Electronic paper display device

An electronic paper display screen and display device technology, applied in static indicators, nonlinear optics, instruments, etc., can solve the problems of high cost of TFT glass, high cost ratio of electronic components, and high cost, so as to broaden the design range and save costs. , the effect of reducing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

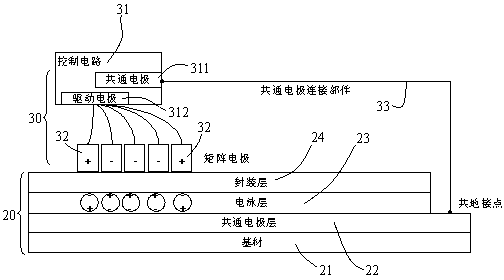

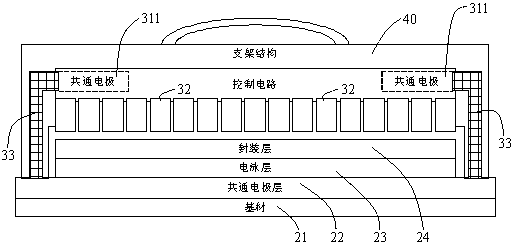

[0025] Please refer to figure 2 As shown, the present invention discloses an electronic paper display device 2, which includes an electronic paper display screen 20 and a driving electrode device 30, and the electronic paper display screen 20 includes a substrate 21, a common electrode layer 22, an electrophoretic layer 23 and a package Layer 24 , the driving electrode device 30 includes a control circuit 31 , a plurality of matrix electrodes 32 controlled by the control circuit 31 and arranged in a matrix, and a common electrode connecting part 33 . The control circuit 31 is provided with a common electrode 311 and a driving electrode 312 . The common electrode connection part 33 connects the common electrode 311 and the common electrode layer 22 . The control circuit 31 is used to output signals to the matrix electrodes 32 so as to apply a driving electric field to the electrophoretic layer 23 , and change the vertical position of the charged particles to display gray scal...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com