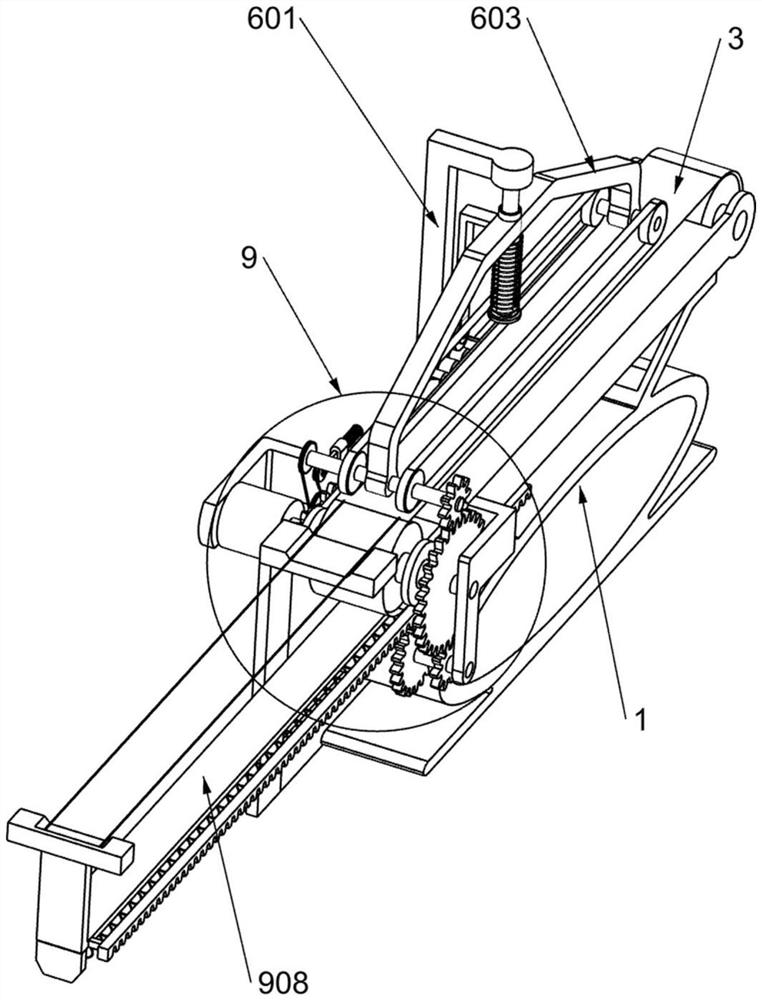

Automatic arrow belt threading mechanism

ActiveCN106012252BReduce labor intensityReduce labor costsAuxillary apparatusYarnReciprocating motion

The invention relates to an automatic arrow belt drafting mechanism which comprises an arrow belt and an arrow belt groove. The head of the arrow belt is provided with an arrow hook for hooking single yarn fed by a weft storage device, and the tail of the arrow belt is located in an arrow belt bag. The tail, in the arrow belt bag, of the arrow belt rapidly does straight reciprocating motion in the arrow belt groove under the effect of an arrow belt driving mechanism. The head of the arrow belt groove is provided with a heat yarn pressing device and a head yarn beating mechanism. The arrow belt groove is sequentially provided with four fractures. A harness wire, a yarn push mechanism, a reed and a yarn beating mechanism are sequentially arranged in the fractures respectively front head to tail. Single yarn fed by the weft storage device can rapidly and automatically penetrate through the harness wire and the reed in sequence at a time, the labor intensity is lowered, the labor cost is reduced, and working efficiency is improved.

Owner:JIANGYIN TONGYUAN TEXTILE MACHINERY

Efficient automatic threading method

ActiveCN107841837AImprove needle extraction efficiencyPush needle process is stableNeedle-threading devicesControl systemBiomedical engineering

The invention discloses an efficient automatic threading method, and belongs to the technical field of sewing threading. The specific process of the treading method includes the steps that a control system rotates a needed needle to the corresponding position of a first needle pushing rod, and the first needle pushing rod penetrates a rod penetrating hole, enters a needle pushing groove and pushesthe needle into a needle manipulation groove; a needle pushing slide block of a second needle pushing rod makes the needle move in the direction close to a thread pulling device in the needle manipulation groove, and the thread pulling device puts a thread in a thread groove through a thread pulling assembly on a caterpillar track to cover a needle hole; the connecting rod of a needle threading device drives the needle threading rod of a threading device to move downwards, a needle pressing block presses a needle body, and the needle threading rod continues to press downwards to complete thethreading process. The method achieves the automation of the whole process from needle storage to threading, it is not necessary to conduct manual needle putting and manual needle hole direction adjustment, and a needle storage device can display the number of needles, so that people can add needles into the needle storage device in time, and the needle threading efficiency is improved.

