A tension type electric blanket wiring machine

A technology of electric blankets and wiring machines, which is applied in the direction of electric heating devices, ohmic resistance heating, electrical components, etc., can solve the problems of slow threading speed, uneven wiring, manpower consumption, etc., and achieve convenient operation, fast threading speed, and uniform wiring Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

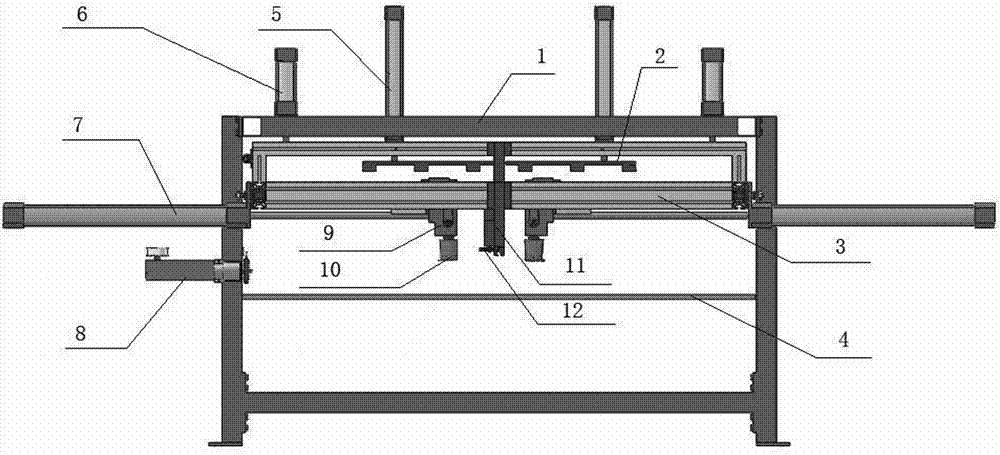

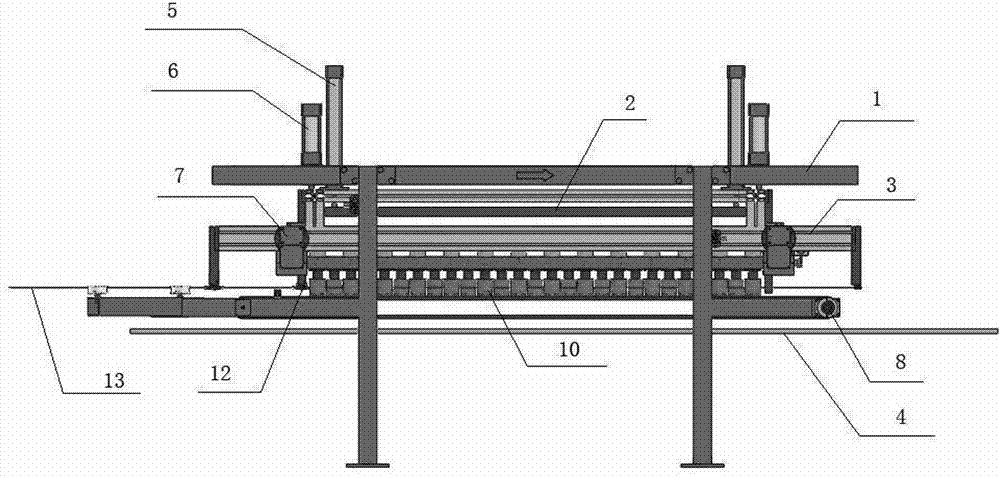

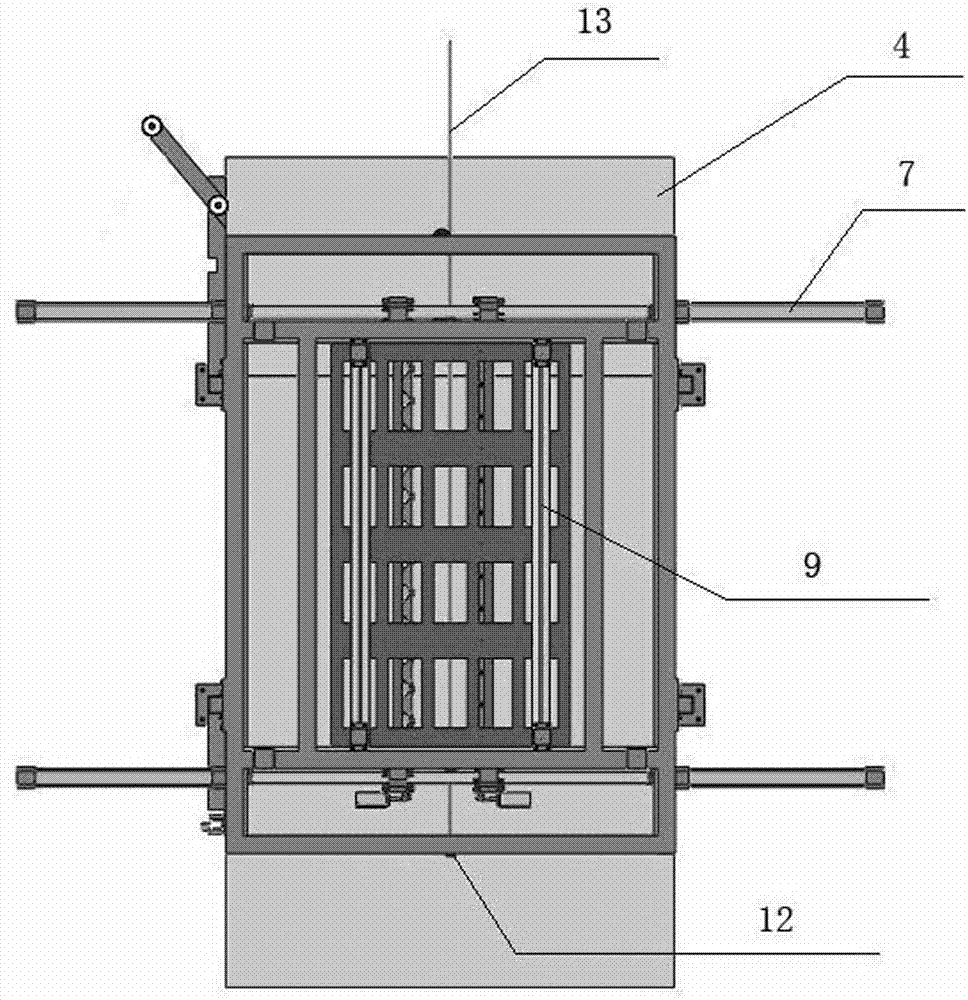

[0014] see Figure 1-4 , the present invention includes frame, crimping plate, movable workbench and fixed workbench. The frame is composed of an iron frame (1), a wire feeding mechanism (8), a wire pulley (12), two oil cylinders A (6), and two cylinders (5), wherein the wire feeding mechanism (8) and the wire pulling Wheel (12) is installed on the front and the rear of iron frame (1) respectively, and two oil cylinders A (6), two cylinders (5) are installed on the top of iron frame (1) respectively. The movable workbench is composed of two pull wire mechanisms (9), four oil cylinders B (7), and stoppers (11). Wherein the stopper (11) is fixed on the very center of the movable workbench, and the bottom of the two wire pulling mechanisms (9) has several grabbing posts (10) and are installed parallel to each other on the left and right sides of the movable workbench, each Two oil cylinders B (7) are connected on the side of the cable mechanism (9).

[0015] First use the oil ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com