Bamboo decorative composite board and manufacturing method thereof

A manufacturing method and technology for composite panels, which are applied in the direction of flat products, building structures, other household appliances, etc., can solve problems such as unfavorable handling, installation and use, restricting the development and utilization of bamboo materials, and inability to process bamboo laminates, etc. Ecological and ornamental value, simple structure, low cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

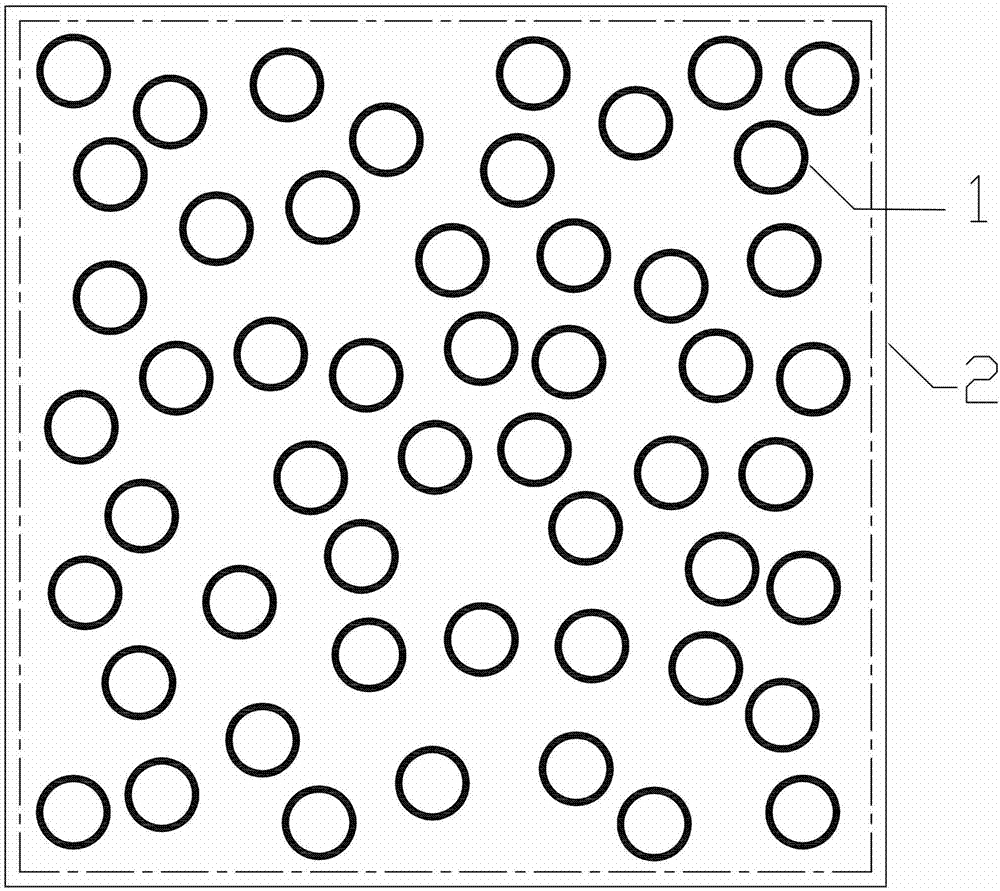

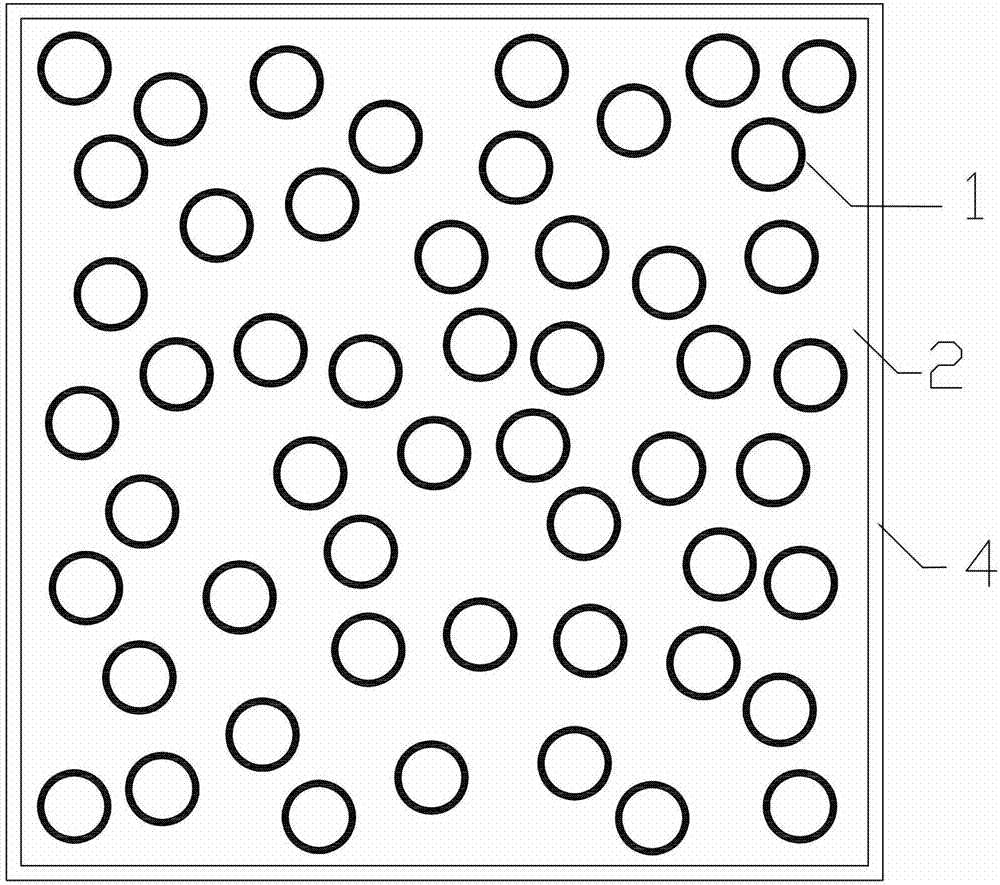

[0036] Such as figure 1 As shown, a kind of bamboo decorative composite board of the present invention comprises base plate 2 and some short bamboo tubes 1 that are installed on one surface of base plate 2, and the axis of short bamboo tube 1 is perpendicular to the surface of base plate 2 (referring to Figure 8 ), the shape of the short bamboo tube 1 is a cylinder, and the short bamboo tubes 1 are arranged on the surface of the substrate 2 in a random and arbitrary shape. Of course, the arrangement of the short bamboo tubes 1 is not limited to figure 1 As shown, different arrangements can be designed according to requirements to reflect various design styles and meet various decoration needs.

[0037] In the present embodiment, the short bamboo tube 1 is a kind bamboo tube, and it can also be other small-diameter grades or thin-walled bamboo tubes such as green bamboo, bitter bamboo, thunder bamboo, or a combination of the above-mentioned various bamboo tubes.

[0038] The ...