Owner:泰安博信能源设备有限公司

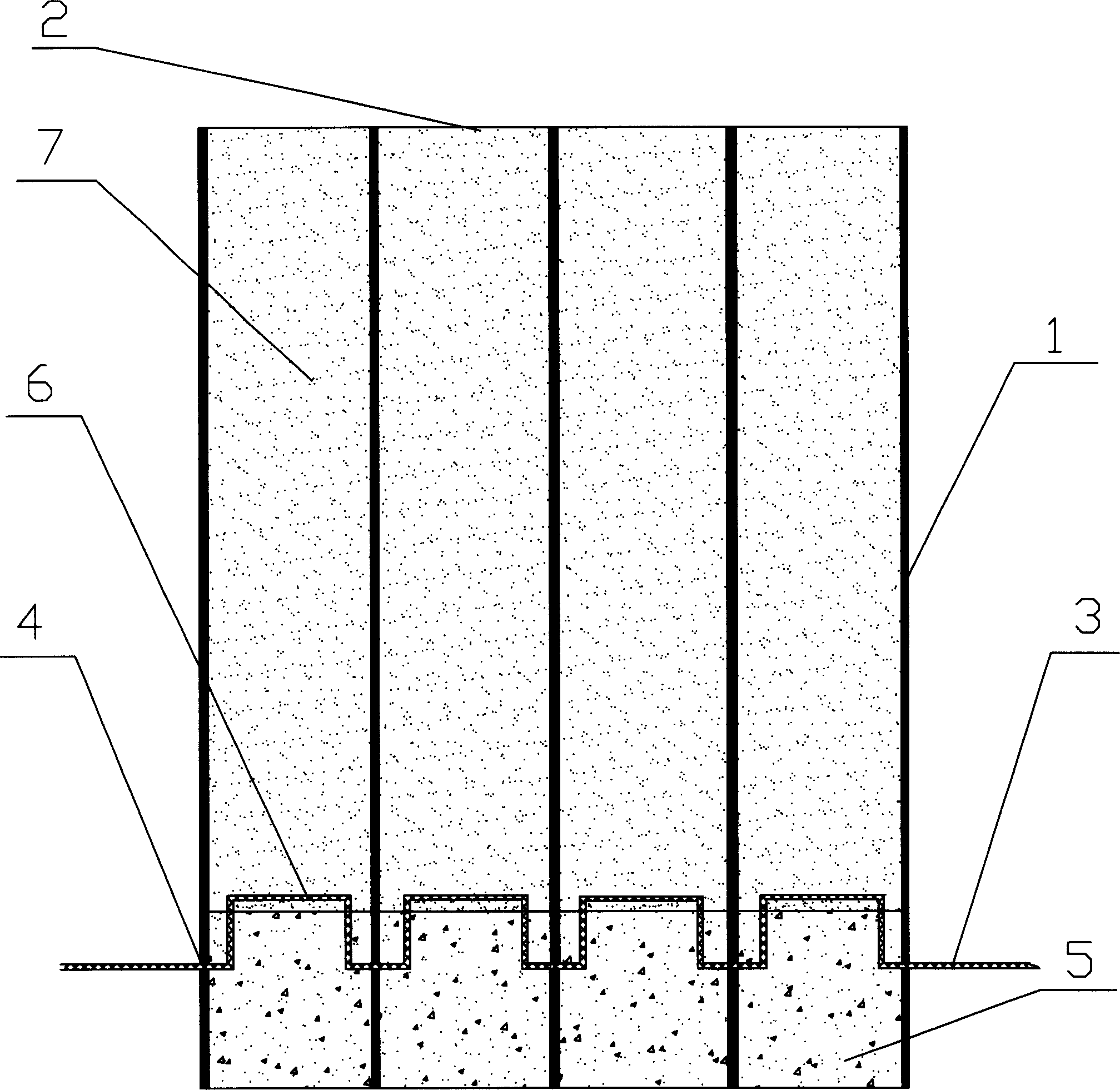

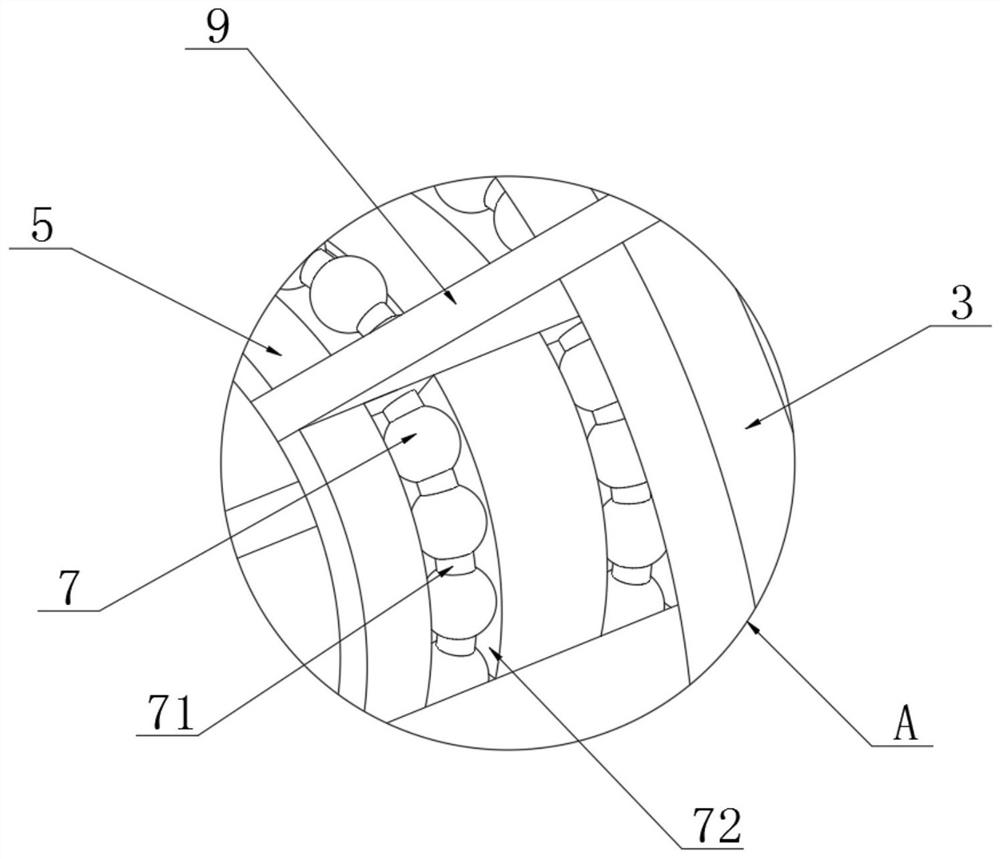

Heat-resistant and impact-resistant MPP electric power tube

ActiveCN112751306AImprove thermal conductivityIncreased durabilityCable installations in underground tubesHeat-exchange elementsThermodynamicsMechanical engineering

The invention relates to the technical field of electric power pipes, and discloses a heat-resistant and impact-resistant MPP electric power tube, which comprises a pipe tube, the tube body comprises an outer tube, an inner tube and a steel mesh layer, a filling cavity is arranged between the outer tube and the inner tube, the filling cavity is filled with a heat-conducting pressure-resistant material, and a plurality of pressure-resistant strips are distributed on the outer surface of the steel mesh layer at equal intervals. A center tube is arranged at the center of the inner side of the inner tube, a plurality of heat conduction plates are arranged on the outer side face of the center tube at equal intervals, a separation cavity is formed in the position, between every two heat conduction plates, of the inner side of the inner tube, and a plurality of sets of first balls are arranged on the position, in the separation cavities, of the inner side face of the inner tube at equal intervals. Multiple sets of second balls are annularly arranged on the surface of the center tube at equal intervals. The MPP electric power tube is high in heat conductivity and good in compression resistance, electric power cables can be separately placed, the problems that when a traditional MPP pipe is threaded, friction is caused between the electric power cables and the inner wall of the tube, and threading is strenuous and slow in speed are solved, and later cable replacement and maintenance are facilitated.

