Metal wire laying device

A technology of laying device and metal wire, which is applied to electrical components, antennas and other directions, can solve the problems of inability to lay metal wires, low laying efficiency and laying accuracy, and achieves the effect of high laying accuracy and fast speed.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

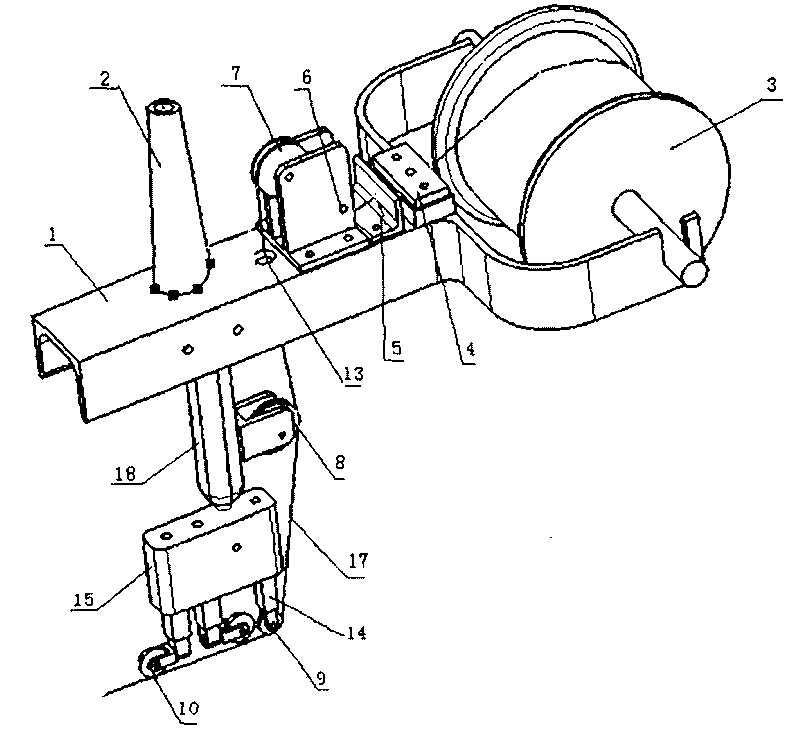

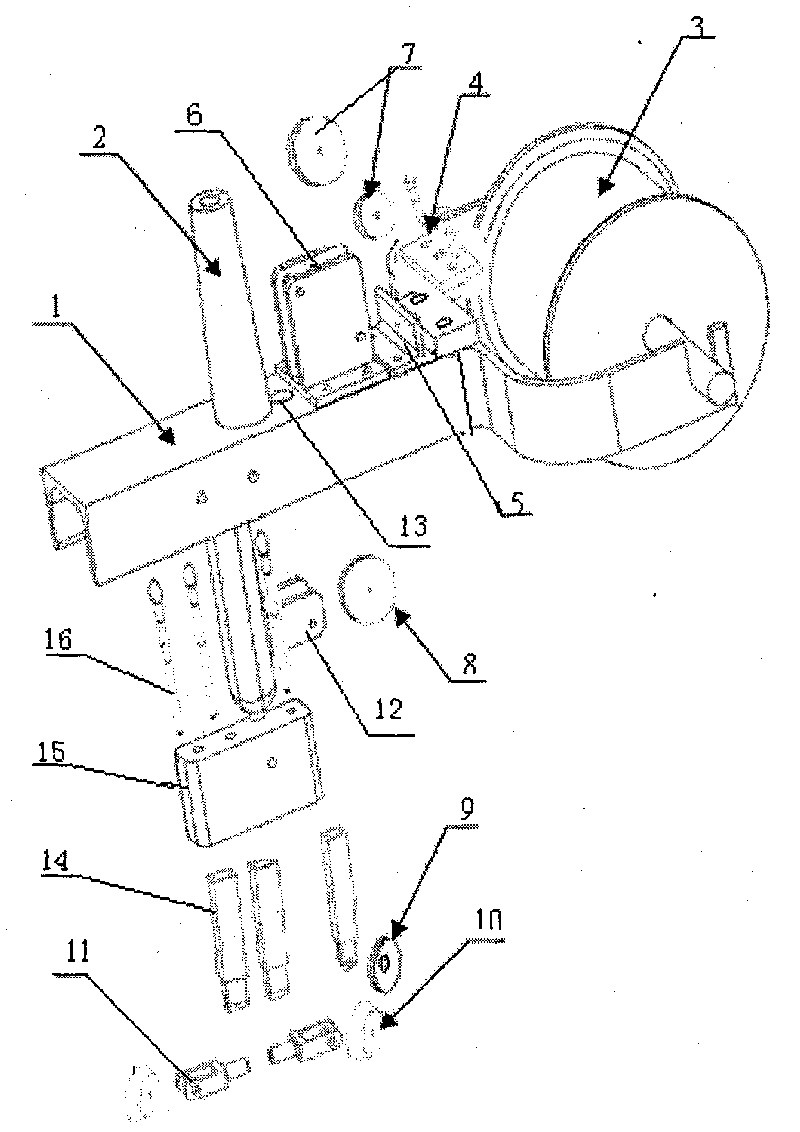

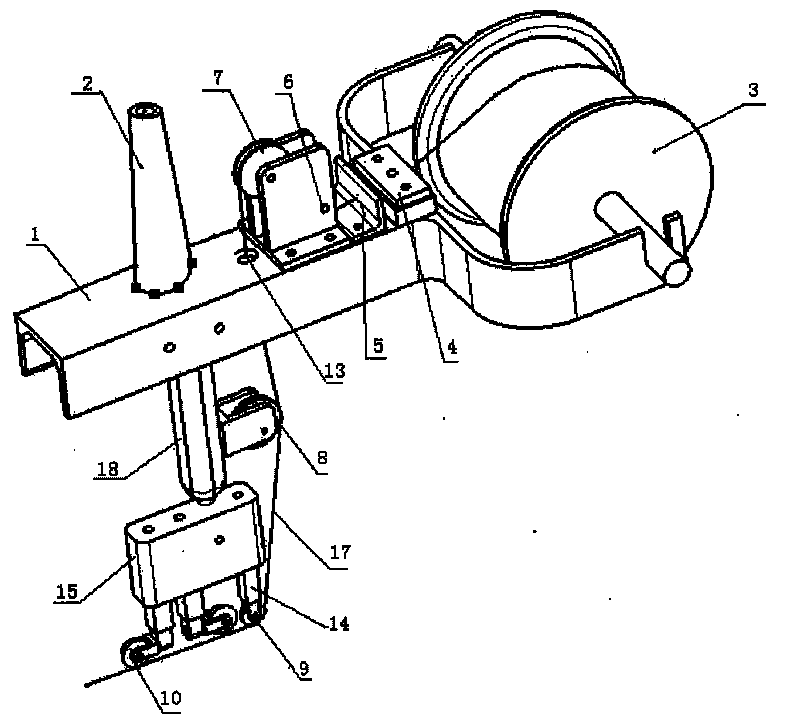

[0020] This embodiment is a wire laying device, which includes a bracket, a wire roller, a tension adjusting plate, a wire mechanism and a wire pay-off mechanism. among them:

[0021] The bracket 1 includes a trough-shaped support rod. At one end of the support rod, a pair of lugs are divided to both sides. The end of the lug has a slot for placing the wire roller 3; the slot is away from the bottom of the lug. The length of is greater than the radius of the wire roller 3, and the width between the two lugs is greater than the axial length of the wire roller 3. The support rod is located at the center of a pair of lugs, and from the position where the support rod and the lugs are adjacent to the end of the support rod, there are tension adjustment plate 4, wire plate 5, double wire wheel group bracket 6, and wire passing Hole 13 and the installation holes of the machine tool connection handle 2, and the positions of the installation holes should be such that the center of the te...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com