Degradable Zn-Ti binary biomedical material and preparation method thereof

A technology of biomedical materials and biomaterials, applied in the field of degradable Zn-Ti binary biomedical materials and their preparation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

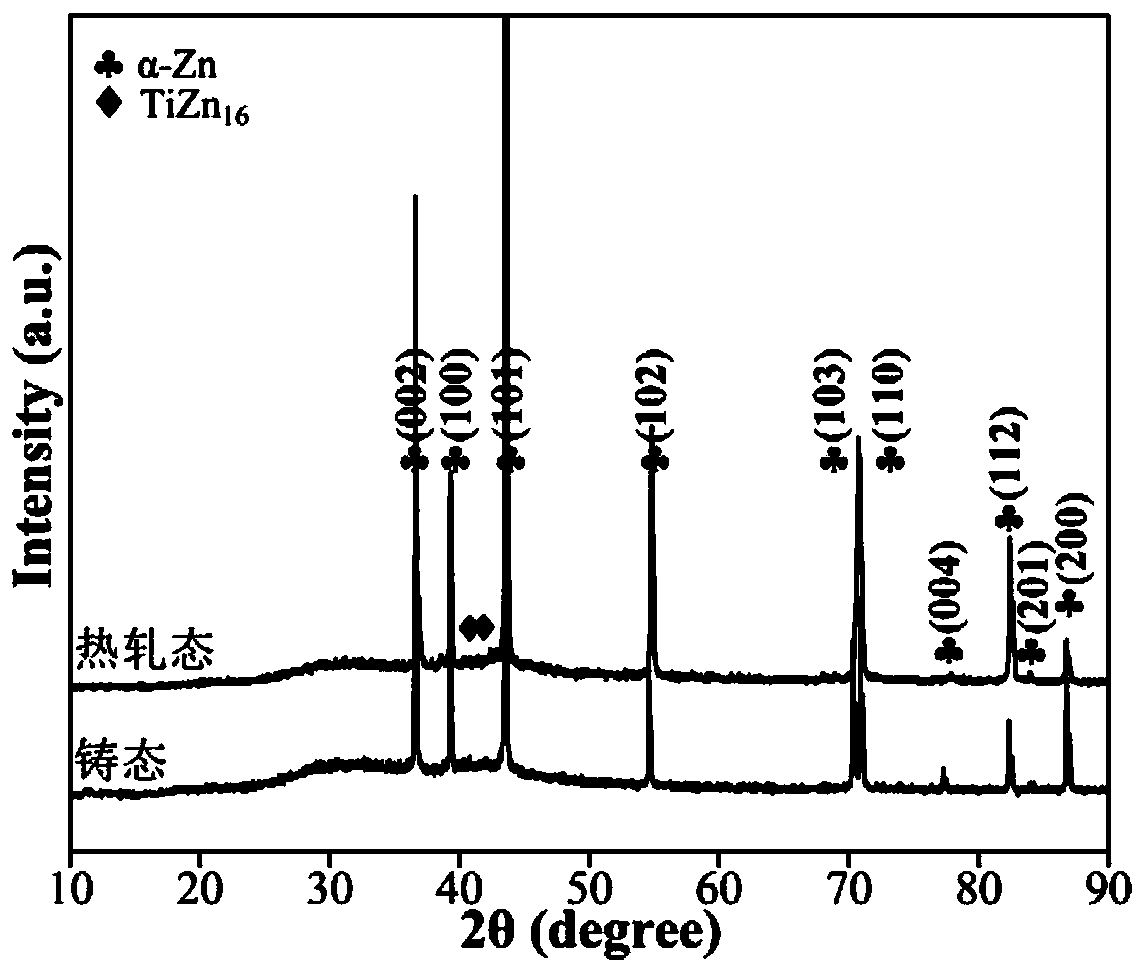

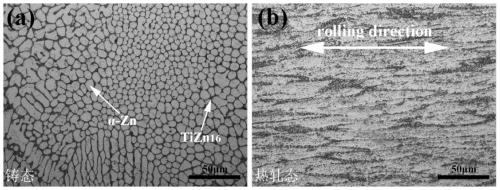

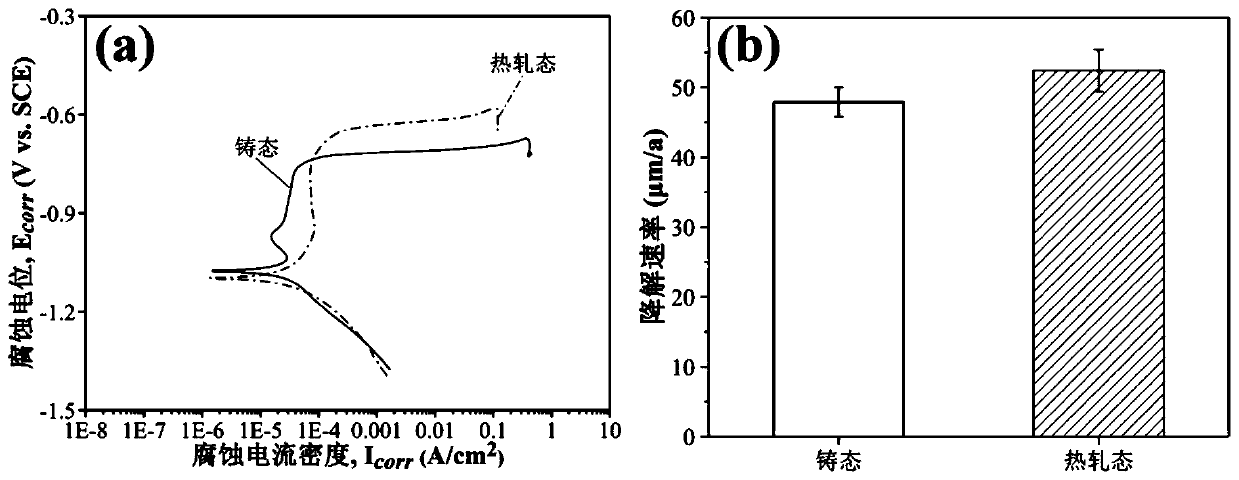

[0038] like Figure 1 to Figure 4 As shown, the present invention discloses a degradable Zn-Ti binary biomedical material and its preparation method. Firstly, pure Zn ingot (99.999wt.%) and Zn-3Ti master alloy (containing 3.17wt.% Ti) are used as raw materials , and weighed according to the mass ratio in the binary Zn-0.2Ti alloy composition. Then put pure zinc into a graphite crucible and place it in a pit furnace for melting. 2 Under the protection of the atmosphere, heat to 560°C for smelting. After the pure zinc is completely melted, add the Zn-3Ti master alloy, and press the Zn-3Ti master alloy into the liquid surface to avoid the phenomenon that the master alloy cannot be melted due to floating. Adjust the temperature to 580°C. After the master alloy is fully melted, continue to stir with a graphite rod for 2 minutes. After standing for 5 minutes, carry out slag removal treatment, and lower the pouring temperature to 540°C. Finally, it is poured into a steel mold prehe...

Embodiment 2

[0051] Firstly, pure Zn ingot (99.999wt.%) and Zn-3Ti master alloy (containing 3.17wt.% Ti) were used as raw materials, and weighed according to the mass ratio of the binary Zn-0.05Ti alloy composition. Then put pure zinc into a graphite crucible and place it in a pit furnace for melting. 