Side compression device for laying ballastless track sleeper

A ballastless track and sleeper technology, which is used in tracks, track laying, track maintenance, etc., can solve the problems of excessive concrete discharge, deviation of the rail row, and the floating of the rail row affecting the height of the rail surface, so as to improve the laying accuracy. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

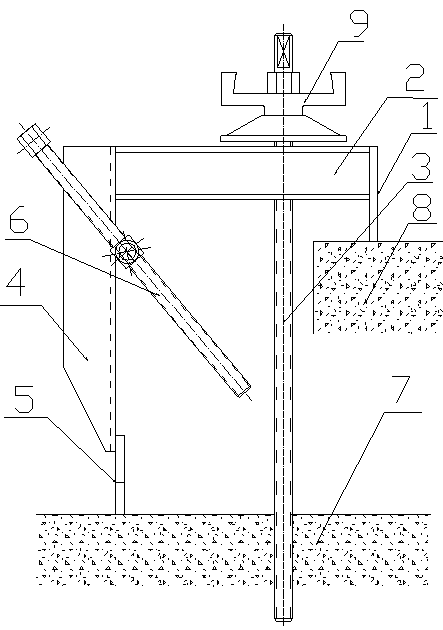

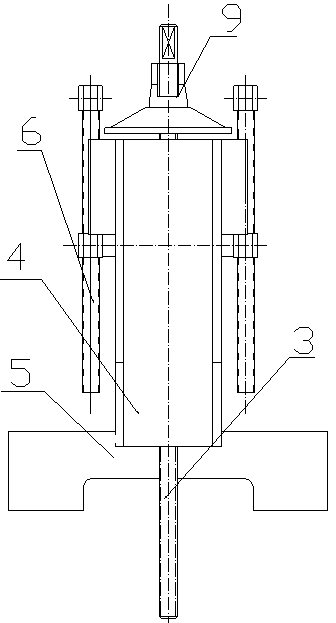

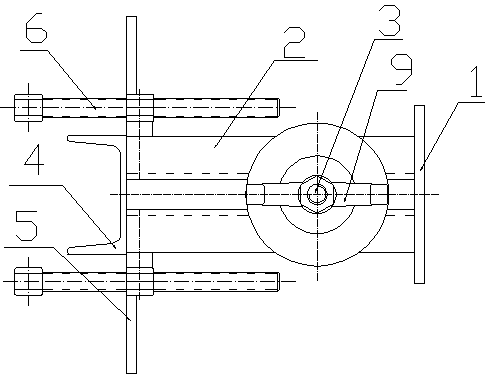

[0018] like Figure 1 to Figure 3 The shown lateral pressure device for laying ballastless track sleepers has a door-shaped bracket, and the door-shaped bracket includes a first side column 1, a top beam 2, and a second side column 4 that are sequentially fixedly connected. The length of the side column 1 is shorter than the length of the second side column 4, and the second side column 4 has a boss 5 protruding to both sides away from the end of the top beam 2, so that the width of the second side column 4 away from the end of the top beam 2 Greater than the width of other parts of the second side column 4 . The top beam 2 has an axial waist-shaped hole; the screw rod 3 of the first bolt assembly passes through the waist-shaped hole, and the head of the screw rod 3 is a square head, which can apply a large external force. When in use, the first bolt The outer surface of the part where the screw 3 of the component is implanted into the concrete is coated with planting glue. D...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com