Embodiment 2

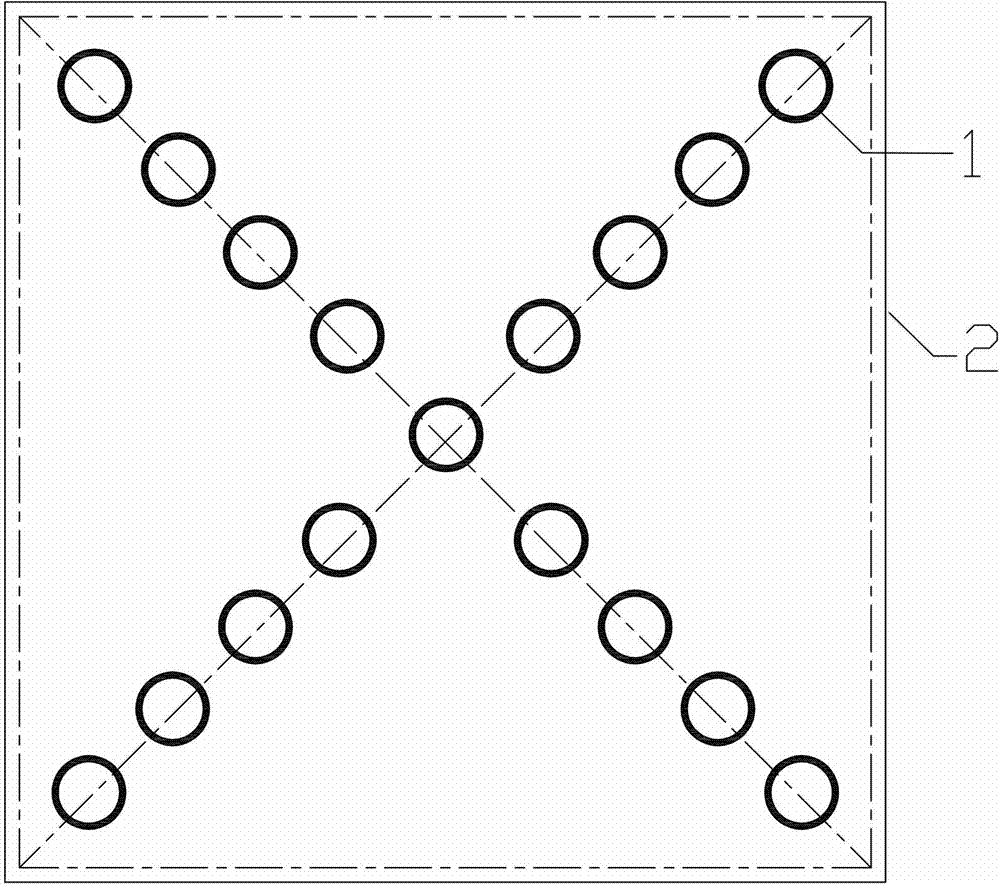

[0047] Such as Figure 5 As shown, a bamboo decorative composite board of the present invention comprises a base plate 2 and several short bamboo tubes 1 installed on one surface of the base plate 2, the axis of the short bamboo tubes 1 is perpendicular to the surface of the base plate 2, and the shape of the short bamboo tubes 1 is a cylinder , short bamboo tube 1 according to Figure 5 The shown diagonal lines are arranged on the surface of the substrate 2 in a cross-shaped manner. In the present embodiment, the short bamboo tube 1 is a philodendron bamboo tube, and the base plate 2 is an acrylic board.

[0048] The manufacturing method of the present embodiment is as follows:

[0049] 1. The processing of the short bamboo tube 1: sawing the dried Cizhu bamboo stalks into long bamboo tubes with a length of 1.5m, placing the long bamboo tubes in a drying room and drying them to a moisture content of 20% at 40°C, then using 5 ℃ / h to 70°C, and then dried at 70°C until the mo...

Embodiment 3

[0054] Such as Image 6 As shown, a bamboo decorative composite board of the present invention comprises a base plate 2 and several short bamboo tubes 1 installed on one surface of the base plate 2, the axis of the short bamboo tubes 1 is perpendicular to the surface of the base plate 2, and the shape of the short bamboo tubes 1 is a cylinder , the short bamboo tubes 1 are arranged on the surface of the substrate 2 in a combination of square and diagonal cross shapes, the periphery is a square layout, and the interior of the square is arranged diagonally with the four vertices of the square as endpoints. In the present embodiment, the short bamboo tube 1 is a philodendron bamboo tube, and the base plate 2 is an acrylic board.

[0055] The manufacturing method of the present embodiment is as follows:

[0056] 1. The processing of short bamboo tube 1: sawing the dried Cizhu bamboo stalks into long bamboo tubes with a length of 1.5m, placing the long bamboo tubes in a drying roo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com