2 Heating to 560°C under atmosphere protection for smelting, after the pure zinc is completely melted, add Zn-3Ti master alloy, and press the Zn-3Ti master alloy into the liquid surface to avoid the phenomenon that the master alloy cannot be melted due to floating up; adjust the temperature to 580°C, after the master alloy is fully melted, continue to stir with a graphite rod for 2 minutes, after standing for 5 minutes, carry out slag removal treatment, and lower the pouring temperature to 540°C. Finally, it is poured into a steel mold preheated to 250°C, and the metal ingot is obtained after solidification. The metal ingot is kept at 340°C for 10 hours for homogenization treatment to improve...

Embodiment 3

[0054] First, pure Zn ingot (99.999wt.%) and Zn-3Ti master alloy (containing 3.17wt.% Ti) were used as raw materials, and weighed according to the mass ratio of the binary Zn-1Ti alloy composition, and then pure zinc was put into Graphite crucible and placed in a pit furnace for melting, in Ar 2 Under the protection of the atmosphere, heat to 580°C for smelting. After the pure zinc is completely melted, add the Zn-3Ti master alloy, and press the Zn-3Ti master alloy into the liquid surface to avoid the phenomenon that the master alloy cannot be melted due to floating. Adjust the temperature to 560°C. After the master alloy is fully melted, continue to stir with a graphite rod for 3 minutes. After standing for 5 minutes, carry out slag removal treatment, and lower the pouring temperature to 530°C. Finally, pour into a preheated to 250°C In the steel mold, metal ingots were obtained after solidification; the metal ingots were homogenized at 340°C for 10 hours to improve the segre...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Yield strength | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

| Vickers hardness value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com