Owner:ANHUI LANTONG TECH CO LTD

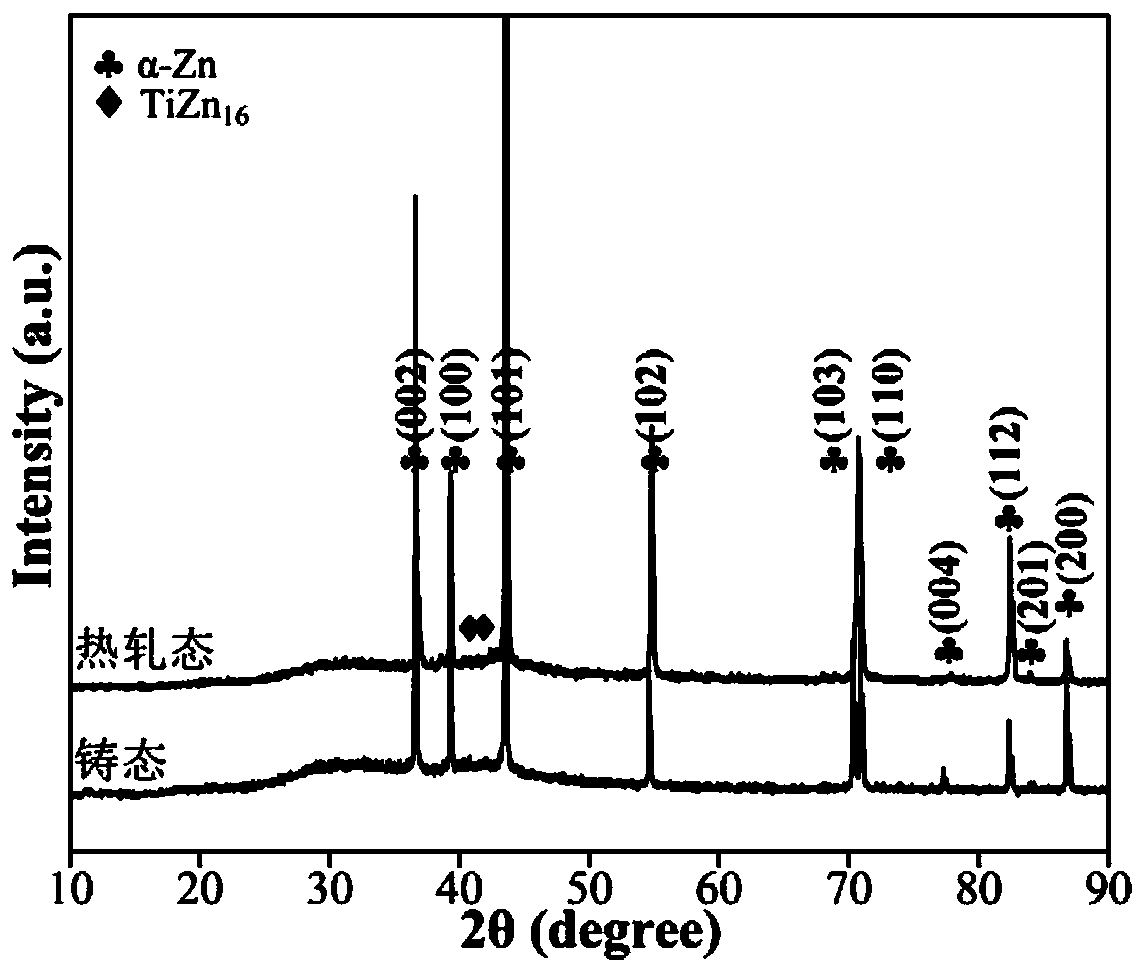

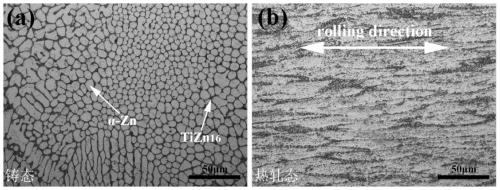

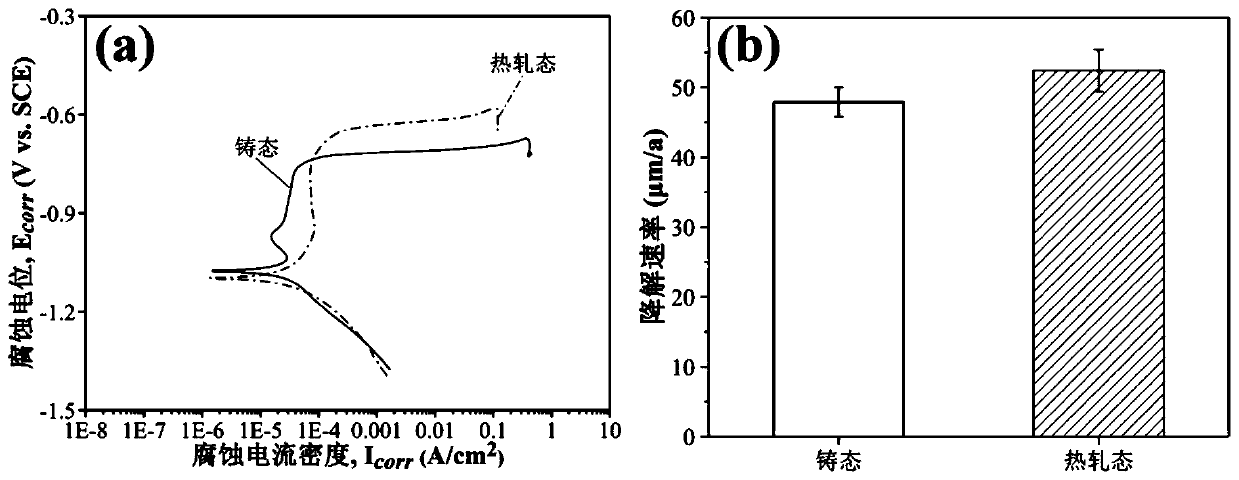

Degradable Zn-Ti binary biomedical material and preparation method thereof

InactiveCN111529761AReduce the temperatureTemperature drops too fastSurgeryPolymer scienceOrganic chemistry

