Method for installing a functional component on a vehicle shell and centering element for carrying out the method

An installation method and a technology of functional components, which are applied in the field of installing functional components on vehicle shell plates and centering parts for implementing the same, can solve the problems of complex assembly and high cost of headlight cleaning devices, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

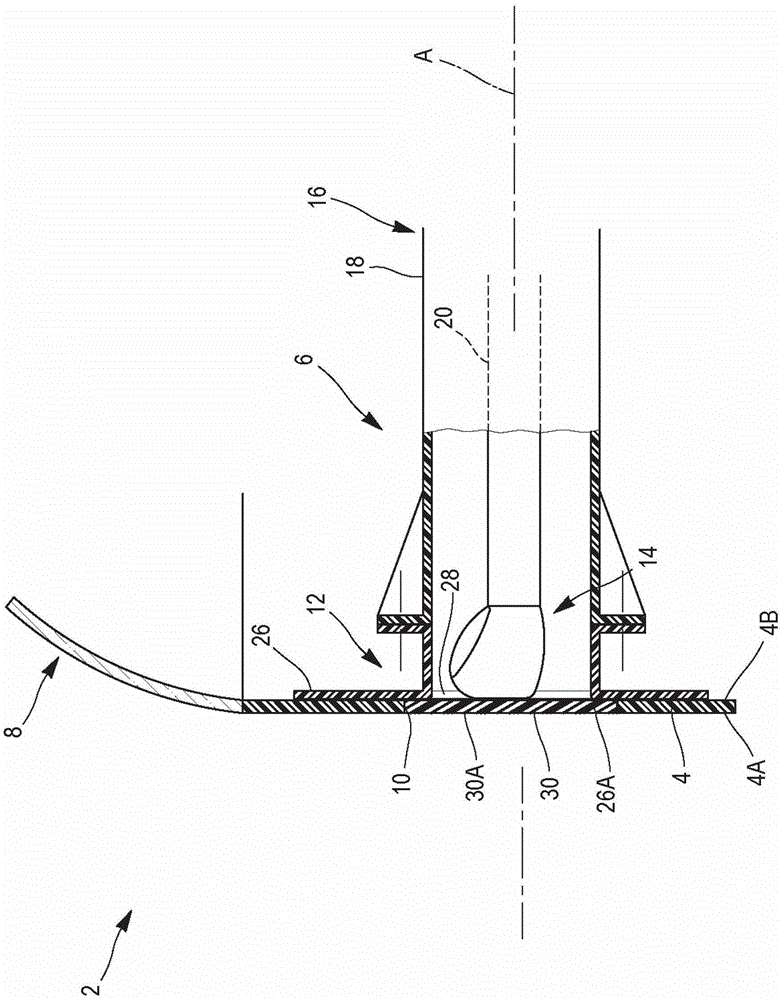

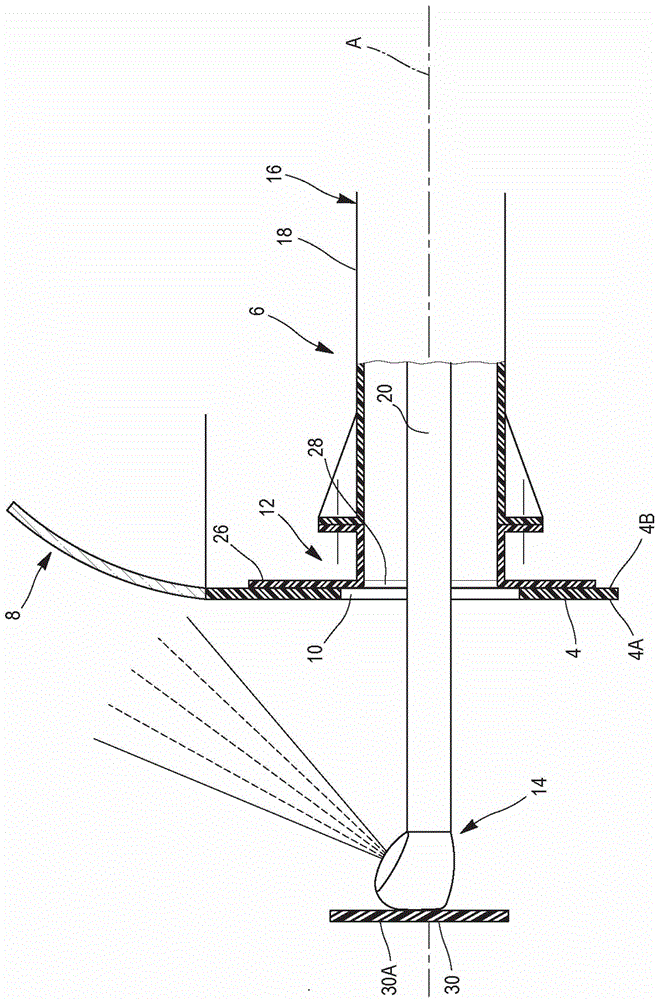

[0029] Such as figure 1 and figure 2 As shown, the assembly 2 includes a body panel 4 and a headlight cleaning device 6 , and the headlight cleaning device 6 is installed on the body panel 4 for cleaning the lighting headlight 8 .

[0030] The body panel 4 has opposing outer and inner surfaces 4A, 4B. The outer surface 4A is intended to be visible towards the outside of the motor vehicle. The body panel 4 is provided with a through opening 10 extending between the outer surface 4A and the inner surface 4B.

[0031] The body panel 4 is the outer shell panel of the motor vehicle, which defines the outer shape of the motor vehicle. The body panel 4 is, for example, a skin covering the front bumper of a front bumper assembly of a motor vehicle for at least partially absorbing the energy of a head-on impact.

[0032] The headlights 8 are, for example, headlights for illuminating the road ahead of the motor vehicle. The headlights 8 comprise, in a manner known in the art, one ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com