Method for improving arc discharge defect in mim capacitor fabrication

A technology of arc discharge and capacitors, which is applied in semiconductor/solid-state device manufacturing, circuits, electrical components, etc., can solve problems affecting the yield of semiconductor integrated circuits, etc., and achieve the goal of improving arc discharge defects, avoiding arc discharge defects, and improving yield Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

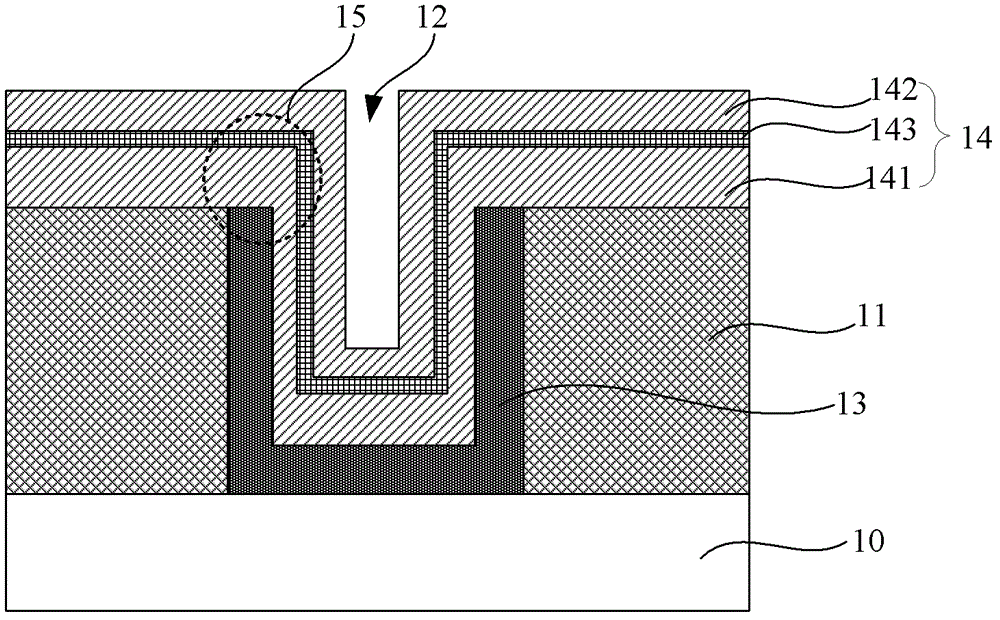

[0028] The method for improving the arc discharge defect in the manufacture of MIM capacitors proposed by the present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

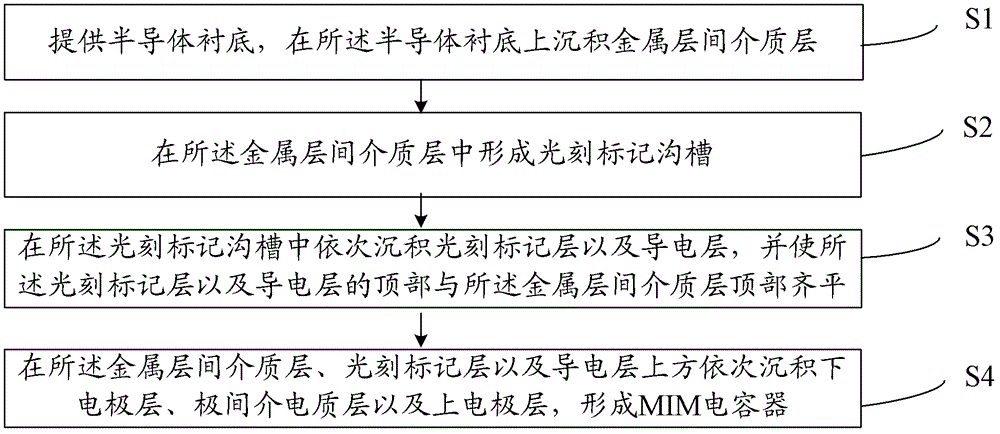

[0029] Such as image 3 As shown, the present invention proposes a kind of method for improving the arc discharge defect in MIM capacitor making, comprising:

[0030] S1, providing a semiconductor substrate, and depositing an inter-metal dielectric layer on the semiconductor substrate;

[0031] S2, forming a photolithography marking groove in the inter-metal dielectric layer;

[0032] S3, sequentially depositing a photolithographic marking layer and a conductive layer in the photolithographic marking groove, and planarizing to the inter-metal dielectric layer;

[0033] S4, sequentially depositing a lower electrode layer, an interelectrode dielectric layer, and an upper electrode layer on the intermetal dielectric layer and the filled c...

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com