Method and device for filling containers

A filling and container technology, which is applied in the field of filling containers with the help of filling mechanisms, can solve the problems of uncontrollable, polluted bottles, and unreliable removal, etc., and achieve the effect of reducing filling errors and inhibiting the aggravation of wear

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] Preferred embodiments will be described below with reference to the accompanying drawings. Identical, similar or identically acting parts are identified here with the same reference numerals and their repetition is sometimes omitted below in order to avoid a lengthy description.

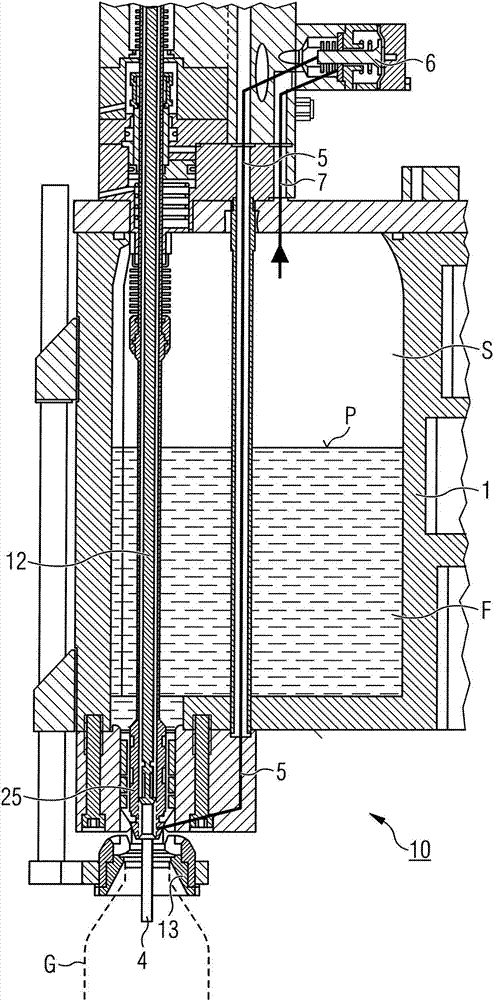

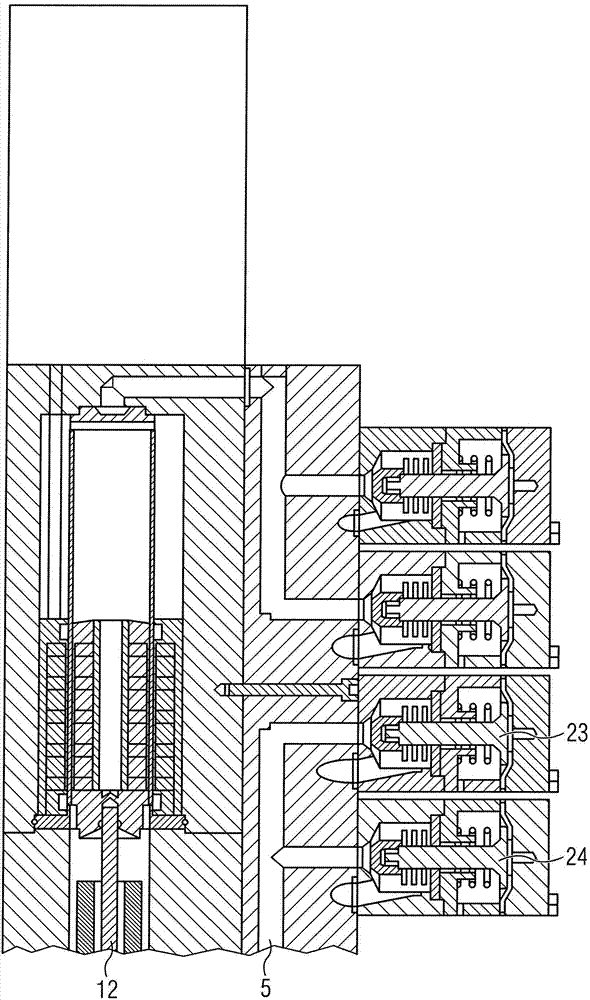