Owner:ZHEJIANG IND & TRADE VACATIONAL COLLEGE

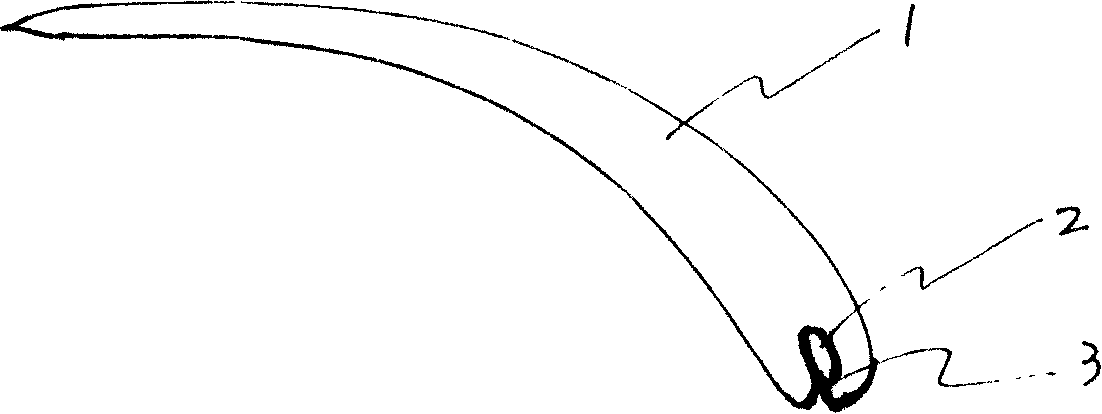

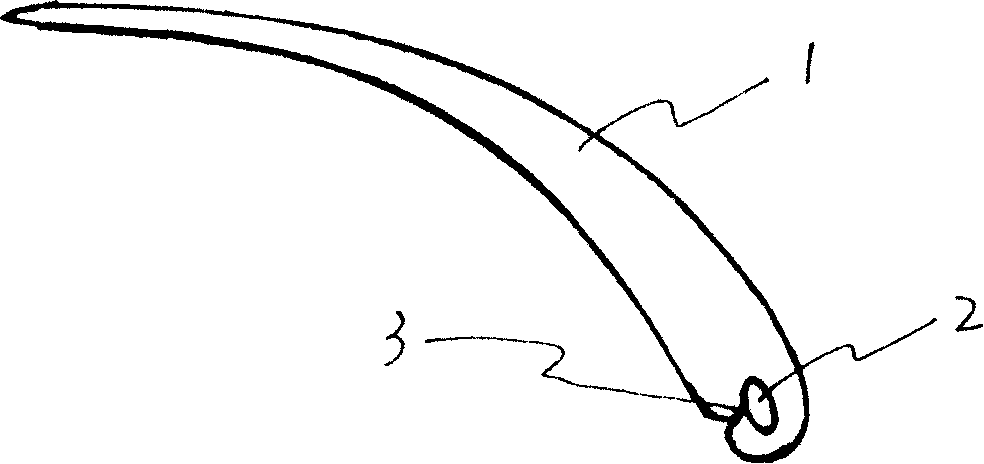

Operation sewing needle

InactiveCN101209213AFast threading speedGood effectSurgical needlesSurgical operationSurgical department

The invention discloses a surgical suture needle, which is provided with a needle body; the back end of the needle body is provided with a threading hole, and a threading slot is arranged between the threading hole and the outside of the needle body. The invention is suitable for the usage in the hospital surgical operations, more particularly, on a plurality of occasions where a plurality of small surgical suture needles are adopted for the major operations and the invention can significantly improve the threading speed and win the time for the operations.

Owner:李军

A high-efficiency automatic threading system

ActiveCN107841836BImprove needle extraction efficiencyPush needle process is stableNeedle-threading devicesComputer hardwareComputer architecture

The invention discloses an efficient automatic threading system, and belongs to the technical field of sewing threading. The system includes a needle storage device, a needle pushing device, a needlemanipulation device, a thread pulling device, a needle threading device and a control system; one side of the needle storage device is provided with the needle pushing device, and the other side is provided with the needle manipulation device; the end, away from the needle storage device, of the needle manipulation device is provided with the thread pulling device, and the needle threading deviceis arranged above the end, close to the thread pulling device, of the needle manipulation device; the control system controls all the devices of the automatic threading system to action. According tothe system, through coordination and cooperation of the control system and all the devices, automation of needle taking, thread pulling and needle threading is improved; a counting device is arranged,so that it is convenient for staff to know the number of remaining needles in a needle box and supplement needles in time; the speed of threading is increased, and the working efficiency is improved.

