Apparatus and method for conveying fluid into sliver and slivers with such an arrangement

A technology of fluid conveying and sliver forming machine, applied in the direction of spraying device, spraying device, spraying device with movable outlet, etc., can solve the problem of time-consuming structure, increase the diversity of components, etc., and achieve the effect of simple and reliable transportation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

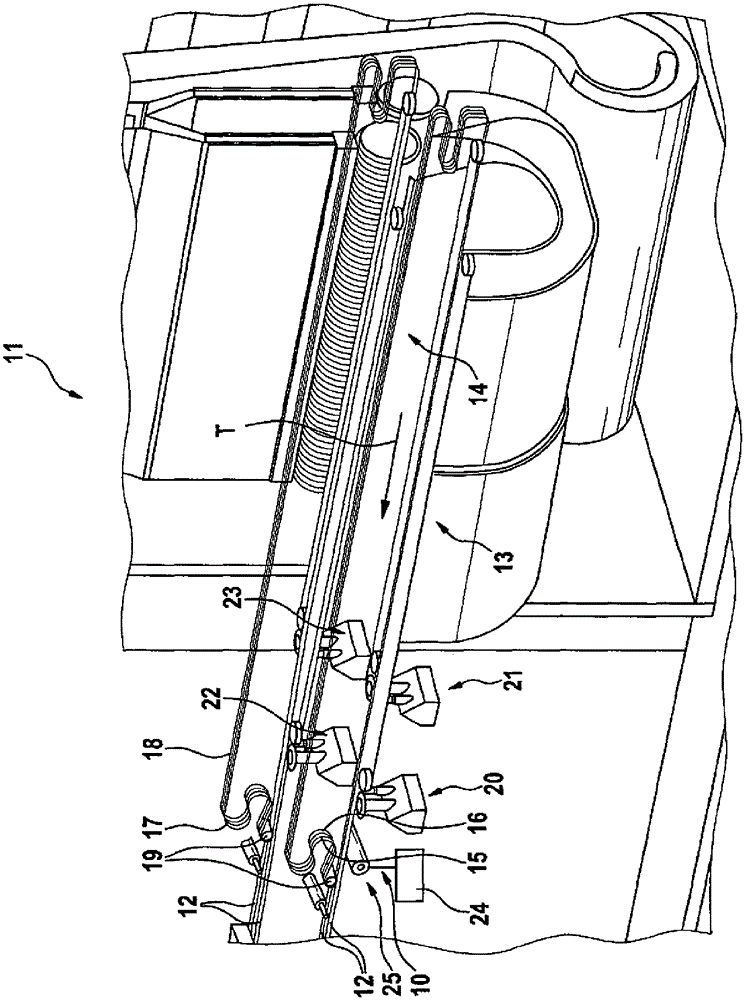

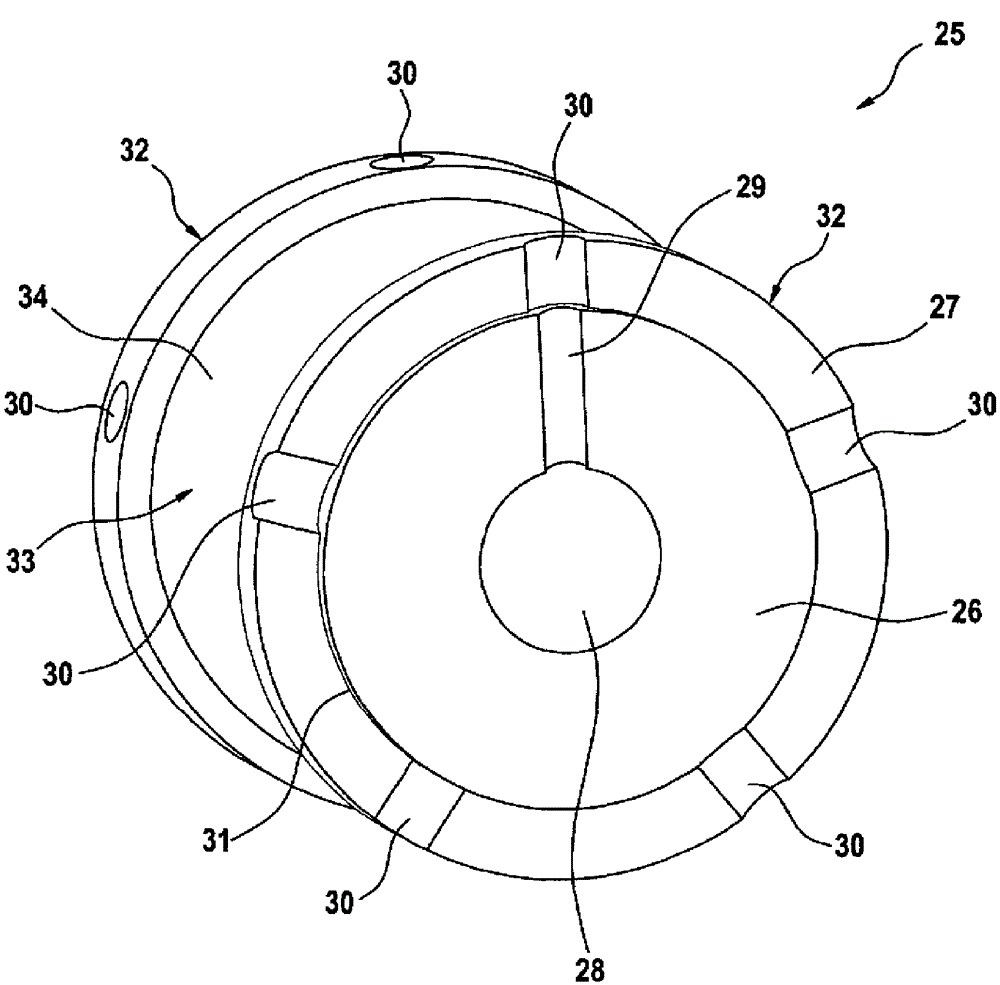

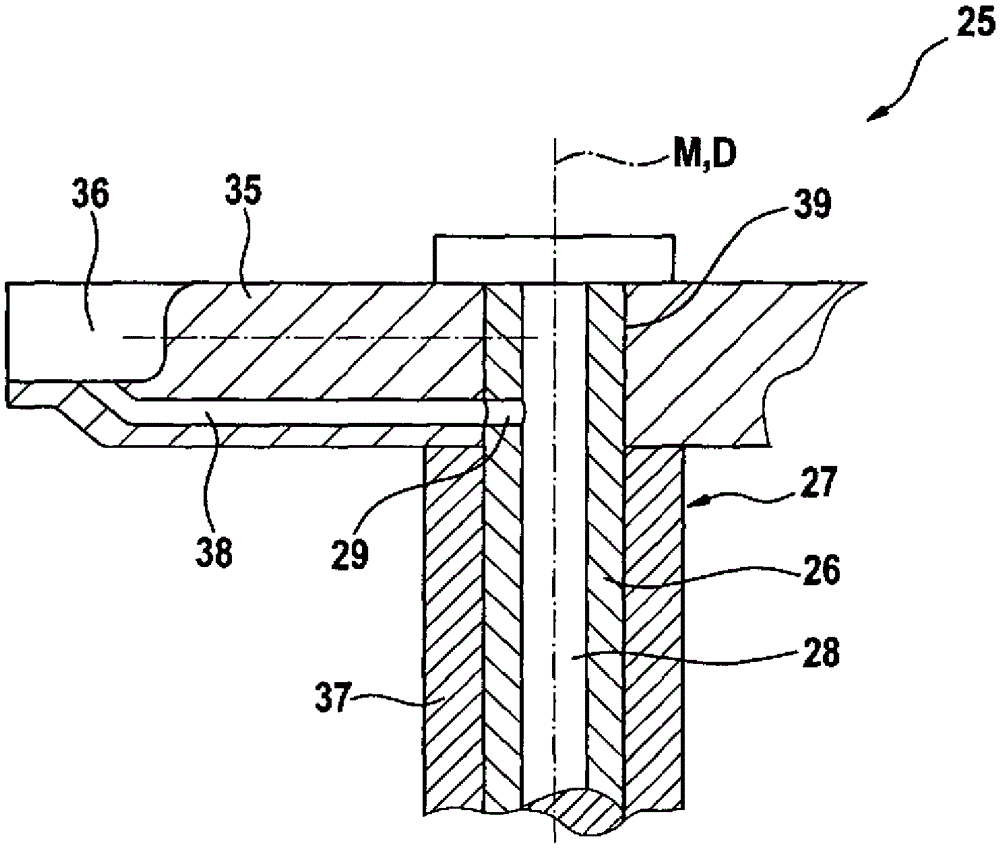

[0025] The devices and embodiments shown in the figures are used to deliver fluids to tobacco rods. Of course, the devices and embodiments described are also manufactured and arranged for delivering fluid to filter rods or rods made of another material or a combination of materials for the tobacco processing industry. Furthermore, the device can be used for fluid delivery for single, double or multiple sliver machines.

[0026] The device 10 according to the invention for conveying fluids can be used as a stand-alone device (component, fitting, retrofit kit, etc.). However, the device 10 is usually an integral part of the sliver 11 . In order to understand the present invention better, therefore first according to figure 1 A rod forming machine 11 well known in the tobacco processing industry, namely a four-rod cigarette rod forming machine, is described in part, a detailed description of the basic processing elements being omitted.

[0027] The material to be processed int...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com