Hall-free method for starting servo motor

A technology of servo motor and electrical angle, applied in the direction of electronic commutator, starting device, etc., can solve the problems of sewing machine not running and motor not starting, etc., and achieve the effect of high production efficiency and simple and convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] A method for starting a servo motor without a hall of the present invention comprises the following steps:

[0018] Step 1, the method is to provide the torque base vector in turn by perturbing the servo motor;

[0019] Step 2. According to the steering result fed back by the incremental encoder, determine the electrical angle sector where the rotor is located at this time, and give the initial value of the electrical angle, and then transfer to conventional field-oriented control; this method only needs to A small perturbation test when the power is turned on will hardly affect any normal operation of the sewing machine, so it is suitable as an emergency treatment method when a hall sensor is damaged and the sewing machine cannot be used.

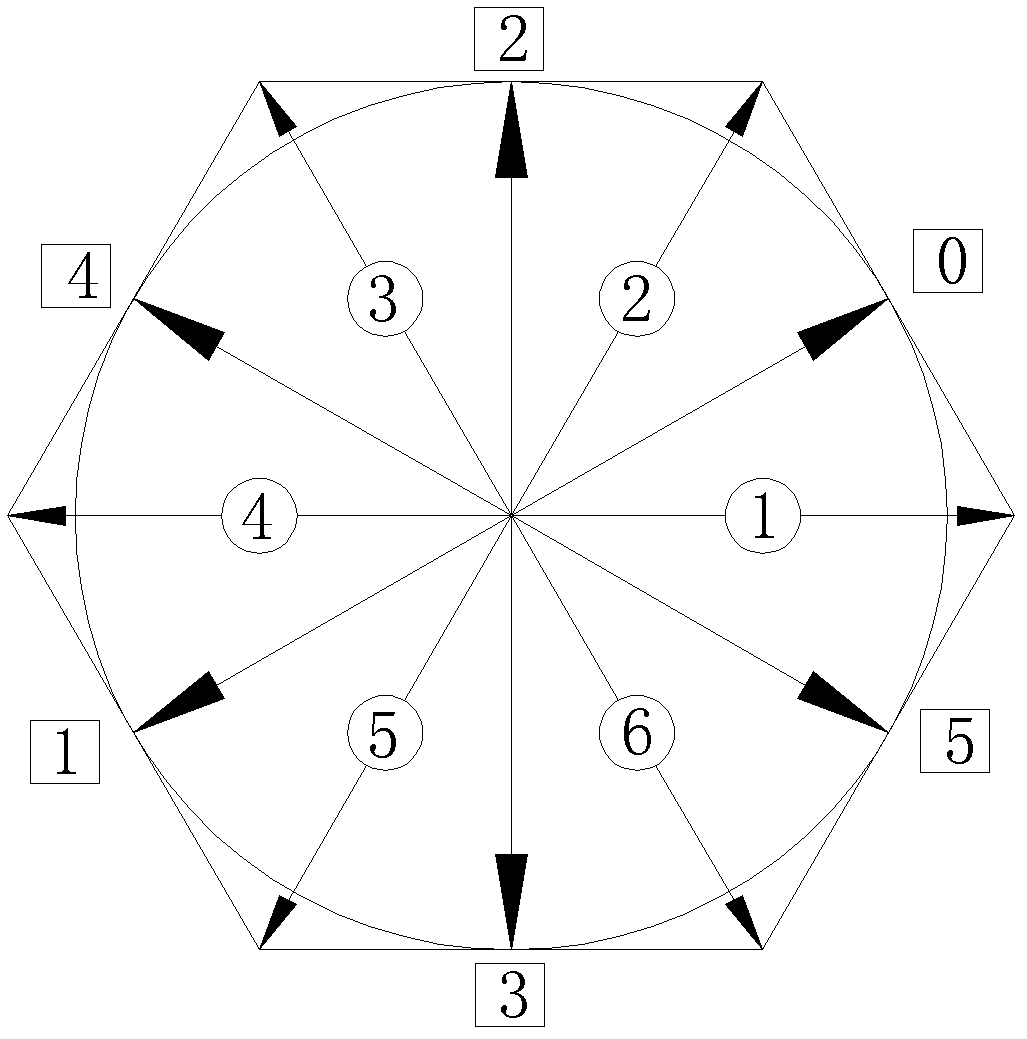

[0020] Such as figure 1 As shown, a hallless servo motor starting method, the specific steps are:

[0021] 1) The motor divides the initial position of the rotor into 6 areas, and the voltage vectors corresponding to 0, 1, 2, 3, 4...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com