Continuously variable valve lift device

A variable valve lift technology, applied in the direction of valve devices, machines/engines, mechanical equipment, etc., can solve the problems of large space occupation and low reliability, and achieve small space occupation, high reliability, and compact device structure Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

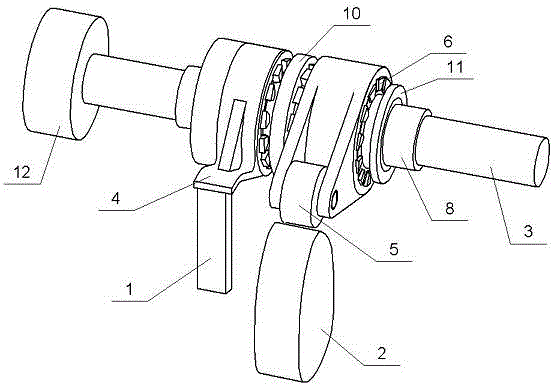

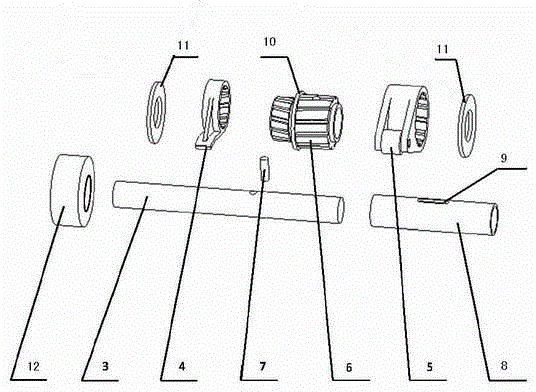

[0019] A continuously variable valve lift device, such as figure 1 and figure 2 As shown, it includes a valve assembly 1, a cam 2 and an axially movable control shaft 3. The control shaft 3 is covered with two helical gears linked with it. The teeth of the two helical gears are inclined in opposite directions. One helical gear is provided with The swing rocker arm 4 adapted to it is provided with a roller rocker arm 5 adapted to it on the other helical gear, and the opposite end faces of the two helical gears are connected to form an integrated combined gear 6. The combined gear 6 and the radial direction of the control shaft 3 are provided with pin holes, the combination gear 6 and the control shaft 3 are connected through the fixed pin 7 inserted into the pin hole, a conduit 8 is set between the control shaft 3 and the combination gear 6, and the conduit 8 Fixedly installed, the guide tube 8 is provided with a bar-shaped hole 9, the length direction of the bar-shaped hole ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com