Owner:临沂经济开发区城市建设投资有限公司

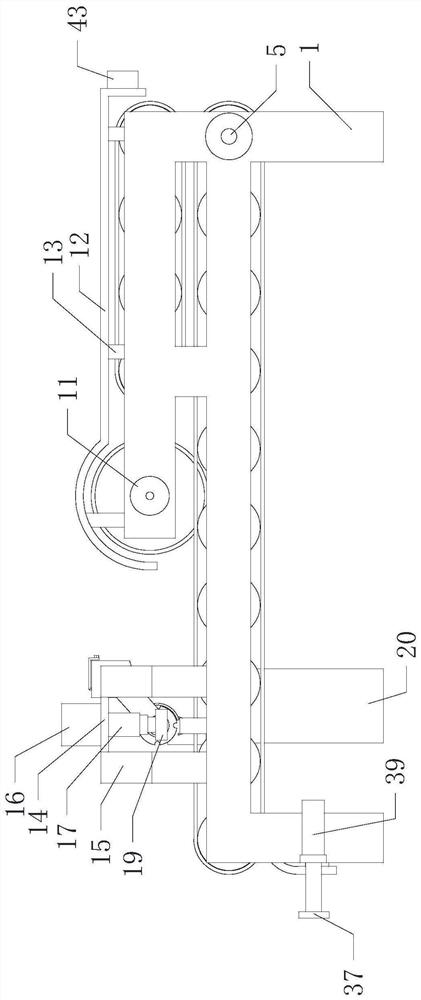

Automatic yarn drawing-in equipment

The invention relates to automatic yarn drafting equipment suitable for sample looms. The automatic yarn drafting equipment comprises a heddle feeding mechanism mounted on a rack, a heddle conveying mechanism, a yarn feeding mechanism, a yarn hooking mechanism, a reed feeding mechanism and a heddle arranging mechanism, the heddle feeding mechanism stores heddle at a heddle storage place at a time and conveys the same to a corresponding process position of the automatic yarn drafting equipment for single heddle separation, the reed feeding mechanism and the heddle arranging mechanism are at tail-end workstations of the equipment, and the heddle penetrates among workstations; the heddle conveying mechanism conveys the heddle which is separated successfully to the workstations for working, the yarn feeding mechanism conveys yarn equal in length at a yarn storage place to the top end of the equipment, the yarn hooking mechanism utilizes an arrow belt to hook vertical yarn at a yarn feeding workstation into the heddle and steel reeds and stores ends of the yarn at the tail end of the yarn hooking mechanism, the reed feeding mechanism orderly conveys the steel reeds, each steel reed gap allows 1-3 yarns to penetrate, and the heddle arranging mechanism sequentially arranges the heddle which successfully penetrate the yarns according to a set sequence.

Owner:JIANGYIN TONGYUAN TEXTILE MACHINERY

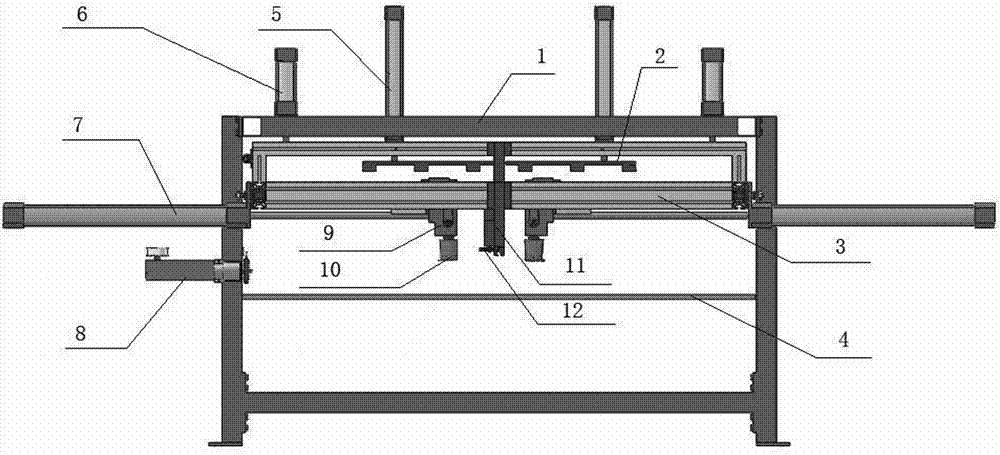

A tension type electric blanket wiring machine

The invention relates to a tension-type electric blanket wiring machine, and belongs to the field of household appliances. The machine comprises a frame, a wire pressing plate, a movable workbench and a fixed workbench, wherein the wire pressing plate is connected with the frame through oil cylinders B; the movable workbench which comprises a stop block is arranged on the upper half part of the frame; and the fixed workbench is arranged on the lower half part of the frame. The machine is convenient to operate, and wiring is uniform; and by the machine, threading quality is improved, and manpower and financial resources are saved simultaneously.

Owner:成都彩虹电器(集团)股份有限公司

Drying and automatic threading device for earthworm processing

ActiveCN112197574AAccelerateReduce labor intensityFood processingFood shapingAgricultural engineeringBiology

The invention relates to the technical field of earthworm processing, in particular to a drying and automatic threading device for earthworm processing. The drying and automatic threading device for earthworm processing comprises a supporting seat, a supporting bracket, iron wires, a first conveying wheel, a first conveying belt and the like, the supporting bracket is fixedly installed on one sideface of the bottom of the supporting seat, and the two parallel iron wires are placed on the supporting bracket in a movable mode. According to the drying and automatic threading device for earthwormprocessing, the first conveying belt and two second conveying belts are matched to work, earthworms which are subjected to pretreatment can be driven to be transmitted leftwards for threading processing operation, the earthworm threading speed is increased, and the problem that hands are prone to being scratched when threading is carried out on the earthworms manually is solved.

Owner:刘洋 +1

Full-automatic efficient stringing machine

InactiveCN112352815AAvoid stab woundsSave energyMeat packaging/handling/transportingMeat shaping/cuttingStructural engineeringMachine

The invention relates to the technical field of food processing equipment, in particular to a full-automatic efficient stringing machine, which can effectively save the physical strength and time during manual stringing, simplify the operation mode, improve the stringing speed, improve the working efficiency and effectively prevent bamboo sticks from stabbing a human body by automatically stringing meat skewers. The practicability and the safety are improved; the stringing machine comprises two sets of first supports, a plurality of sets of first conveying shafts are evenly and rotationally arranged between the two sets of first supports, four sets of first conveying wheels are evenly arranged on each set of first conveying shafts, and the first conveying wheels on the multiple sets of first conveying shafts are arranged in four rows in parallel.