[0033] like figure 1 and figure 2 The device shown is designed, for example, to fill a container G with a liquid F, such as beer or champagne, for example. The liquid F is contained up to the level P in a storage container, which can be formed, for example, in the form of a ring container 1 in a ring filling machine. figure 1 A sectional view of a filling device 10 is shown here, which is connected to an annular container 1 and is designed to fill a container G. FIG.

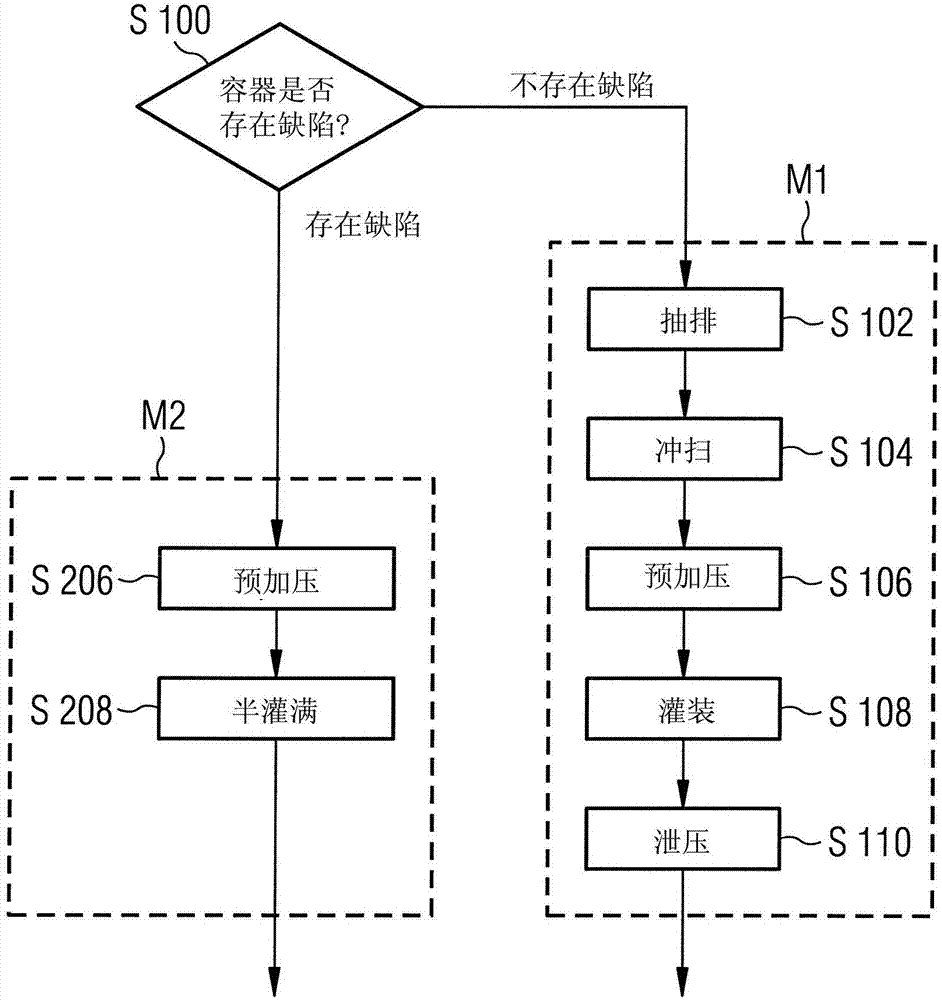

[0034] To fill container G with an oxygen-sensitive liquid such as beer or champagne, container G is evacuated to reduce or remove oxygen from the atmosphere and flushed with a purge gas (in this case CO 2 ) to clean. The ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com