Roving frame

A technology of roving frame and roving, which is applied in textiles and paper making, etc., can solve the problem of inability to clean the roving frame reliably, and achieve the effect of reducing power, reliable cleaning and saving energy.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

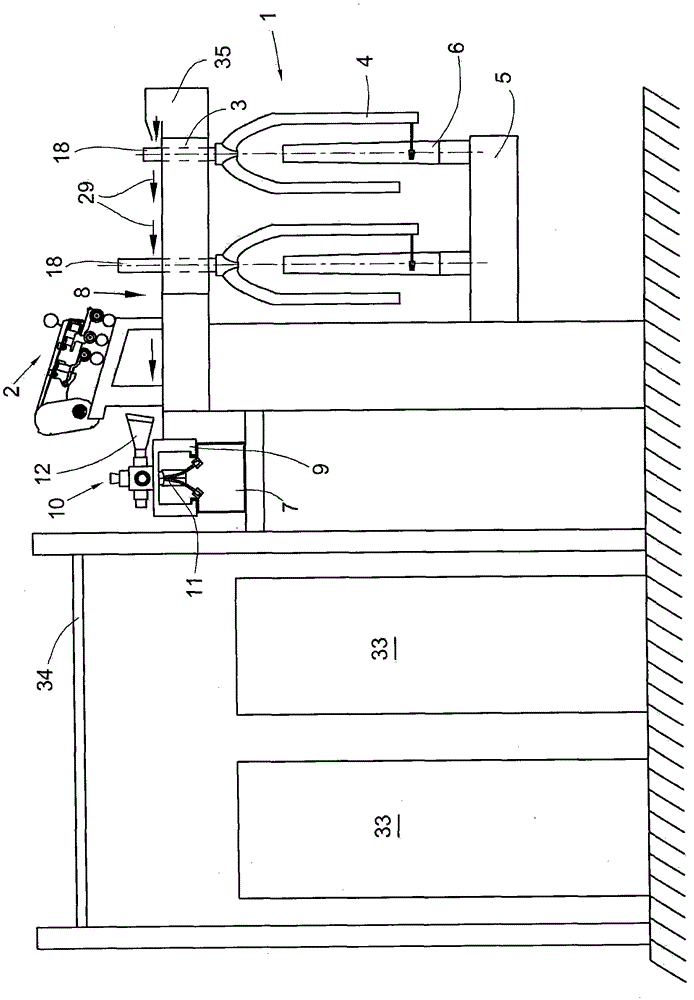

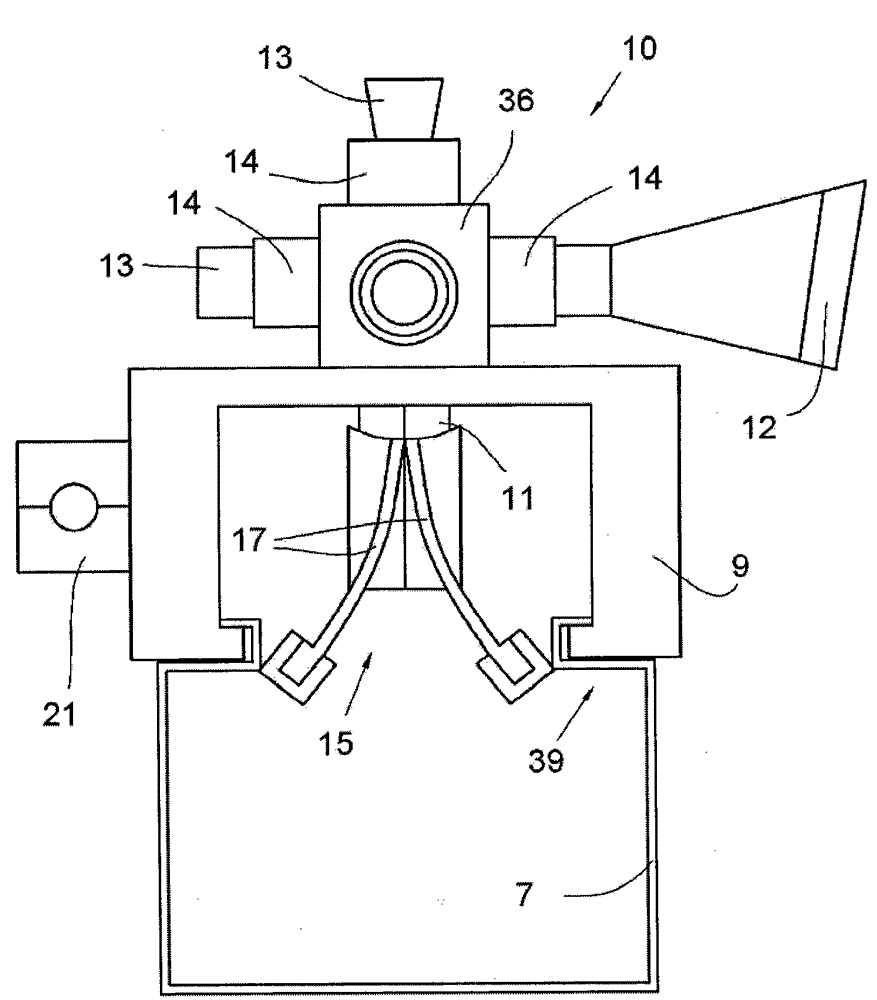

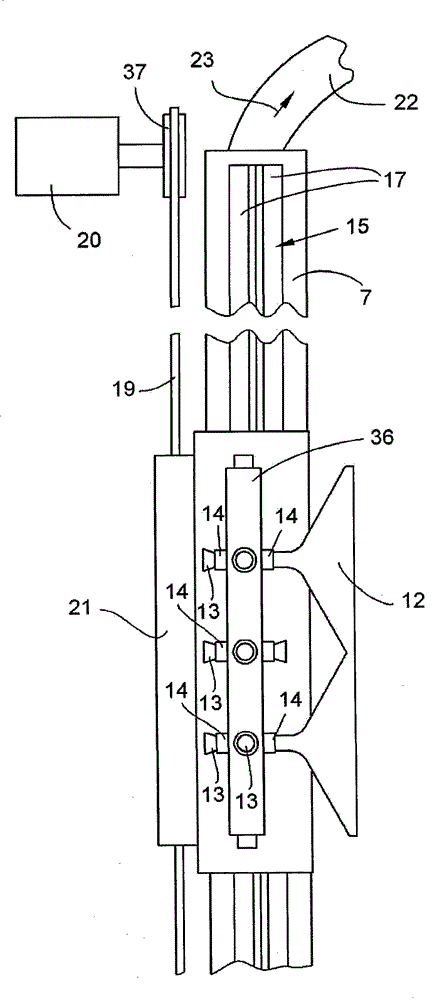

[0026] figure 1 A roving frame 1 according to the invention, also called a flyer roving frame, is shown with a drafting device 2 , a top beam 3 , a flyer 4 as well as a spindle rail 5 and a spindle bar 6 . figure 1 A side view of the roving frame is shown, which in turn shows its transverse view. Below the drafting device 2 there is a substantially flat outer surface 8 . This surface 8 extends from the region of the drafting device 2 to the flyer sleeve 18 .

[0027] The rovings are stored in cans 33 . The roving is fed to the drafting device 2 via guide rollers (not shown) fixed on the support tube 34 . The roving passes through the drafting device 2 and through the flyer sleeve 18 to the flyer 4 and finally is wound on a roving or flyer bobbin (not shown) arranged on the spindle bar 6 . Along the longitudinal direction of the roving frame 1 a large number of other stations are provided.

[0028] Near the surface 8 to be cleaned below the drafting device 2, an air blowin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com