Owner:诸城市东方食品有限公司

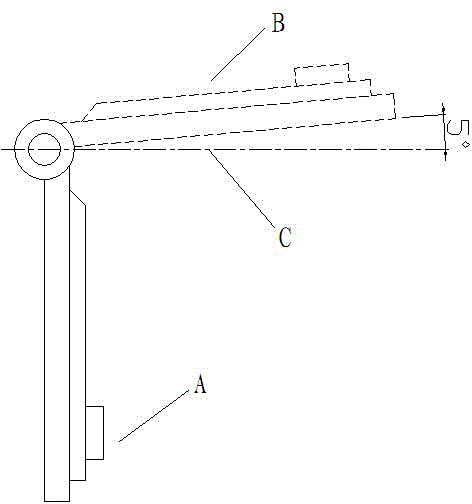

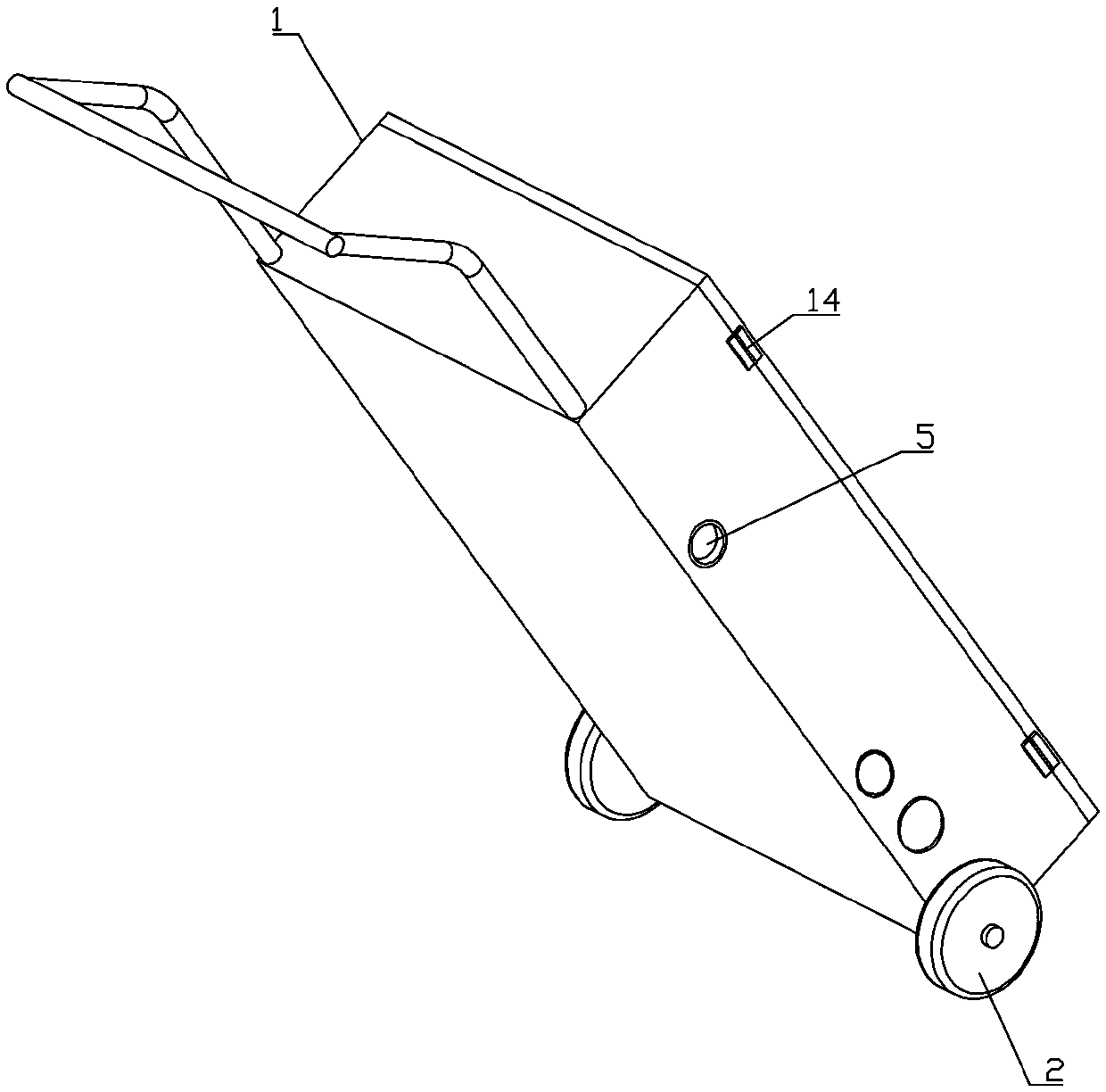

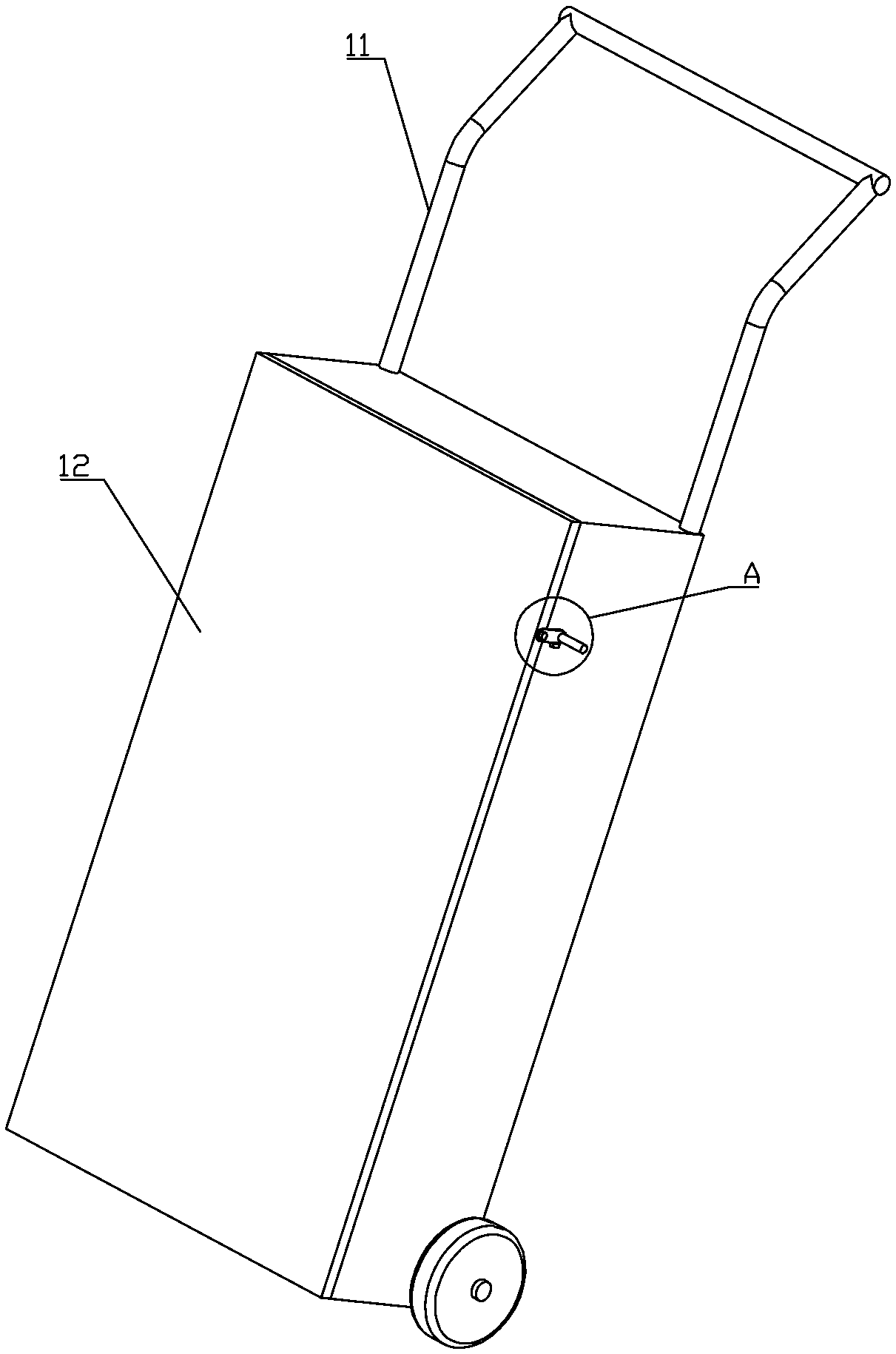

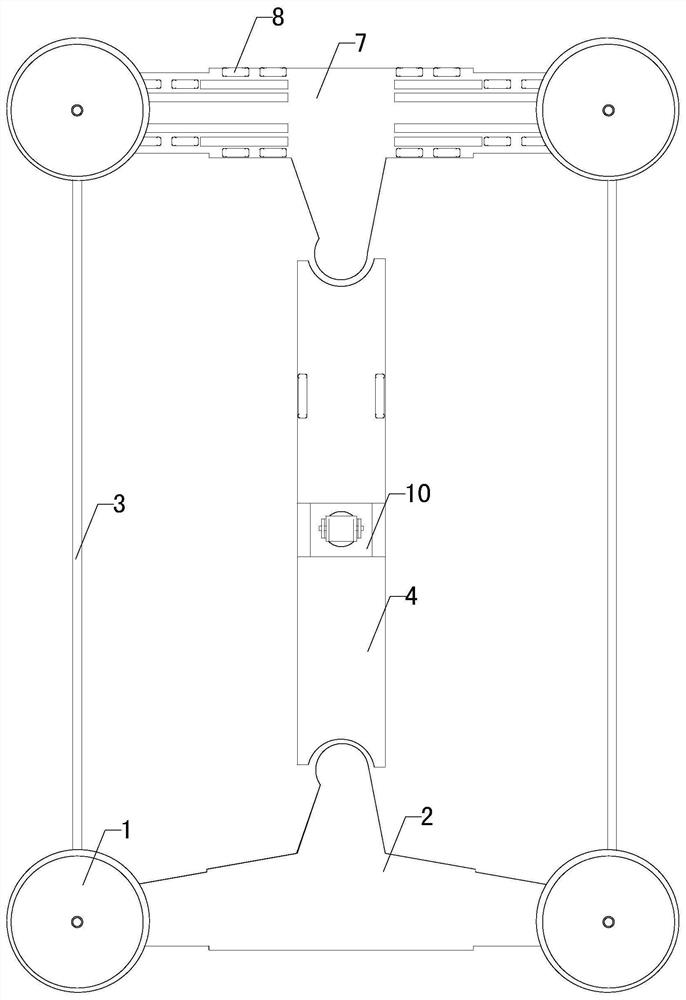

Convenient arc-shaped bridge frame threading tool

PendingCN113922283APrecise positioningImprove threading efficiencyApparatus for laying cablesDrive wheelStructural engineering

The invention relates to the technical field of mechanical and electrical installation, in particular to a portable arc-shaped bridge threading tool, equipment is placed between arc-shaped bridges by adjusting a telescopic front vehicle arm and a telescopic rear vehicle arm, the migration number is determined according to site conditions, and finally, the equipment is controlled by a controller to move forwards to complete migration of cables. The threading efficiency is effectively improved, the threading speed is increased, the construction period pressure in the later installation construction process can be relieved, a large number of materials and manpower are not needed, machining is convenient, operation is easy, the threading speed can be effectively increased, the time cost is saved, and practicability is high; the tool comprises a turning limiting stopper, a telescopic front vehicle arm, a limiting spring, a middle vehicle arm, a camera, an auxiliary driving wheel, a telescopic rear vehicle arm, a rope clamp, a driving wheel and a telescopic lamp, the telescopic front vehicle arm is hinged to the front portion of the middle vehicle arm, and the telescopic rear vehicle arm is hinged to the rear portion of the middle vehicle arm.

Owner:CHINA CONSTR THIRD ENG BUREAU GRP CO LTD

Intelligent 5G network cable threading mechanism

The invention relates to an intelligent 5G network cable threading mechanism. The intelligent 5G network cable threading mechanism comprises a threading part and a wire feeding part, wherein a user grasps a machine through an auxiliary side handle and a rear handle, the threading part and the wire feeding part are connected through a brake wire, the brake wire is divided into an inner layer and anouter layer, one fixed end of an outer wire is fixedly arranged on an outer wire linking groove, and an inner wire penetrates through a steel wire threading hole to wind on