Storage battery production device

A technology for production devices and batteries, applied in secondary battery manufacturing, final product manufacturing, sustainable manufacturing/processing, etc., can solve problems such as affecting the health of residents of battery production companies, affecting the health of workers, and surrounding environmental pollution, etc. Achieve the effect of reducing labor costs, shortening training time, and reducing waste

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

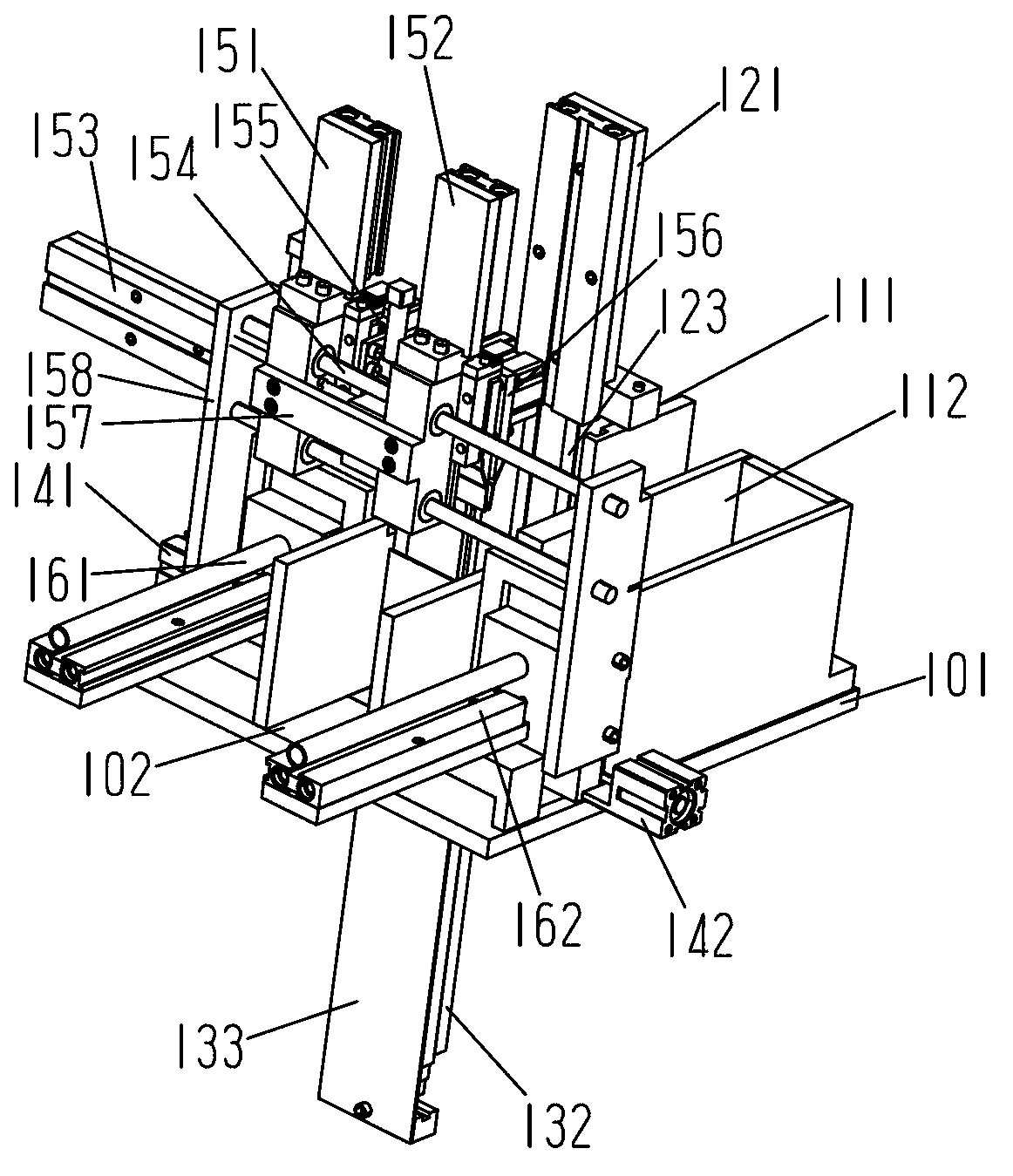

