Glass cutting apparatus

A glass cutting and glass substrate technology, applied in glass cutting devices, glass manufacturing equipment, manufacturing tools, etc., can solve problems such as operator injury and glass substrate contamination

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

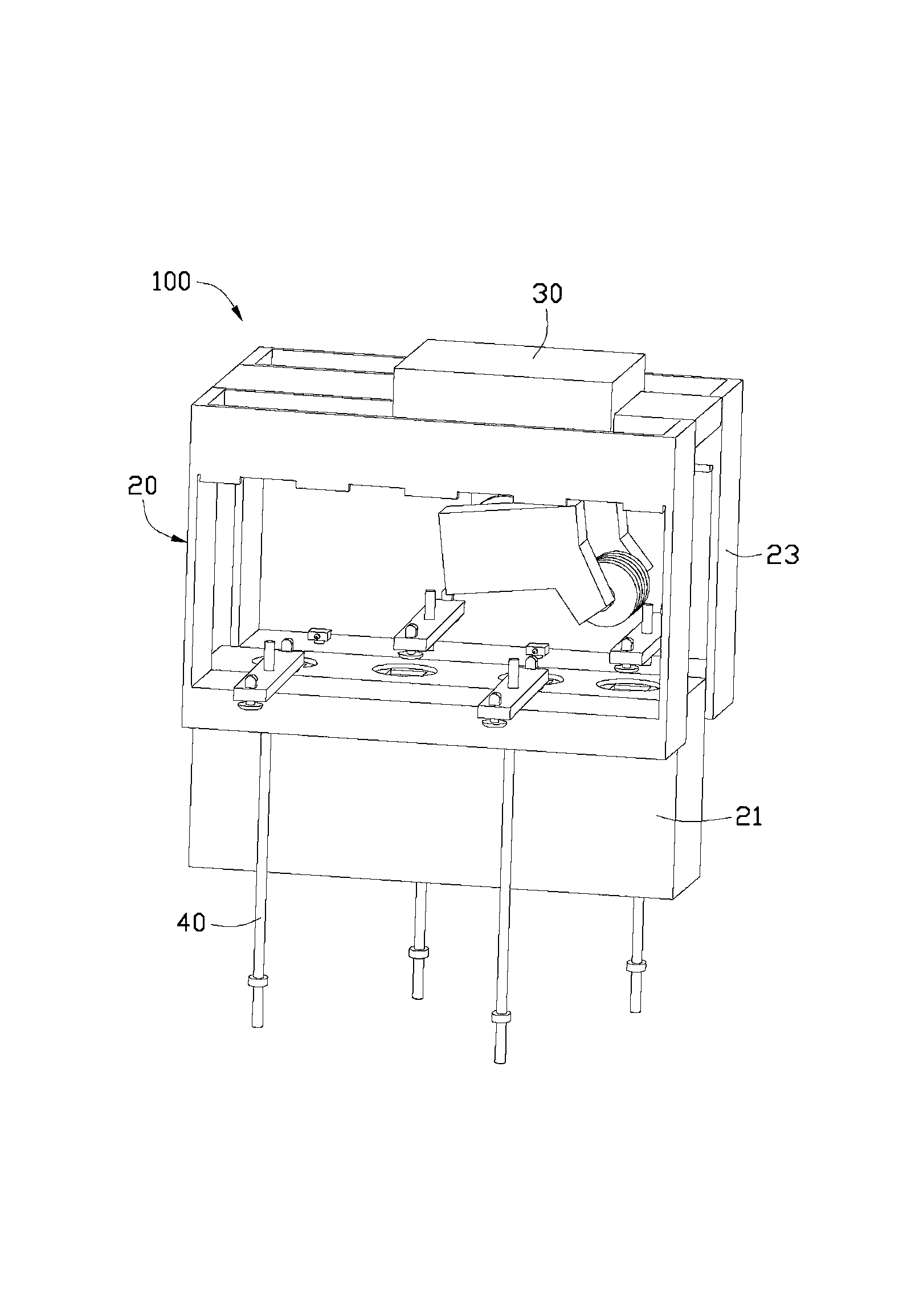

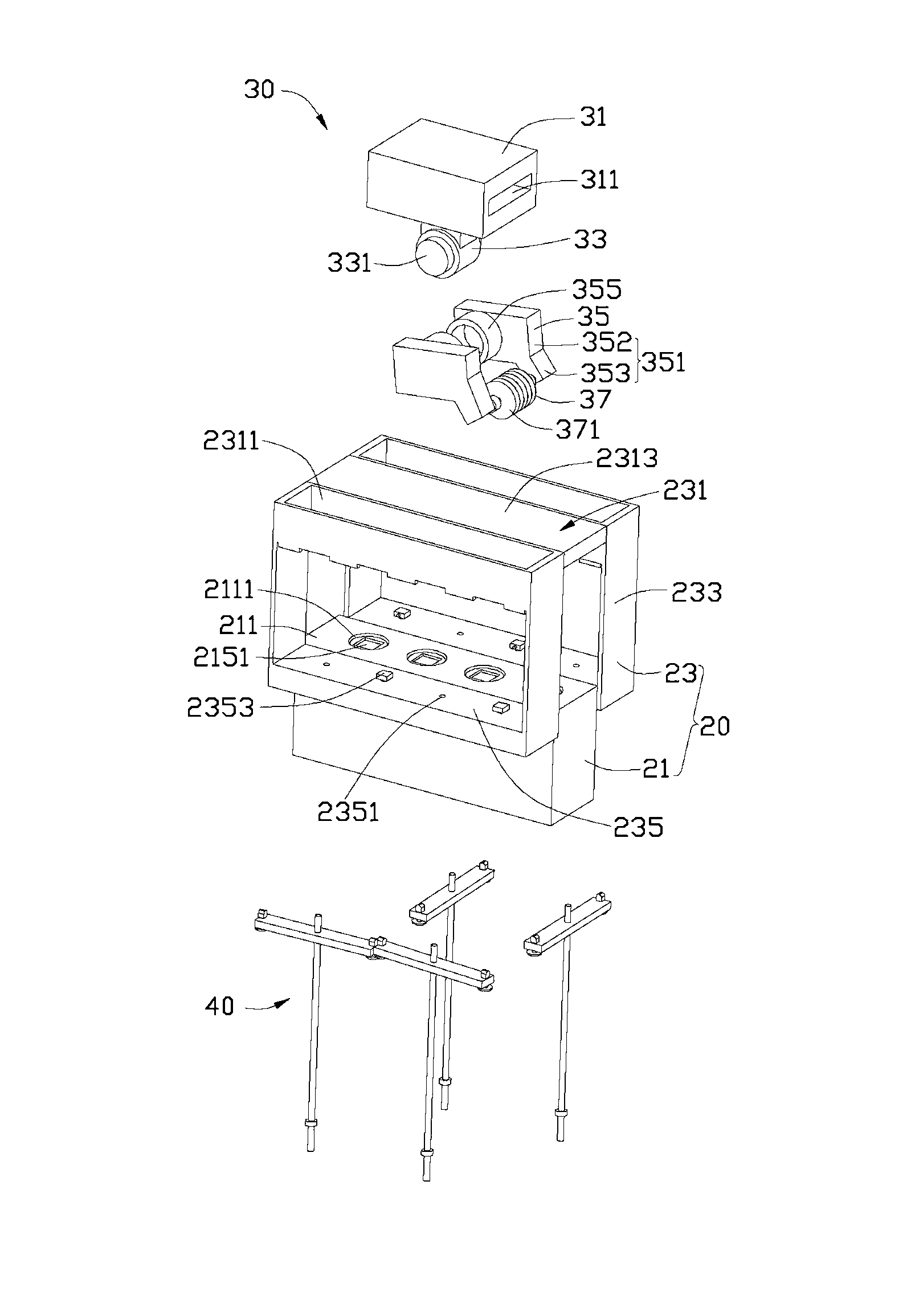

[0013] See figure 1 and figure 2 , The glass cutting device 100 of the embodiment of the present invention includes a worktable 20, a cutting mechanism 30, and a plurality of removing mechanisms 40. The cutting mechanism 30 is slidably arranged on the upper part of the worktable 20, and a plurality of removal mechanisms 40 are rotatably arranged on both sides of the worktable 20. The removal mechanism 40 is used to place the glass substrate to be processed (not shown) on the worktable 20 for the cutting mechanism 30 to cut the glass substrate to be processed. After the cutting is completed, the removal mechanism 40 removes the processed glass substrate. The other glass substrates to be processed are placed on the workbench 20, and so on.