a shaft with a hole. The mechanism is advantaged in that operation is simple, control is convenient, a switch is pressed down for use according to the situation when the device is used, the device is convenient to carry, a motor is used for controlling transmission through a gear set, the effects of large power and low power consumption are realized, cost is reduced, and the material is greatly saved.

Owner:王颐疆

A kind of automatic sewing needle threading method for industrial use

ActiveCN107829231BImprove needle extraction efficiencyPush needle process is stableNeedle-threading devicesMechanical engineeringSewing needle

The invention discloses an automatic sewing needle threading method for an industrial use, and belongs to the technical field of sewing threading. The specific process of the automatic sewing needle threading method comprises the steps that a required needle is rotated to the corresponding position of a needle pushing rod one, the needle push rod one penetrates through a rod penetrating hole and enters into a needle pushing slot, and the needle is pushed into a needle delivery slot; the needle is moved in the needle delivery slot towards the direction close to a thread drawing device under theaction of a needle pushing slider of a needle pushing rod two, a thread is placed in a thread placement slot by the thread drawing device through a thread drawing component on a caterpillar, and a needle hole is covered with the thread; a needle threading rod of a threading device is driven to move downward by a connecting rod of a needle threader, the needle body is pressed by a needle pressingblock, the needle threading rod continues to press downward to finish a threading process, the thread is cut by a thread cutting device, and an electromagnet of a needle ejector is energized to absorbthe needle; according to the automatic sewing needle threading method for the industrial use, the automation from needle storage and needle ejecting is achieved, no manpower is needed to pick and place the needle and adjust the direction of the needle hole manually, and the amount of the needle can be displayed by a needle storage device so that needles can be timely added to the needle storage device by people, and the needle threading efficiency is improved.