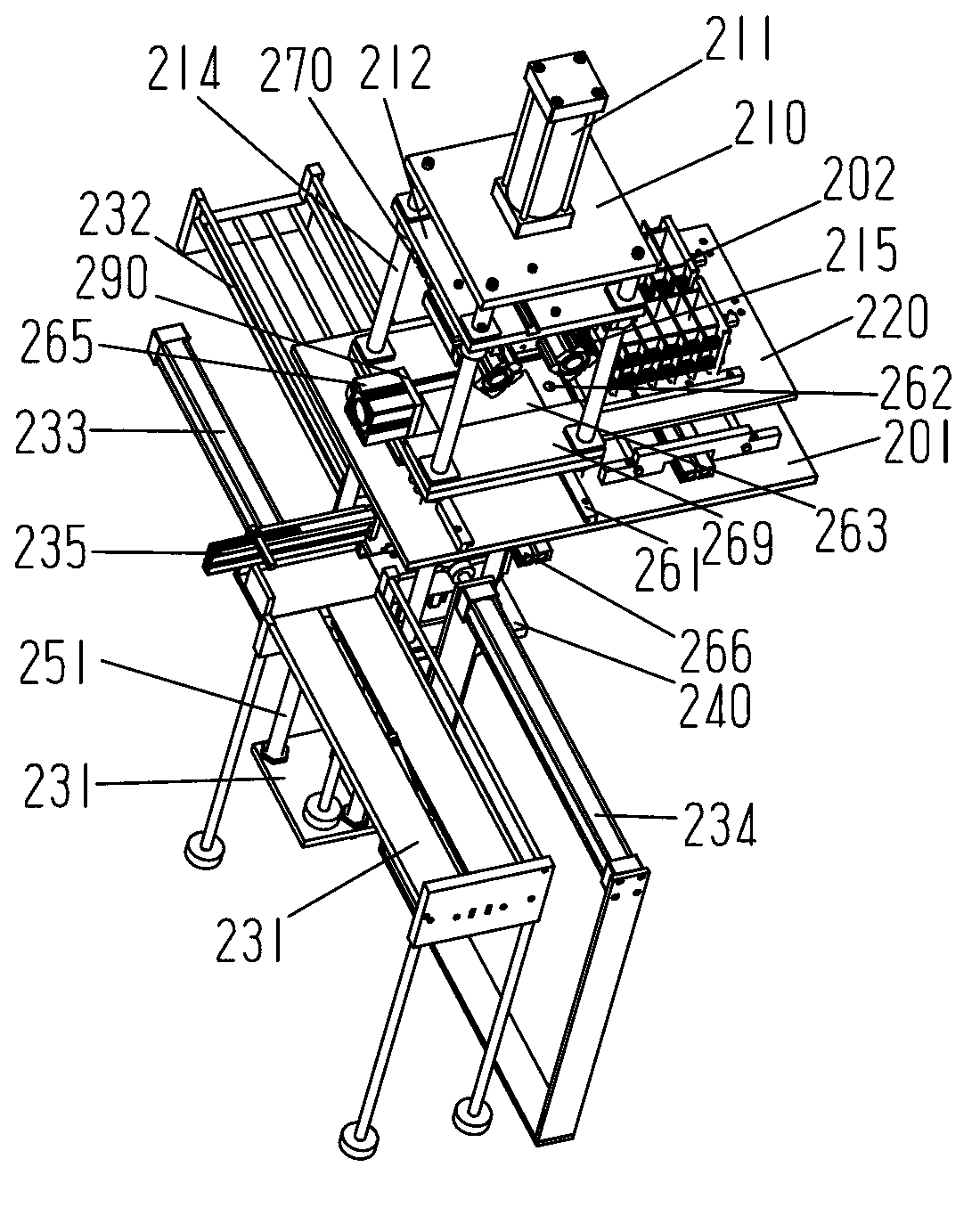

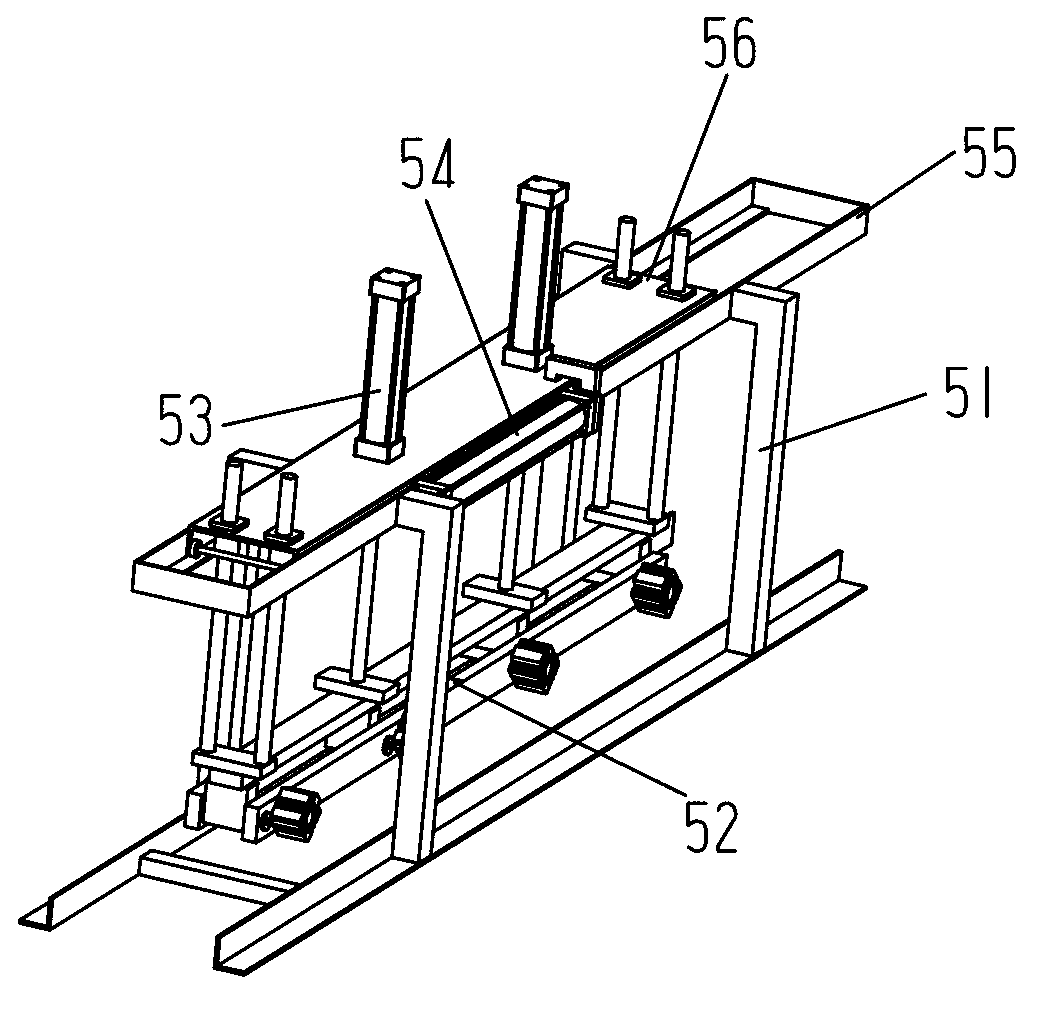

[0024] Embodiment 1, Figure 1~Figure 9 A storage battery production device is given, including a wrapping machine, a slotting machine, a cutting and brushing device, a casting and welding machine and a connecting machine.

[0025] Packing machine includes separator device, electric control device for wrapping machine, plate placement device, felt folding guide device, felt folding device, plate positioning device, plate feeding device, suction plate device, pole group outlet 102 and bottom plate 101.

[0026] The electrode plate placement device includes a negative electrode plate placement groove 111 and a positive electrode plate placement groove 112; the folding felt guide device includes a guide cylinder 121 and a guide sleeve (the guide sleeve is a hollow part, and when in use, it is necessary to pre-set the separator paper on the guide sleeve. , insert the separator paper into the separator device first, then pull out one end and insert it into the guide sleeve); the fol...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com