Solar cell and preparation method thereof

A solar cell and electrode technology, applied in circuits, photovoltaic power generation, electrical components, etc., to avoid PID effects and improve leakage current problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

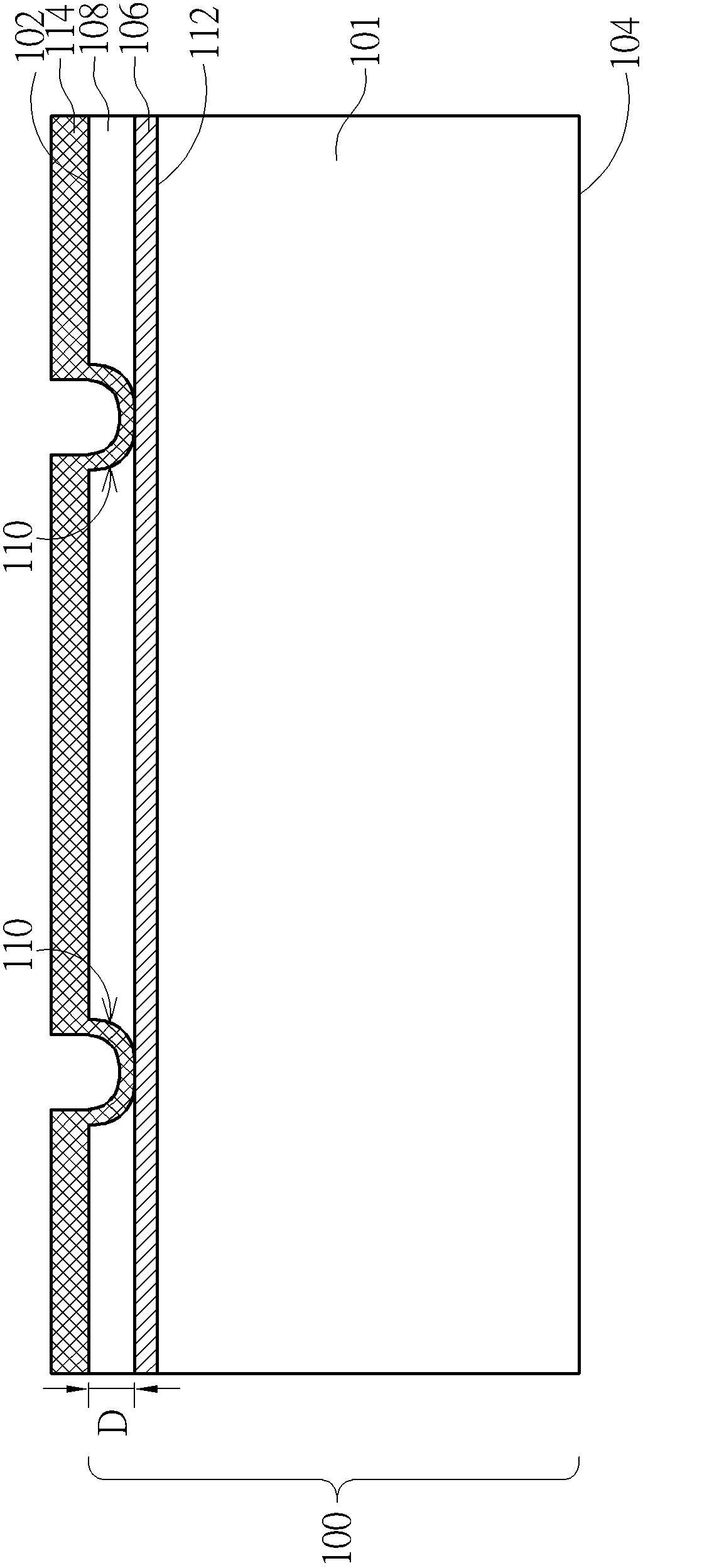

[0055] Similar to the first embodiment, in this embodiment, the substrate 101, the semiconductor layer 108 and the doped region 124 all have the first doping type, while the lightly doped region 106 and the heavily doped region 128 have the second doping type , as opposed to the first doping type. For example, the substrate 101 and the semiconductor layer 108 may have P-type doping, the lightly doped region 106 is N+ type doped, the heavily doped region 128 is N++ type doped, and the doped region 124 is P-type doped , but not limited to this. In other embodiments, the substrate 101 and the semiconductor layer 108 may also have N-type doping, the lightly doped region 106 is P+ type doped, the heavily doped region 128 is P++ type doped, and the doped region 124 is N- type doping.

[0056] Please refer to Figure 10 to Figure 13 It is a process schematic diagram of the third embodiment of the solar cell manufacturing method of the present invention. like Figure 10 As shown,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com