tool changing system

A tool replacement and tool technology, applied in the direction of manufacturing tools, manipulators, chucks, etc., can solve the problems such as the relative position of the locking bolts, operation failures, etc., to achieve high operational safety and availability, simple structure, and control costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

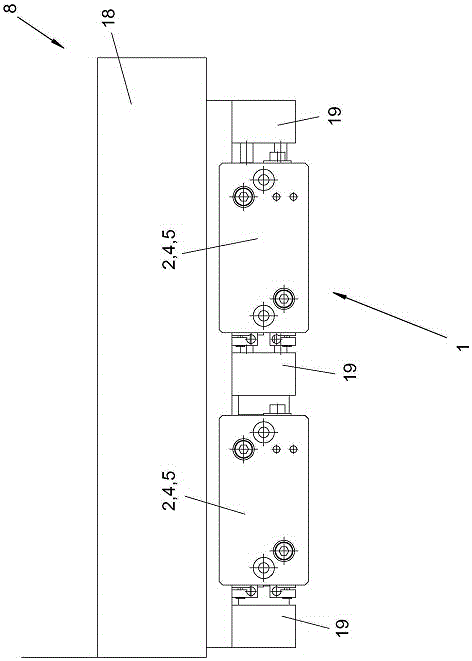

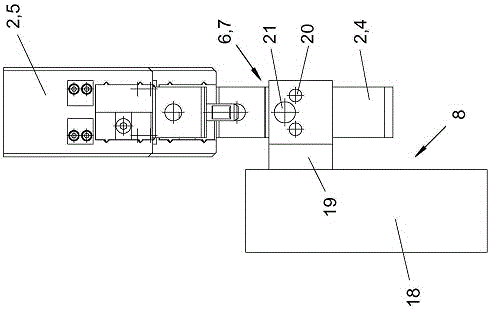

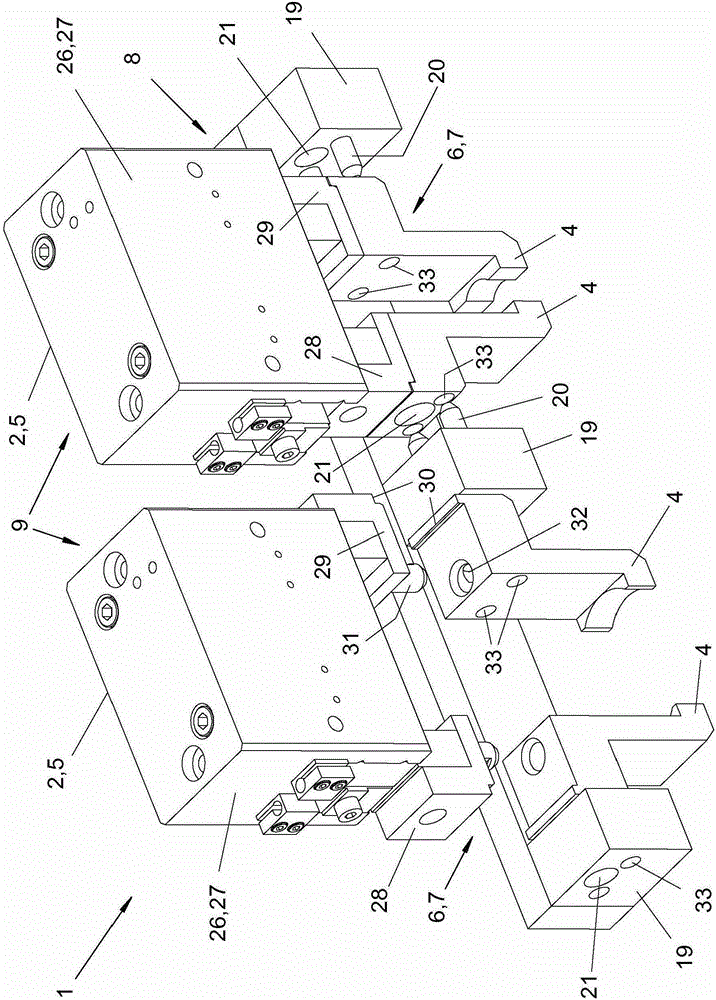

[0063] The invention relates to a tool changing system 1 and a method for changing tool parts 4 . The invention also relates to a machining device 3 equipped with a tool changing system 1 .

[0064] Figure 1 to Figure 4 A tool changing system 1 is shown with, for example, two multi-part tools 2 , which are designed, for example, as tongs, in particular parallel tongs. Each tool 2 consists of a tool part 5 , to which one or more exchangeable tool parts 4 are coupled by means of a coupling device 6 and an associated form-fitting locking device 7 .

[0065] Two tools 2 of the same type are shown in the figure to illustrate different operating positions. Alternatively, the number of tools 2 in the tool changing system 1 can be more or less than two. The tools 2 can be of the same type and have, for example, identical or similar tool parts 5 , which can be coupled with possibly all exchangeable tool parts 4 . Alternatively, the multi-part tools 2 can also be completely differe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com