Tread feed rack and feed method thereof

A feeding rack and tread technology, which is applied in the field of rubber machinery, can solve problems such as tread offset, error, and impact on tire uniformity, and achieve the effects of improving production efficiency and automation, relieving labor load, and improving uniformity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

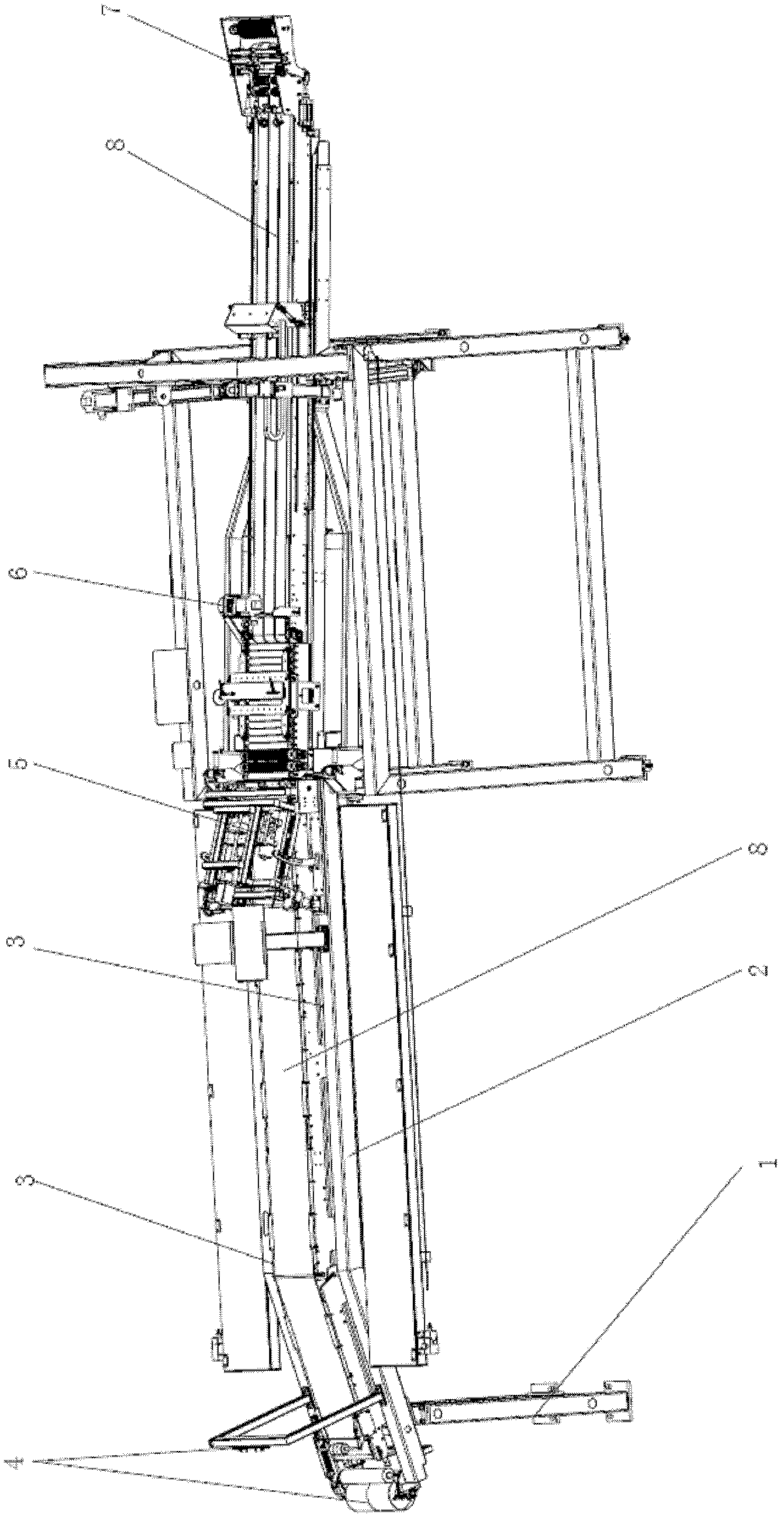

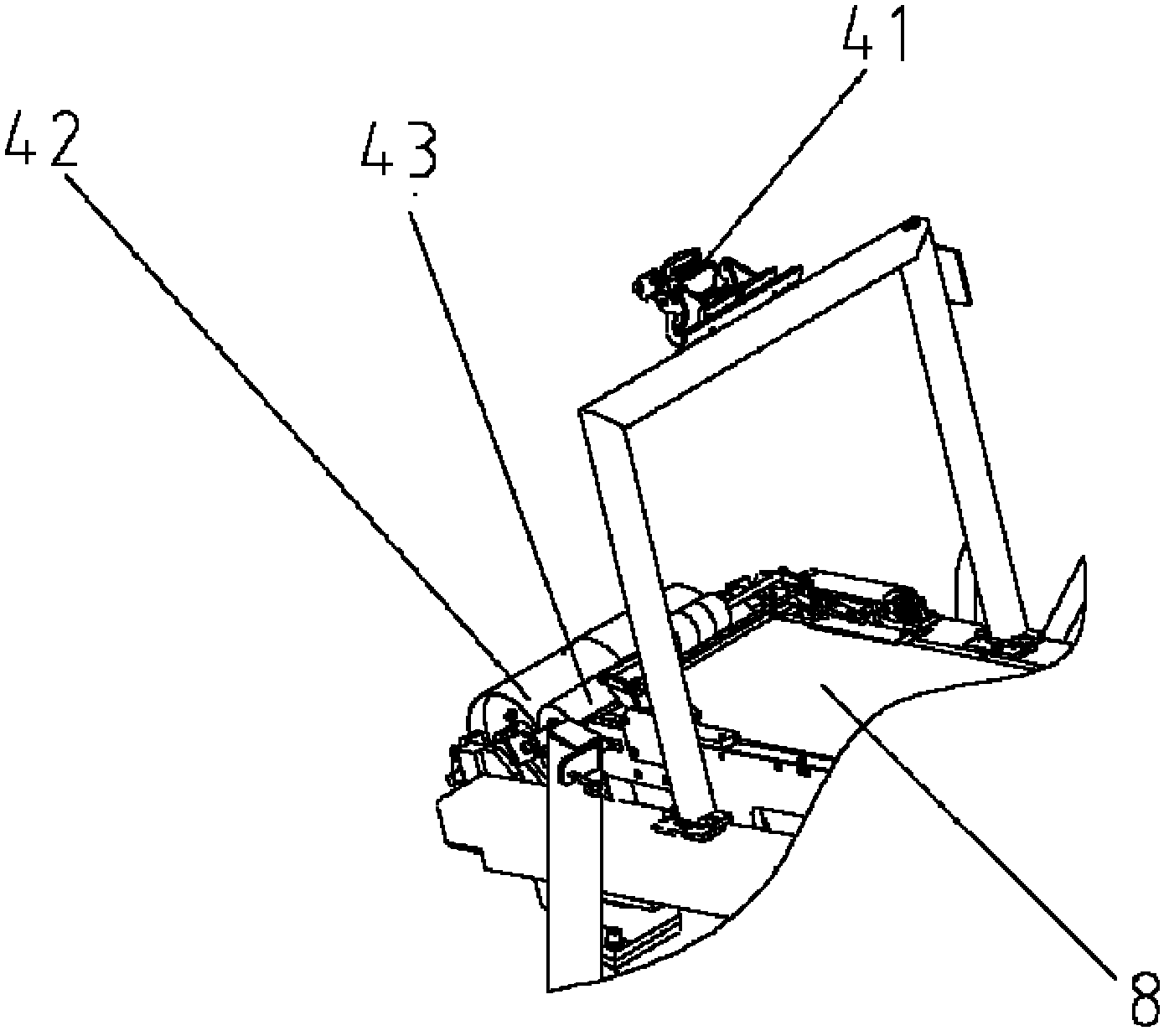

[0047] Example 1, such as figure 1 As shown, the tire tread feed frame of the present invention includes a frame 1 that plays a role of foundation fixed support, and a delivery formwork 2 for delivering the tread to the belt drum, wherein the delivery formwork 2 includes There are two side frames 3, a conveyor belt 8, and an automatic deviation correction mechanism 4, a cutting mechanism 5, a length measuring mechanism 6, a laminating roller mechanism 7, and a conveyor belt arranged in sequence between the two side frames 3 along the tread conveying direction. 8 is a synchronous belt driven by a servo motor.

