Technique of thrilling through fire lighter for firecracker

A fireworks and technology technology, applied in fireworks, offensive equipment, weapon types, etc., can solve the problems of poor safety factor, leakage of fireworks powder, troublesome operation, etc., and achieve the effect of low quality requirements, fast penetration speed, and simple operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] Below in conjunction with accompanying drawing and specific embodiment the present invention will be further described:

[0016] The step characteristics of its technical solution are:

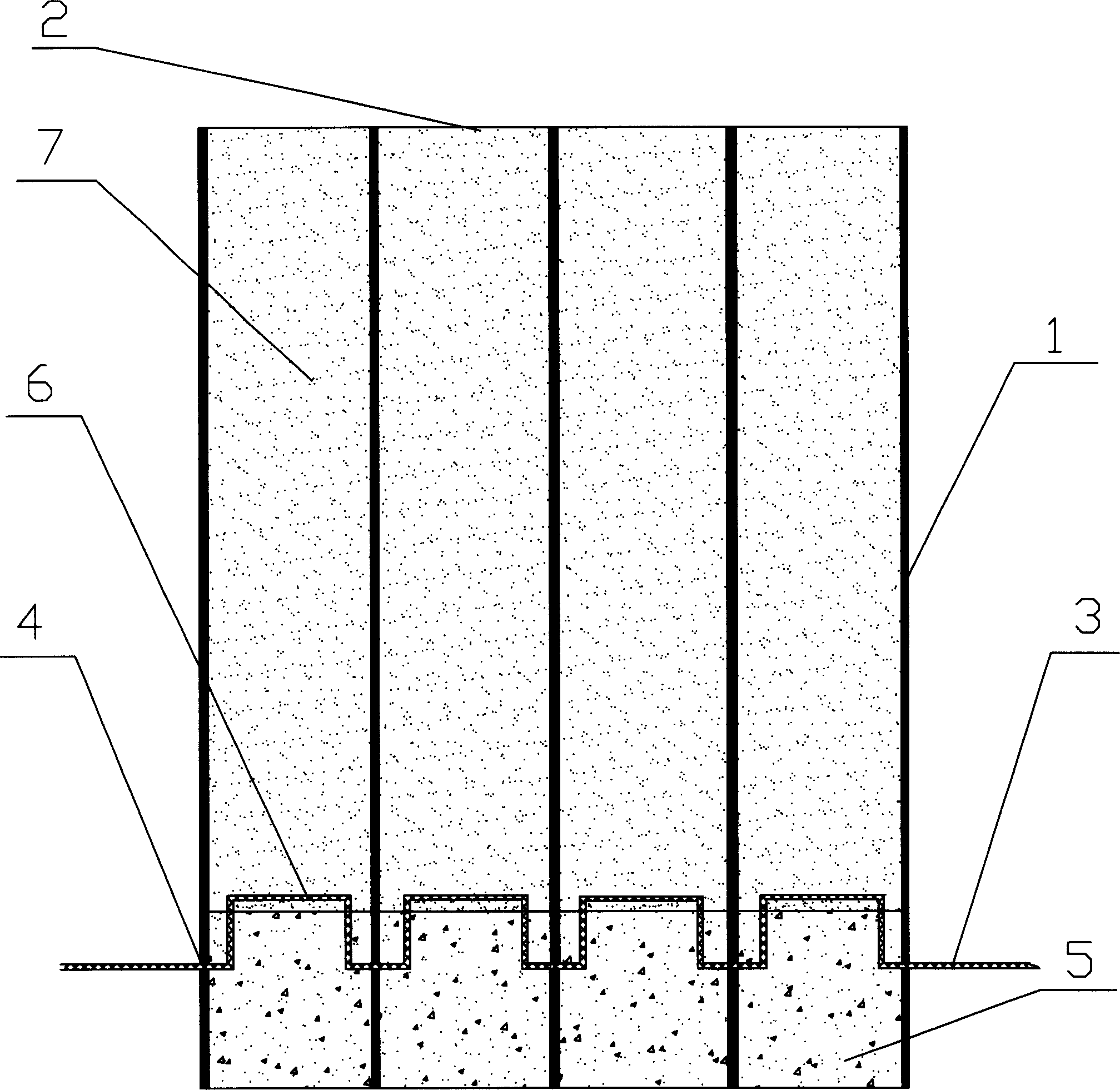

[0017] 1. Place 16 fireworks tubes 1 in a square solid-bottomed basket whose basket height is one-third of the height of the fireworks tube 1, insert a paper sheet coated with glue on both sides on the interface between two rows of fireworks tubes 1, and use A bundle of ropes or metal wires, which is glued and shaped into a square firecracker assembly 2;

[0018] 2. Use an electric long steel drill to pierce from the appropriate position at the lower part of any end of the firecracker barrel assembly 2 to the symmetrical end, and then use a needle to pass the firecracker lead wire 3 through the needle hole 4;

[0019] 3. Lift up the lead wires 3 in the barrel from the lower part of each individual firecracker 1 in turn, so that the lead wires 3 of the firecrackers in the barrel 1 are c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com