Variable-stiffness semi-active horizontal stabilizer bar of passenger car

A technology of lateral stabilizer bar and stabilizer bar, which is applied in the directions of vehicle components, interconnection systems, transportation and packaging, etc., can solve the problems of inability to prevent roll, noise, and inability to meet variable stiffness, so as to achieve soft movement and reduced noise problems. , the effect of saving power

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

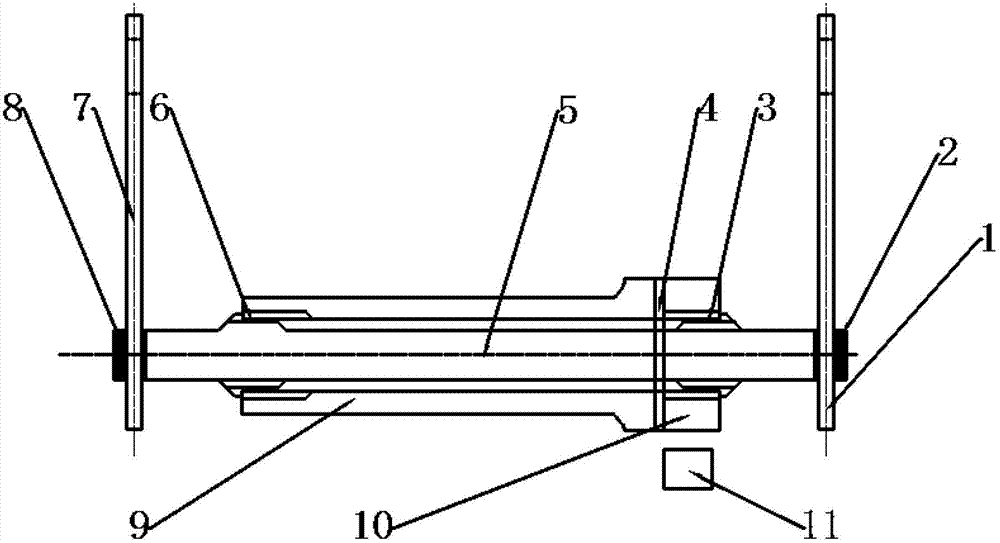

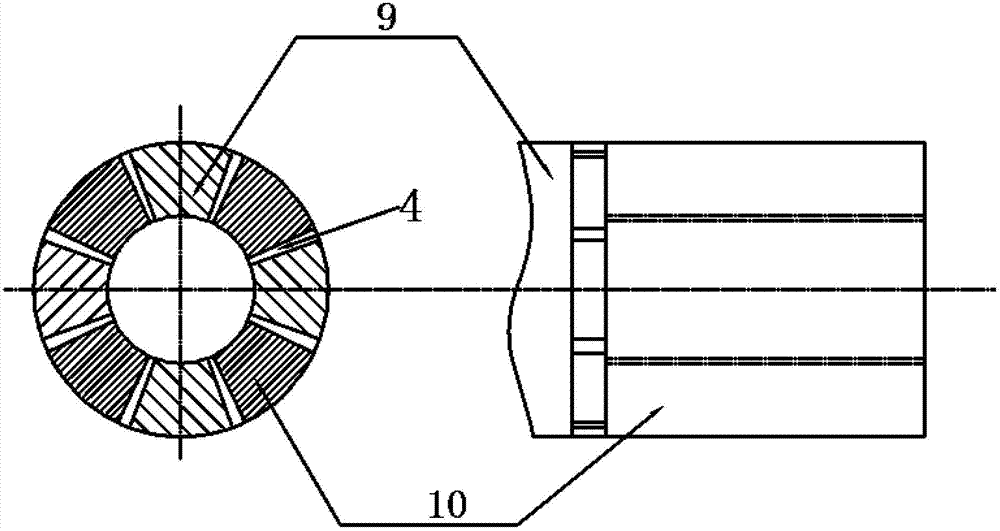

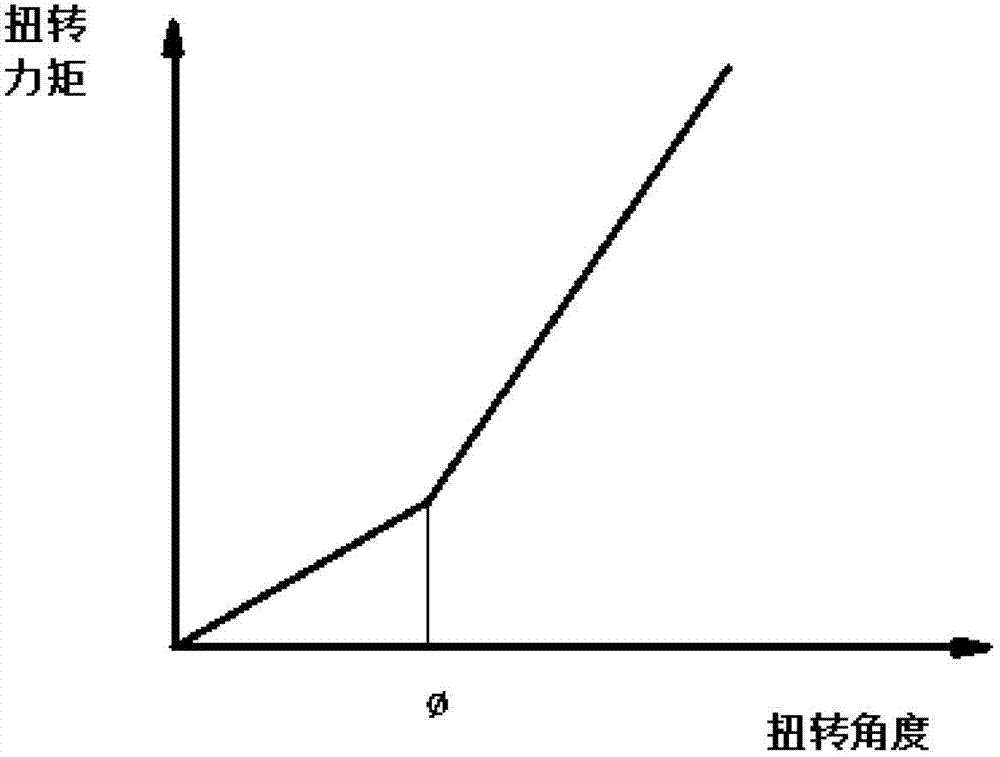

[0016] figure 1 Shown is the passenger car variable stiffness semi-active stabilizer bar of the present invention, which includes a middle stabilizer bar 5, a right stabilizer bar 1, a left stabilizer bar 7, a long sleeve 9 and a short sleeve 10, and one end of the middle stabilizer bar 5 is connected to the right stabilizer bar. One end of the stabilizer bar 1 is fixedly connected, the other end of the middle stabilizer bar 5 is fixedly connected with one end of the left stabilizer bar 7, and the other end of the right stabilizer bar 1 is movably connected with the lower swing arm of the automobile by means of an end bracket. The other end of the stabilizer bar 7 is movably connected with the lower swing arm of the car by means of an end bracket, and the long sleeve 9 and the short sleeve 10 are axially engaged together through the engaging teeth at the engaging end, and are sleeved on the periphery of the middle stabilizer bar 5 , There is a gap 4 between the teeth of the lo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com