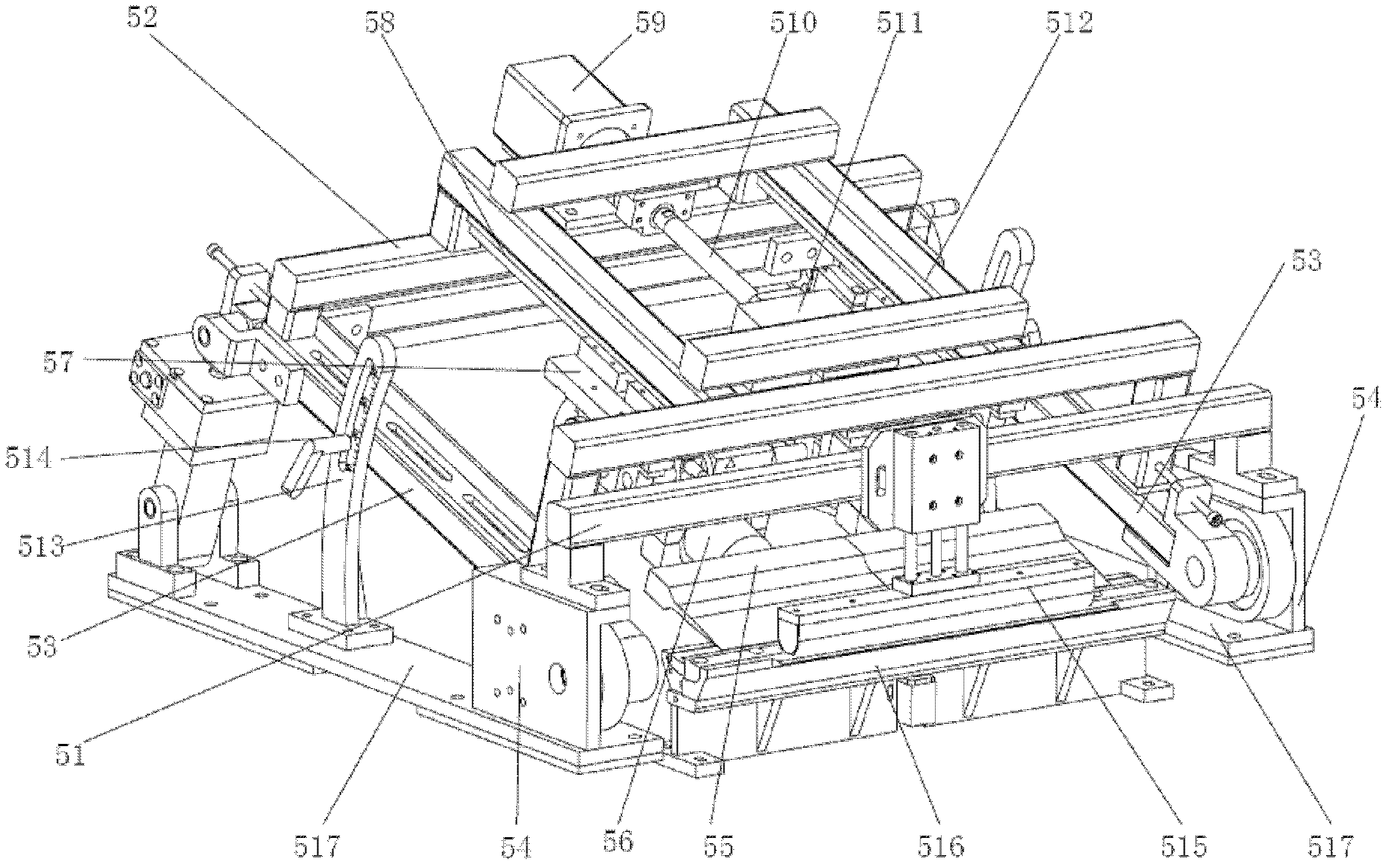

[0048] like figure 2 As shown, the cutting mechanism 5 includes a fixed bracket 51 and a swing bracket 52 , and the fixed bracket 51 is fixed on the side frames 3 of the conveying template 2 through the bottom plates 517 on both sides. Swing arms 53 are arranged on both sides of the swing bracket 52 , and the lower ends of the swing arms 53 are pivotally connected wit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com