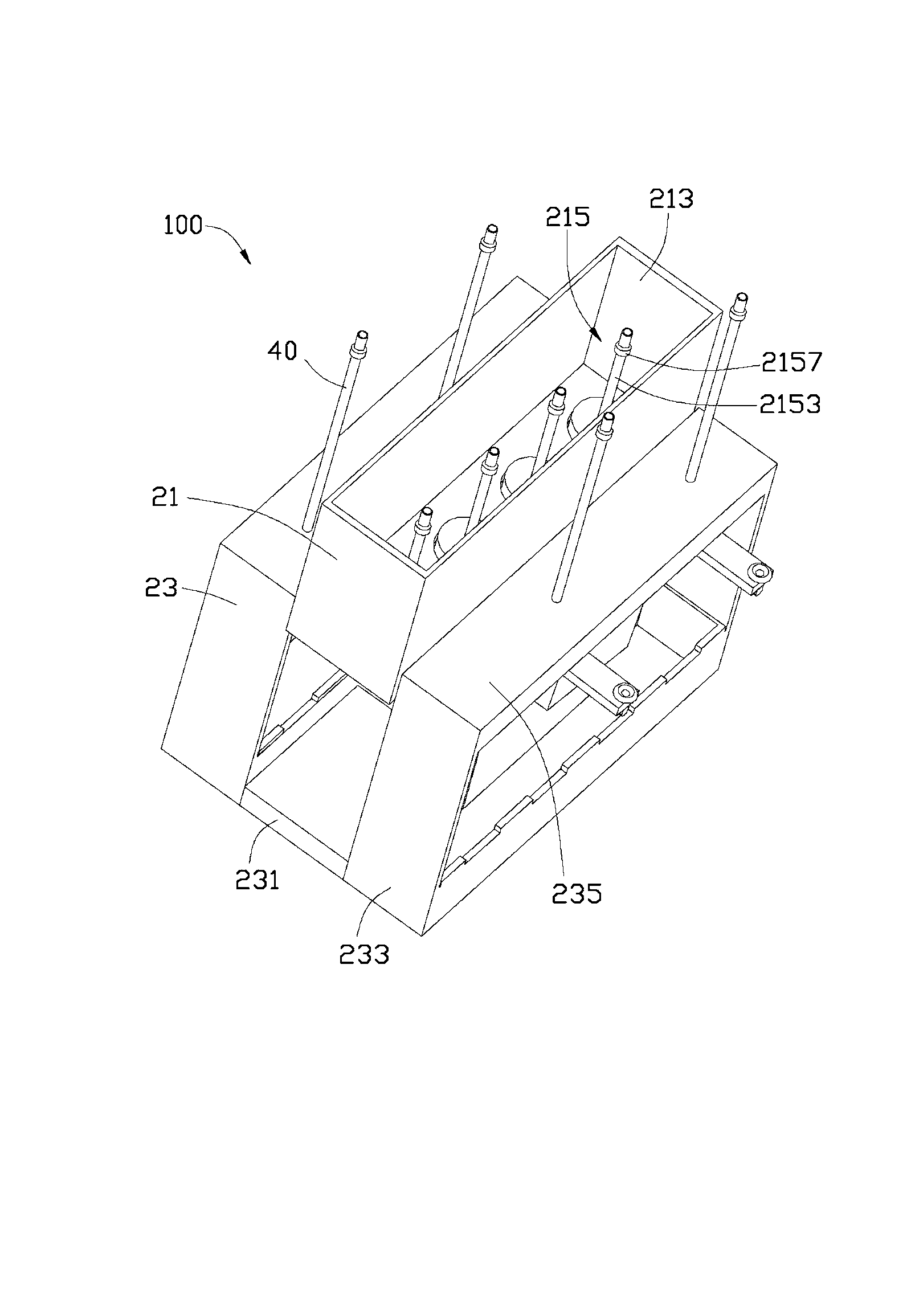

[0014] The workbench 20 includes a base 21 and a frame 23 fixedly arranged on both sides of the base 21.

[0015] See also image 3 The base 21 has a rectangular parallelepiped box-like structure, which includes a working surface 211, a receivi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com