Application method of an oil production string

A technology for producing pipe strings and application methods, which is applied in the direction of drilling pipes, casings, and production fluids. It can solve problems such as inability to work, formation crude oil cannot be lifted to the ground, and achieve the effect of reducing investment costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

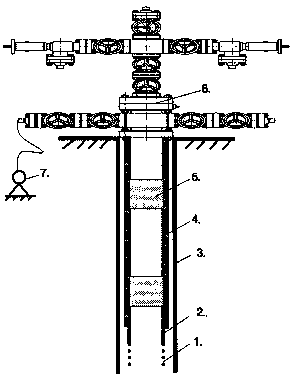

[0022] In order to solve the problem that the oil pump in the lifting string of the high gas production well is gas-locked and unable to work, resulting in the inability of the formation crude oil to be lifted to the ground, this embodiment provides an oil production string, including The self-spraying oil production wellhead 6, the casing tee of the self-spraying oil production wellhead 6 is connected with a plurality of capillary steel pipes 4, and all the capillary steel pipes 4 extend downward to the annular space between the tubing 2 and the casing 3 Inside, the outer wall of one side of the capillary steel pipe 4 is bonded to the outer wall of the oil pipe 2. The oil pipe 2 is composed of a plurality of oil pipe nipples, and a foaming device 5 is installed between adjacent oil pipe nipples. The end of the capillary steel pipe 4 is fixed on On the lowermost foaming device 5 , the lower end of the oil pipe 2 is connected with a floral tube 1 , and the floral tube 1 is close...

Embodiment 2

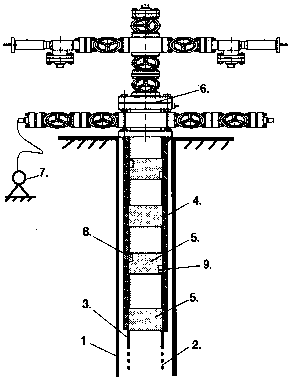

[0029] On the basis of Example 1, the foaming device 5 is provided with an upper liquid inlet hole 8 and a lower liquid inlet hole 9 , and both the upper liquid inlet hole 8 and the lower liquid inlet hole 9 are close to the inner wall of the oil pipe 2 .

[0030] On deep wells, due to the high lifting height, multiple foaming devices need to be installed, and the foaming agent needs to be replenished during the lifting process. This embodiment provides the following figure 2 In the oil production string shown, the plunger pump 7 continuously injects foaming agent into the capillary steel pipe 4, and the foaming agent gradually flows downward along the capillary steel pipe 4, and a part of the foaming agent follows the upper liquid inlet hole 8 and the lower liquid inlet. The hole 9 flows to the foaming device 5; a part of the foaming agent flows directly along the capillary steel pipe 4 into the annular space between the oil pipe 2 and the casing 3, and forms a mixed liquid w...

Embodiment 3

[0034] On the basis of Embodiment 2, the foaming device 5 is composed of a housing, a helical stirrer and a storage lithium battery in the housing, and the helical stirrer is electrically connected to the storage lithium battery.

[0035] The steel grade and outer diameter of the foaming device 5 are the same as those of the oil pipe 2, the length is 10 meters, and the connection with the oil pipe 2 is realized by a screw. There is a spiral stirrer inside the foaming device 5, and the driving force of the stirrer is provided by a storage lithium battery. When the fluid containing the foaming agent flows through the foaming device 5, the stirrer will automatically start when it senses the flow of the liquid, making the liquid The foaming agent quickly turns into a large amount of foam, and the foam carries the crude oil in the wellbore, and boosts the fluid in the wellbore through the tubing to go up to the head of the self-spraying production well.

[0036] The specific number...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com