Owner:临沂经开土地储备开发集团有限公司

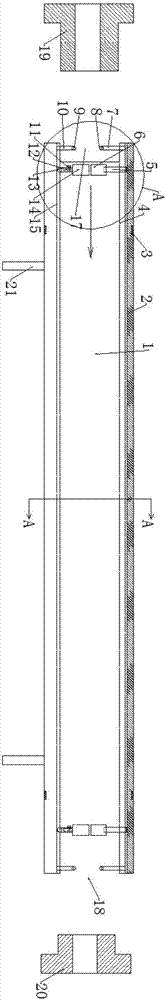

A wire feeding device for a multifunctional terminal machine

InactiveCN105470777BRealize transmissionEasy to operateLine/current collector detailsDrive wheelEngineering

The invention relates to a wire feeding device for a multi-functional terminal machine. The wire feeding device comprises a support frame (1), a wire feeding plate (2) and a correcting plate (18), wherein the wire feeding plate (2) is arranged on the support frame (1); a wire feeding wheel device is arranged between the wire feeding plate (2) and the correcting plate (18); the wire feeding plate (2) is provided with a pair of wire feeding wheels (3) and a motor (5); the motor (5) drives the pair of wire feeding wheels (3) to synchronously rotate oppositely; the motor (5) is arranged on the support frame (1); the wire feeding wheel device comprises a guide plate (4), a driven wheel (16) and an adjusting device; the adjusting device is used for adjusting the driven wheel (16); the guide plate (4) is provided with a guide pipe (9); and the guide pipe (9) corresponds to the center of the upper end of the driven wheel (16). Through coordination of the wire feeding wheel device and the wire feeding wheels, when an electric wire penetrates between the pair of wire feeding wheels, the driven wheel 16 and the wire feeding wheels can be always propped against the electric wire when working by adjusting the driven wheel 16, so that transmission of the electric wire can be relatively stably achieved.

Owner:平湖市诚成电子科技有限公司

Efficient automatic threading system

ActiveCN107841836AImprove needle extraction efficiencyPush needle process is stableNeedle-threading devicesBiomedical engineeringControl system

The invention discloses an efficient automatic threading system, and belongs to the technical field of sewing threading. The system includes a needle storage device, a needle pushing device, a needlemanipulation device, a thread pulling device, a needle threading device and a control system; one side of the needle storage device is provided with the needle pushing device, and the other side is provided with the needle manipulation device; the end, away from the needle storage device, of the needle manipulation device is provided with the thread pulling device, and the needle threading deviceis arranged above the end, close to the thread pulling device, of the needle manipulation device; the control system controls all the devices of the automatic threading system to action. According tothe system, through coordination and cooperation of the control system and all the devices, automation of needle taking, thread pulling and needle threading is improved; a counting device is arranged,so that it is convenient for staff to know the number of remaining needles in a needle box and supplement needles in time; the speed of threading is increased, and the working efficiency is improved.

Owner:临沂经济开发区城市建设投资有限公司

Constant-tension warp and k'o-ssy feeding machine

The invention discloses a constant-tension warp and k'o-ssy feeding machine. The constant-tension warp and k'o-ssy feeding machine comprises a k'o-ssy machine rack, wherein a front chest beam is arranged at one end of the k'o-ssy machine rack; the front chest beam is connected with the k'o-ssy machine rack; a cloth rolling roller is arranged below the front chest beam; the cloth rolling roller isrotatably mounted on the k'o-ssy machine rack; the cloth rolling roller is in transmission connection with a power output shaft of the cloth rolling drive motor; the other end of the k'o-ssy machine rack is equipped with a swing shaft for tightening warp silks; the left end of the swing shaft is rotatably mounted at the outer end of a left swing rod; the right end of the swing shaft is rotatably mounted at the outer end of a right swing rod; the inner end of the right swing rod and the inner end of the left swing rod are mounted on the k'o-ssy machine rack through the swing rod shaft; the axisof the swing rod shaft is parallel to the axis of the swing shaft; a warp silk feeding roller is arranged near the swing shaft; and the warp silk feeding roller is rotatably mounted on the k'o-ssy machine rack. The invention aims to provide the constant-tension warp and k'o-ssy feeding machine which can increase warp penetrating speed, guarantees straightness and uniformity of warp yarns, so thatproduct quality can be guaranteed, and working efficiency of k'o-ssy knitting is improved.

Owner:沈红

Automatic sewing needle threading method for industrial use

ActiveCN107829231AImprove needle extraction efficiencyPush needle process is stableNeedle-threading devicesControl systemSewing needle

The invention discloses an automatic sewing needle threading method for an industrial use, and belongs to the technical field of sewing threading. The specific process of the automatic sewing needle threading method comprises the steps that a required needle is rotated to the corresponding position of a needle pushing rod one, the needle push rod one penetrates through a rod penetrating hole and enters into a needle pushing slot, and the needle is pushed into a needle delivery slot; the needle is moved in the needle delivery slot towards the direction close to a thread drawing device under theaction of a needle pushing slider of a needle pushing rod two, a thread is placed in a thread placement slot by the thread drawing device through a thread drawing component on a caterpillar, and a needle hole is covered with the thread; a needle threading rod of a threading device is driven to move downward by a connecting rod of a needle threader, the needle body is pressed by a needle pressingblock, the needle threading rod continues to press downward to finish a threading process, the thread is cut by a thread cutting device, and an electromagnet of a needle ejector is energized to absorbthe needle; according to the automatic sewing needle threading method for the industrial use, the automation from needle storage and needle ejecting is achieved, no manpower is needed to pick and place the needle and adjust the direction of the needle hole manually, and the amount of the needle can be displayed by a needle storage device so that needles can be timely added to the needle storage device by people, and the needle threading efficiency is improved.

Owner:临沂经开土地储备开发集团有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com