Quasi-static calibration device for multichannel stress pressure sensors

A pressure sensor and strain-type technology, which is applied in the field of quasi-static calibration devices for multi-channel strain-type pressure sensors, can solve the problems of static calibration of pressure sensor errors, low efficiency, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

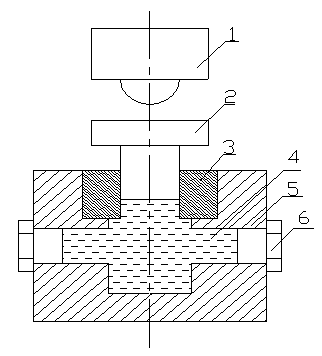

[0009] A quasi-static calibration device for a multi-channel strain type pressure sensor, comprising: an oil cylinder 5, a piston 2, hydraulic oil 4, and also includes: a weight 1, a piston adapter 3 and a calibrator 6. The oil cylinder 5 is placed on a horizontal platform, and there are one or more mounting threaded holes at the same height on the side wall of the oil cylinder 5 and one or more sensors to be calibrated are installed correspondingly; the sensors to be calibrated and the calibrator 6 are installed at the same height of the oil cylinder 5 ; The piston adapter 3 is a cylindrical device with external threads, and the piston adapter 3 is threaded with the top of the oil cylinder 5 . The hydraulic oil 4 is injected into the oil cylinder 5, the piston 2 is placed in the piston adapter 3, and the weight 1 is suspended on the piston 2.

[0010] The heavy hammer 1 falls freely from a certain height and hits the piston 2 on the oil cylinder 5 to compress the hydraulic oi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com